-

Posts

2483 -

Joined

-

Last visited

-

Days Won

24

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Leon

-

Coilover Conversion Data sheet

Leon replied to tamo3's topic in Brakes, Wheels, Suspension and Chassis

Great compilation, Takashi! -

Nice Mike! Looks like a great LeMons/Chumpcar entry.

-

I think this is the type of curiosity and thinking that we welcome at HybridZ. Looks good to me, at a glance. I would call those "torques" and not "moments", but that's nitpicking. Luckily, designing brakes isn't as complex as engines or suspensions. To dial in the balance mathematically, you need to now the friction force between the tires and road, vehicle weight, wheelbase, CG height and CG longitudinal placement. With that said, our car is already designed so jumping in and finding optimal balance empirically makes more sense, especially given the lack of info on CG locations and tire data. Brake force needed can then be back-calculated to see how much pedal force is needed, knowing tire, rotor, and piston sizes, and pedal lever ratio. The Brake Handbook by Fred Puhn is cheap and a good read, if you're interested.

-

Correct, piston area affects braking force, not pad surface area. This is physics 101: F=μN. Brake force depends on the coefficient of friction between the pad and rotor (μ), the amount of force the pad exerts on the rotor (normal force, N), and rotor diameter at which the force is exerted. It's the force that matters. Two small pistons don't necessarily exert more force than one big one, it's the combined area that matters. I don't know the piston areas off the top of my head.

-

Dyno time!

- 67 replies

-

- EDISMegajolt

- Ignition

-

(and 1 more)

Tagged with:

-

I'm pretty sure he did, but I didn't check (nor know the differences between the two off-hand).

-

Nice job!

-

Yes, they were both maxed out.

-

HBZ Rules sirbinly, sorry that such a mess has been made of your WTB thread...

-

Rear Wheel Stub Axle Play - Help Needed

Leon replied to Wheeler's topic in Brakes, Wheels, Suspension and Chassis

FWIW, the 260Z prefix was "RLS30". R means L26, H means L24 or L28, depending on model. -

Unless the car is tuned properly for the catalyst (controlling its temperature which is AFR, CR, Timing and cam dependent), the converter will degrade in a matter of months. As for the other question, see above.

-

Not around here. I bought rust free rollers for <$1k and drivers for ~$3k. Come to CA and buy it here, then ship it back. All you really need to do to make it look like a 240Z to anyone besides knowledgeable Z enthusiasts is change the bumpers. A decent set will run $300-400 plus you'll need some $40 brackets (or make them yourself). BTW, there is no need to have 18 arrows and 53 periods at the end of a sentence.

-

There's a good chance they're SAE threads, as T-B alludes to.

-

I sent the P90 cam to Isky for a custom regrind today. I also heeded Steve's advice and took a crank pulley along with a couple of flywheels to the shop for balancing. I'm hoping I get my bottom end stuff back by next Friday, but I'm not sure what the timeline on the cam will be.

-

I got some Duplicolor engine paint at O'Reilly, Pontiac DE1610. It's about the closest you get to the stock color. I also got some self-etching primer for the block, as recommended by my engine guy. The WD will be removed and I will be cleaning everything obsessively, that's for sure. Thanks Jim!

-

Both the pulley and flywheel should be balanced all by themselves, as this is an internally balanced engine. The reason I'm not as concerned about the pulley is because it is a smaller-diameter part compared to the flywheel and "should" be balanced as long as it's in good shape. Plus, I may buy a new pulley in the near future. The flywheel is an old 10lb Tilton unit and I'd like to make sure that it's in good shape. Plus, I'd have to figure out which pulley I want to use from my collection!

-

Engine is back from the shop! Block was bored out .020" and decked .004". It's a bit wet from a generous dose of WD40. The head was shaved and got a 3-angle seat cut. Rods and pistons were balanced, pistons mounted (ITM flat tops), and rod bolts pressed in. Today, I finally took my crank to a shop close to work who will polish it and send it off to be checked for balance. I'm including the flywheel with it to be balanced as well. Figured the crank pulley should be in balance, but I'm thinking of taking it in as well.

-

Guys, before we delve further into this, I helped mistah mofro work on his car last week... Comp came out OK, but oil is white and milky. It could very well be from condensation but needs to be changed ASAP. Then, I confirmed TDC as best as I could (plugs out, looking with a flashlight into #1 plug hole while Alex turned the engine). We marked the pulley at TDC and then checked timing. Timing at idle is somewhere in the range of 0*-5* retarded with both distributor adjustment screws maxed out. This is why the car has no power and backfires through the carbs (and a nice big one from the tailpipe). We moved the plugs over by one spot but that resulted in so much advance that the car wouldn't start. I think the carbs were then tuned very rich to compensate (also carbs are out of sync but proper timing needs to be established first). I told Alex that he needs to re-orient the oil pump spindle per factory instructions, so hopefully that is done soon. The engine was swapped out of another car that was apparently running well and the only thing that was changed was the distributor. This leads me to think that there are minute differences in adjustment screw locations which in turn doesn't let the ZX unit advance as far as whatever distributor that was in there.

-

I'm betting it's fuel/carb related. Sounds like the culprit is the emulsion tubes, since it seems to be a common characteristic of DCOEs with F-series tubes to lean out at higher RPM.

- 67 replies

-

- EDISMegajolt

- Ignition

-

(and 1 more)

Tagged with:

-

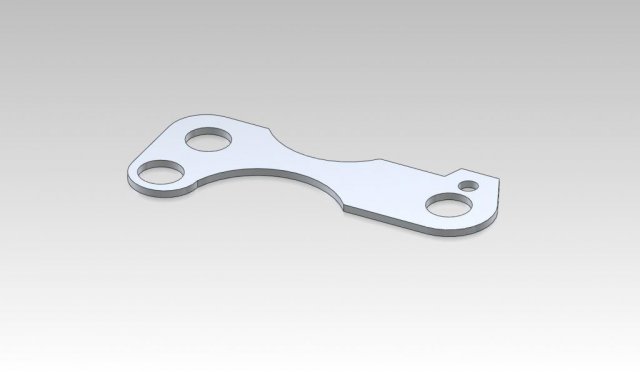

Got some 7075-T6 shim stock today and modeled up the shims... I'll be cutting them on a CNC wire EDM for accuracy, plus there will be no burrs for me to clean up. Just perfectly sharp corners.

-

Have you tried smaller air jets? It could either be a progression hole problem or a main circuit tip-in problem (solved by the right combo of e-tube and air jet).

-

Weber jets??All who live for their triples please read this

Leon replied to datfreak's topic in Nissan L6 Forum

Steve, buy a real flowmeter, the Unisyn is junk (as you can see). I gave my last one away. Get an STE SK syncrometer and it will make your life a lot easier. -

I measured the head with some vernier calipers before I took it in and the head seemed to be stock thickness (~108mm). It was in great shape and didn't look like it had been messed with. I plan to remeasure chamber volume just to be sure. I'll also measure head thickness to see how much was taken off. A copper gasket sounds nice but the $135 might be hard to swallow right now! I still need to decide on fuel line routing and order AN lines and fittings which will be a pretty big expense. I'll keep the copper gaskets in mind, Jim. Couple more things to cross off the list: - Regrind rockers (shipped to Delta last week) - sourcing 2mm/0.080" cam tower shims (ordered .080" 7075 shim stock yesterday ) - sourcing longer valves (SI has great prices) - low profile valve stem seals (FEL-PRO SS72686 bought on ebay) - figuring out my cam and springs, lash pads may need replacement (made cam sizing spreadsheet, still need to call Isky...) - Head gasket (will probably get Fel-Pro, maybe copper?) - Manifold studs (MSA) - Manifold gasket (turns out I have spares) - Valve spring shims (TBD) I'll also be going through boxes of parts this weekend and trying to inventory what I actually have.

-

I need info about Z racks for my 215 510...

Leon replied to ByStickel's topic in S30 Series - 240z, 260z, 280z

It's a manual rack-and-pinion setup, pretty much as direct as it gets. Everything else is hard to comment on because feel comes from the suspension setup and quickness depends on the length of your steering knuckles. The stock setup is pretty quick, but not lightning-quick like some modern power-assisted setups (which allow for a quicker steering ratio).