-

Posts

2366 -

Joined

-

Last visited

-

Days Won

27

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by madkaw

-

I thought I would give this a shot anyways before I try ebay or JY. Just need 2

-

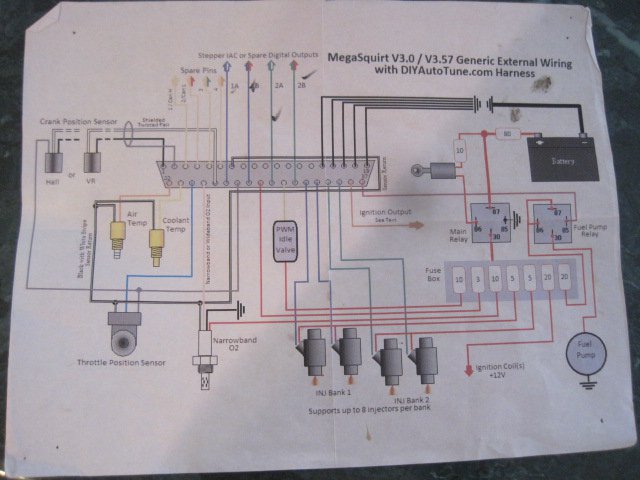

Am I missing it or is there a color code key for the ms3x harness. It's a bitch reading the spark wires. Sam-it seems the supplied schematic is easier to understand when reading instructions-especially when MS specifies grounding through the MS. I understand your point though.

-

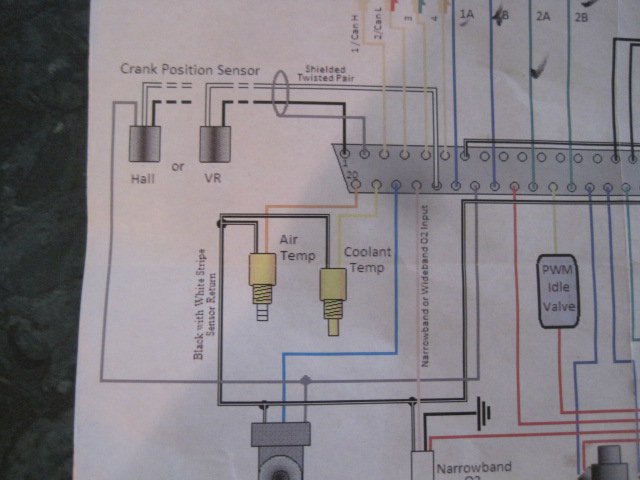

Here's why there is some confusion for me with the ground issue. I have attached the schematics that were supplied with my ms3x. They differ from the schematics available on line-especially sensor ground. Sometimes when I am posting I am not at home and I am referencing the on line stuff with my questions. I think the supplied schematic is better and easier to understand. I am glad to know that I also had the sensor ground pulled and seperated already, so I don't need to repull wires!!!

-

Thanks for your input guys. It seems that with a lot discussions on the forums( not just MS, any performance upgrade) is subject to the subjective. One guy says it didn't work that way or won't work that way because it didn't work for him. Then you see pics of a freaking birds nest they call wiring. I am just trying to nail down what MS wants looking at the manual. As far as grounding in this discussion , I think MS could have done a better job with the manual. You have to jump around a bit to find answers. Thanks again I hope this helps for future installs

-

Sam, Now I remember reading this before- thanks. Reading that tells me to find that 7 pin ground and ground my sensors with it . I think I attached the 7 pin with the rest of the black wires to the block.

-

Okay, so you are saying that though there is a dedicated ground wire on the ms3 plug for the sensors---internally on the PCB board they are all grounded in the same place? So I re read the manual. As you said they state that all grounds basically go to the same place. So is MS wanting you to connect all the sensors together with one ground wire versus each sensor ground running to a ground seperately ? I don't know why this should be confusing , but I want to get this right. I believe that I forgot to seperate that ground sensor wire from the rest anyway and grounded it to the engine.

-

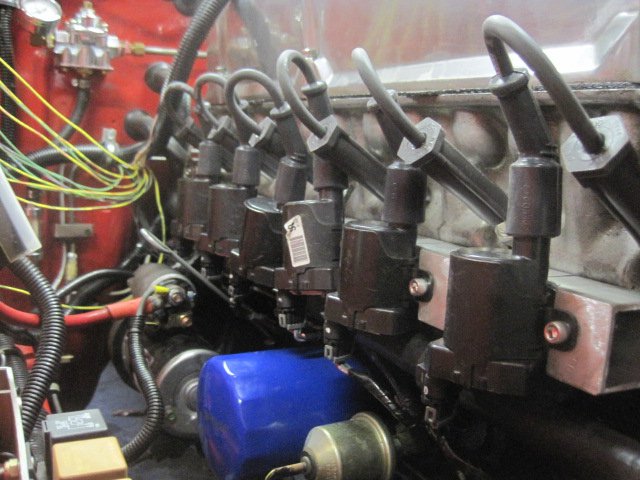

The bar sits on the raised bosses on the side of the block. The bosses are clean metal now and I did use dielectric grease between the block and the copper . I even chased the threads on the bolts for the block so that it was a clean connection. All the reading I've done on this MS stuff has made me over cautious about grounds. Thanks for the answers, now I can finish up these coils !! I drilled extra holes on the copper bar for additional grounds, looks like I'll need them

-

Fatigue or just BAD FABRICATION WORK?

madkaw replied to New-to-240z's topic in Fabrication / Welding

Any reason you haven't named the shop? -

Well as you can see from the pics , my coil wiring is right by my engine grounds. I seperated all my sensor wires away from all my other wiring. There is only one power ground running from the LS1 wire harness and one signal ground. So I can ground both of them at the block? The megamanual shows the signal ground to the ms3 and the earth to the 3x- whatever that means.

-

Signal ground for coil wiring ms3? I know where earth ground should go, but not sure where the brown signal ground wire goes. I'll keep searching

-

Fatigue or just BAD FABRICATION WORK?

madkaw replied to New-to-240z's topic in Fabrication / Welding

Not pretty or effective. Looks like flux core welding -

Not doing EDIS- MS3x allows to dial in on any trigger wheel. Going with a Cherry Hall sensor and going COP

-

Glad to hear you are still Zing!! We miss the Z expertise on the site, but glad has been good for you. I'm doing the same with my flywheel(though not professionally CNC'd) and my Megasquirt install. Glad to hear it works well. Not up and running, but it seemed like a great solution to the trigger wheel for me.

-

How are going to bolt that to the carbs? That base plate would have to be modified greatly or you will have to make something else. Even if you got the base to bolt to the webers, you might not have enough room for the plenum. The HKS type 2 plenum actually flowed well. The TMW box can't be pressurized - even at 400$$$$

-

"Cobbled together valve cover" OUCH!

-

http://forums.hybridz.org/topic/104821-nissan-cai-for-triple-mikunis/?hl=%2Bnissan+%2Bcai Try something like this

-

What year is your engine? An early e-88 or e-31 rebuilt would give you good power. Just bolting on the p90 would not be beneficial unless you shaved it down a lot and other work that will cost $$$

-

Well an outside temp of 5 degrees and snow on the ground should kep this project rolling-LOL I finished up my grounding busbar and hooked up all ground wires that MS said needed to go directly to the block. I basically removed any paint and sanded down the bosses on the block so the copper bar seats against the bare metal of the block. My thinking is this will provide a solid ground connection with lot's of area contact. My coil bracket basically mounts right on top of the grounding strap/bar and sandwiches it against the block firmly. The heater hose is attached to my coil bracket. It is tight, but everything fits and I can still get the oil dipstick out. The wiring should be mostly out of sight and out of the way. It seems everytime you get into one of these ventures you realize that every mm of room counts. Now to wire up them coils!!

-

WTB 240z License Plate Light in nice condition

madkaw replied to RB26powered74zcar's topic in Parts Wanted

Gotcha -

WTB 240z License Plate Light in nice condition

madkaw replied to RB26powered74zcar's topic in Parts Wanted

The ones I have are for 70-73, you need 74? -

WTB 240z License Plate Light in nice condition

madkaw replied to RB26powered74zcar's topic in Parts Wanted

I think I have one. When I get home I will check. You need a complete assembly- correct? -

Probably won't chop anything off permantely. I will just keep them out of the way. I am just trying to make sure I pulled enough thru the firewall for now. I read where you can use the extra injector wires as drivers or for an extra set of injectors, but I thought pulling all of the medium current outputs from the 3X loom would cover any additional soleniods . As far as the 3x loom, it looks like I am going to run about everything except the Launch in,n2O,tablesw, PT4. I might not run all the 'analogue in' either. I might have one available for fuel pressure. I have also decided to try and come up with something using a hall sensor to make a cam sensor. Now that I have researched what it takes to have a signal for sequential, I might as well take a stab at it. Thinking of creating something using the dizzy drive. Maybe along the lines of the Jeep 4.0 cam sensor. appreciate the input

-

Questions regarding wire eliminations; I am probably going with PWM idle control and PWM control for additional devices(electric fan, etc..) It seems that the 3X plug should cover about anything i want to run. It doesn't seem like I am using the main plug for much more then powering the MS and sensors. At this rate I am eliminating 14 wires from the main plug-but don't want to short myself. What reason would I need any of the digital outputs or spare pins on the main plug?

-

Your question is kind of confusing. So you have a p90 head you want to put on a L24 block? I'm pretty sure the p90 is drilled for using the carb intakes, but someone else might chime in. Meanwhile-please clarify what you are doing