-

Posts

2366 -

Joined

-

Last visited

-

Days Won

27

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by madkaw

-

Pro/Con of combining valve cover and engine breathers

madkaw replied to zredbaron's topic in Nissan L6 Forum

I found that using my vacuum log to hook up my pcv was great until my MAP sensor at the bottom of my log collected all my blow by. I was not running a catch can, but I will now. I do run my motor hard , so some blow by is to be expected. I have to make a significant mixture change on the triples when using a pcv vs. not using one. -

You need to fill out your signature or be specific with which block, head, etc. I used the head dowels to line things up. Gaskets come in various hole sizes, so I doubt you've ruined anything.

-

-

So learned another lesson the hard way this week. Running my MAP sensor on the vacuum log was a good idea for a signal, but I guess running the PCV on the same log WITHOUT a oil separator of some kind was a bad idea. My engine started running wonky today and timing was way off. Long story short, blow by oil was gathering at my MAP sensor fitting and running down the vacuum hose right to my MS3X unit. When I pulled the line off there quite a bit of oil in the line and I believe ruined my MAP Daddy sensor. I guess I will be making a catch can to run with my PCV, if I run the PCV again. I also need to run the vacuum line for the PCV in the center of my vacuum line instead of one end. The 'controlled' vacuum leak of the pcv causes things to go lean at that end

-

So as I celebrated my tach finally working as i'm driving down the road I notice some pretty significant detonation. Never heard that before, so I drove back home nice and easy. When I hooked my lap top up the gauges showed some really high timing numbers, like 30 at idle. I looked at my timing tables that I just recently adjusted and the timing was right for the rpm. If I revved up the motor at all the gauge was showing 50+ degrees of advance. So I figured I screwed up something when installing the MSD and proceeded to disconnect everything, still crazy timing numbers. As I'm tugging on wires I notice my vacuum line for the MAP sensor is falling off. I pulled it the rest the way off and got a hand full of oil. My MAP sensor is in the middle of my vacuum log. I also have the PCV at one end of the vacuum log. So i'm guess I have or had significant blow by and it accumulates at the lowest point, which down the vacuum log to my MS unit. I guess the MAP sensor is toast. I tried cleaning it, but no luck

-

Got my tach working FINALLY. I didn't try real hard at first, but I had a MSD 8920 and wasn't getting it to work . I chased wires by pulling the tach to make sure I had correct ones- still didn't work. My dumb ass didn't know that you had to turn on the tach output on tuner studio. Now tach works. Time to head to the dyno!

-

Twin cam head for the L6 from Derek at Datsunworks

madkaw replied to Derek's topic in Nissan L6 Forum

It's been just over a year since you started this thread. I think your pace has been anything but slow. I don't know how you have had time to do anything else in your life. There's guys on here that spend this long just assembling a motor, let alone designing, fabricating and actual assembly. Looks great. Getting so close. -

I guess there isn't many mikuni gurus here anymore. Anyhow, I took the #1 carb off again looking for possible air leaks. I looked over the plastic insolators for cracks, but found only some warpage of the insolators. You would think that being sandwiched between the intake and carb would flatten it out enough, but maybe not. The O-ring only sits about.3mm above the groove, not much room for error. I decided to take sandpaper to the insolators on a glass table and found a significant low spot on one of the insolators. I magic markered the all the insolators and sanded flat with wet sandpaper. I can now run similiar mixture settings on all the carbs, so it must have helped. Iv'e given up on #6 sputter issue for now. It doesn't effect much and doesn't foul plug, just makes that plug slightly darker. Last day of running hard I couldn't see a difference in any of the plugs. I can watch the AFR's bobble a bit rich----dam gauge, I'm obsessed. Time to go to the dyno! Current settings 65 pilots 1.5 turns 200 main airs 145 mains Afr WOT in 3rd is spot on-13.5, but 4th seems a bit rich 12.5 ish. I guess thats normal. I might need to drop to 140's for the dyno. Third gear is all the fun with this car since I can get 100mph out of it, so i have mostly tuned WOT for it. My AFR might be a bit skewed from #6 dribble, so I need(make mental note) to swap back wideband to from 3 cylinders.

-

Picking up a complete runner tomorrow. I'm only wanting crank and trans, so PM me . I didn't want to be in a hurry to part this out, but for the right price I would step up the process. This would ship from indiana.

-

I bet you miss the L gata , but good luck.

-

I am changing my suspicion of the sputtering to the pilot mixture . I can dial in the mixture screw until the sputter goes away, but then it's about to lean to run. Not sure what's going on so I guess I will yank the carb off and look inside the mixture hole. Any ideas?

-

Damn, I'd like to just find one TB cheap, and you got 6- lol You would run a MAP sensor of some kind would be easiest.

-

Still plugging away here with carb tuning. Swapping around the wideband to the other bank of exhaust ( advantage of duals), from the back to the front cylinders I noticed the front carbs were starving. The odd thing is that I have to run the mixture screws 1/2 turn richer to get a smooth idle. So I suspect air leak, but can't pin anything down. I have replaced all O-rings ( 50mm X 2.5mm is what I found) and not much difference. Sprayed down everything with starter fluid with no response. now I can live with this because I can tune it in and the motor runs really well-- -EXCEPT for #6. By looking at the plugs 6 is sputtering rich with small black spots diluting the tan underneath. I can use a hose and listen inside the carb inlet and hear the sputtering occurring. I suspect it's the accelerator pump leaking fuel by the packing, though I have changed it once already. With a mirror I can see nothing happening on my side of the butterfly. Trying to come up with an idea to seal off the accel chamber to verify this issue. I've looked down the accel pump hole and can't see any obstruction to keep packing from sealing. Anyone ever try an Oring to seal the pump? I tried tightening the cap as much as I care too, since I know this isn't the way it was made to seal.

-

Putting together a FI set up and looking for a 240sx TB or a TB without a bunch of extra plumbing like a zxt TB

-

Twin cam head for the L6 from Derek at Datsunworks

madkaw replied to Derek's topic in Nissan L6 Forum

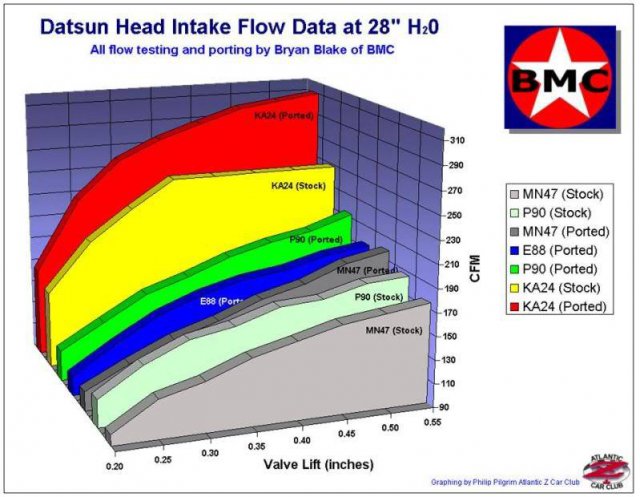

I thought it was your graph. I was interested in the MN47 info for my own project, but it's good for comparison here. Wish I could pick your brain over on the MN47 stuff you did sometime.... but for now, it's Derek's spotlight! -

Twin cam head for the L6 from Derek at Datsunworks

madkaw replied to Derek's topic in Nissan L6 Forum

-

I'm confused, I don't see an option from your choices above for flat top motor, but you keep mentioning it. Yes a P79/54 flat top would be best for na , but your 54 has dish pistons as you stated.

-

Twin cam head for the L6 from Derek at Datsunworks

madkaw replied to Derek's topic in Nissan L6 Forum

Amazing talent to put all this together. Thanks again for documenting all this for us wishers. I feel an extravagant expenditure in my future. Megasquirt is already in place. -

More importantly is whether the Mikuni intake(if you used one) cleared the bolt holding the thermostat housing. The Mikuni shorty intake #1 runner hits the rear bolt of the thermostat housing. You might miss this if your not careful. The intake will not seal because it is being held of the head by this bolt. Not sure what you are using that hole for, but doesn't have anything to do with the Mikinis.

-

L28 oil pressure - how much is too much?

madkaw replied to ryant67's topic in Trouble Shooting / General Engine

I had the mysterious high oil pressure on my last l24, the thread is on here. Only went away when I changed blocks. Latest L24 runs average numbers. -

I wouldn't trust that head either . Like John said, sell off what you don't want. I had all kinds of issues with SS valves (SI), nothing wrong with stock Nissan valves for street. I'd try the cam, I think it would be plenty streetable. I'd try a P79 or p90 with that cam, no oversized gasket needed.

-

So many factors to consider, but the curve does seem late.

-

My Mikunis are giving me a bit of a fit lately. Strange issue of the car dying or wanting to die at idle. The engine acts like it is running out of fuel. I can watch the AFR gauge slowly but surely go way lean as the engine starts to idle rougher and eventually it will die. It is kind of arbitrary when it happens, at other times it idles okay. In the past I have always been able to have a good idle with these carbs. I installed a fuel pressure gauge so I can drive and watch, because I am still dealing with transition. I suspected it has been a fuel supply issue. I have cleaned my tank, replaced fuel pump, bypassed my regulator, replaced fuel lines, replaced fuel filters. The pilot adjustment(idle) screws are pretty new and I can not find any issues with them. The carbs have been off and cleaned several times. The float adjustment has been checked and adjusted per Mikuni manual. I examined the needle/seat assembly and they look new, which they are pretty much since I bought them. Checked sync of carbs. I have watched the engine die and the pressure gauge shows 3.5 psi , so I think the supply is okay to that point. So would an issue with one cylinder kill the whole motor? If I had an issue with an idle jet with just one hole do this, or more likely a whole carb? I have the original needle/seat assemblies which I think I will swap back in to see if that makes a difference. I DO know that I am missing the accelerator check valve balls, which I got today(via Amazon, pack of 100-anyone need some-LOL) They got lost during one of the carb cleaning processes here lately. Float adjustment. So I have always done the inverted lid and measuring distance between top of float and lid at 12.5mm. The manual also gives you a height for the fuel in the bowl-24mm. It's not very user friendly since the measurement is from the center line of the butterflies upward, so you have to do some math to a get a number to measure from the top of the carb. When I did the math and measures the fuel height was off by 4-5mm-WOW. Can that even be right? I like this method better because that's actually what's in the bowl. I went with it and increased the fuel height and the car ran alright and seemed better in transition, but nothing to do with idle, still dies and idles rough. Curious if anyone else has gone down this route with fuel height adjustment ? I'll take some pics and get back with everyone

-

Cool!

-

I'd say if the cam is installed correctly it is NOT causing your idling issue alone. I can idle at 10 as well as 20 with not much change of idle. 10 thou off the head will not change valve timing enough to cause issues as you describe. Most cam profiles have a bit of advance machined in them just so they can be installed 'straight up'