-

Posts

2366 -

Joined

-

Last visited

-

Days Won

27

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by madkaw

-

Wiring Products.com

-

Might check out my MS3 install thread. The fuseblocks I am using are nice

-

Jesh- are you running a big block- lol

-

You can fix that with 3.90 gears!

-

Your problem is that you only have 1 pipe- you need double your pleasure with duals!

-

Left key on overnight. What did I burn up?

madkaw replied to BitchinZ's topic in S30 Series - 240z, 260z, 280z

LOL -

Well I'm not going to start a new thread since this issue has been discussed many times already. What I was looking for was stock pinion angles of operation for the s-30. I'm looking for exact numbers from your stock machine which includes down angle of trans, angle of DS, angle of pinion. My case of vibration is at 75mph approx. I WAS running the RT mount with GM insulator, but I have gone back to stock diff mount and using thr Rt to sandwich things-so-i should be in stock location at that end. The other end is my BWT-5 which has a mount bracket modified to fit my s-30. I think my trans is hanging to low, but would like to hear what operating angle is on a stock Nissan trans in the right chassis to compare with mine. I have been reading site after site on pinion angles and realized that my earlier calculations were not right. I am revisiting this issue, but knowing what Nissan did with the short DS operating angles would help clue me in. Obviously by all the threads I have been reviewing there has been numerous issues with getting this right---probably because of our very short shaft.

-

-

Let me finalize my design complete with wires before I try and sell anything. What you see here is my 3rd version already. Next will be deciding how and where I am going to run my harness(s) thru the firewall. What have some of you guys done?

-

Revived from the dead. I did get them to lighten my flywheel and haven't had any issues with it.

-

I have enough to make at least 3 or 4 more, but it's nothing special at all. Just 1.5" square aluminum notched with a hole saw to allow the round coil to sit flat. The bitch has been getting them situated that I can run the spark wires. This might not be my last version before it's all over. I need to get some stock wires from the JY and see how it goes. It would be nice to just order off the shelf than to make custom sets.

-

-

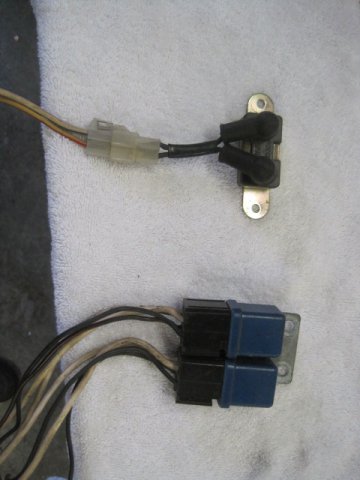

Well I haven't done much lately except for fixing squeaky urethane bushings. I did manage to finish up a prototype(sounds official) for my D585 bracket. This is pretty much a finished product, but might need some tweaking once I install spark wires. It was tougher than I thought trying to find room for all this; plus the fact that Delco couldn't have made these coils anymore unsymetrical in shape. I didn't want to reroute my heater hose and it will run under the bracket. The bracket attaches with the 2 bolts for the heater hose. I plan on using studs for mounting and it will be easier to utilize the block for grounding spots ,since there are so few. I bought a complete set of coils and diced and spliced the harness to make a six banger set-up.The connectors just clear all obstacles. The spark wires might be custom or stock. The stock wires might work by just looping the extra length of wire-if you can picture that. MS power; I have kept an old 82zxt harness that was in amazing condition and I have been canning parts from it. I have pictured what i think is the main starting circuit relays or the main relays off of the zxt. The fuse terminal block with the two leads I will use in line from the battery to the main relay. I'm betting it's a 60 amp for the zxt. The two relays mounted together should be perfect for the main and the fuel relay. The battery power will come from a 10 guage wire from the + battery. I will use another ganged fuse block like the one pictured on the inner fender which will be powered off the main relay. That will be dedicated for the MS. The ganged fuse block that is already installed will be just for accessories since it is powered straight off the alternator. Question regarding ignition input. I stare at the schematic that was supplied by DIY and I am having trouble interpreting how the ignition should tie in. They show power parallel to the battery +. Are they just implying that you need a hot wire from your ignition for the relay? I might be over thinking this.

-

WOW-that's bad! You probably oughta just sell it while your ahead.

-

Squeaking urethane bushings

madkaw replied to madkaw's topic in Brakes, Wheels, Suspension and Chassis

New bushings arrived and installed. New urethane bushings no squeaky! This time I ran the suspension threw its travel to see how freely the bushing were- and they worked smoothly. -

Could you not just tap into the Cannon "runner " that's there now? In the center would give you a good signal.

- 11 replies

-

Utter refusal to run at reasonable AFR's, noise problems

madkaw replied to Xnke's topic in MegaSquirt

If you blew a HG and ANY coolant got to the O2 sensor it's done. -

What a cool idea:) http://forums.hybridz.org/topic/96528-cai-for-triple-mikunis/?hl=%2Btriple+%2Bmikuni I would have done it different though for the turbo app. Keep up the work!!

-

New Cam and Rockers - odd looking at 500+ miles

madkaw replied to inline6's topic in Nissan L6 Forum

http://www.classiczcars.com/forums/engine-drivetrain-s30/23392-cam-oiling-investigation.html -

I think everyone has to check their rockers for being parallel. My rockers were supposedly new with my Schneider cam kit, but my wear shows an unparrallel condition-and they were.

-

Nice to see a happy cam story !

-

New Cam and Rockers - odd looking at 500+ miles

madkaw replied to inline6's topic in Nissan L6 Forum

I think my drill turns at 3800 rpm- how much do you need to see oil coming from the lobes OR spray bar. That looks like a sign of No oil. I would have pop canned a valve cover to watch it while engine was running. I would have done the drill to just prime everything. Not trying to rub anything I dude, because I know how frustrating this is got to be.