tube80z

Super Moderators-

Posts

1401 -

Joined

-

Last visited

-

Days Won

31

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by tube80z

-

Caliper Weights/Best rotor

tube80z replied to jing's topic in Brakes, Wheels, Suspension and Chassis

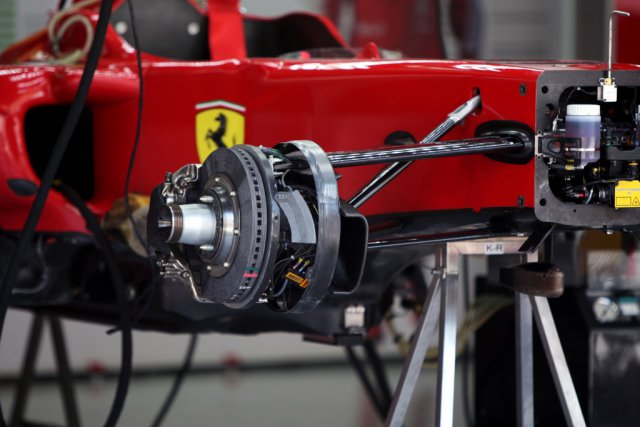

They are vented, attached is a pic of the Ferrari front brakes from Malaysia this year. The rotor floats on a hat, which floats to the hub on a splined interface. Cary -

Caliper Weights/Best rotor

tube80z replied to jing's topic in Brakes, Wheels, Suspension and Chassis

So you're the responsible party for Marc?! We need to have a talk out behind the shed On my autox car I use the lightweight rotors with gas slots. Not as light as the cross drilled rotors but they last a lot longer. On a friends EP car rotors were lasting one qualifying and race before they broke and he had a lot of ducting. Switching to cryogenic treated rotors solved the issue. He routinely sees 1200 degree temps. Cary -

Installing GC Camber Plates using a Template

tube80z replied to Zzeal's topic in Brakes, Wheels, Suspension and Chassis

Nice work! -

No, you're not alone. Saw that one myself and thought it was a nice looking car. I think I'm watching the older episodes on A&E or something like that. Still lots of catching up to do. Cary

-

It's hard to say for sure what you'll need to do for the Avons. You'll need to find someone with first hand knowledge of their care and feeding or do a lot of testing. On a friends EP car it took more spring to turn the GYs on and once that was done the car decimated the track record. Tire temps had been in the 105 to 115 range. Now they are about 180, which is still low according to the GY engineer. All I can say is your LA numbers still look low but that may be track related. On slicks I'd expect to see low 1.4s when everything is sorted and working well. I know you're no longer using the FA tires but your setup wasn't correct for them to work properly. FA tires are designed to be used as half your suspension travel. Until you do that they don't seem to work very well. And I know they are designed for a light car (1380 lbs) but you have to remember those can make 3000 lbs of downforce.

-

Here's what's on the site. Send original register receipt dated between May 18, 2009 – August 31, 2009 showing proof of purchase of five (5) one-quart bottles or one (1) five-quart jug of Mobil 1 Advanced Fuel Economy motor oil and completed offer form to: 2009 AFE for Alliance Rebate Offer P.O. Box 1103 Grand Rapids, Minnesota 55745-1103 Offer conditions: All rebate requests must be received by September 17, 2009. Limit two (2) rebates per person and per household. Rebates can be combined in one envelope. Allow approximately 6-8 weeks for delivery following receipt of all required documentation.

-

Finding out Spring Rates?

tube80z replied to jc052685's topic in Brakes, Wheels, Suspension and Chassis

Unless your springs are marked you will need to measure them directly. One approach often used is to put the spring on a bathroom scale and press using a drill press. You push down a set mount (usually an inch) and take a reading. The other way is to measure the coils and do math -- but who likes math Cary -

I found this Mobil 1 rebate offer and thought people might be interested. Wal-mart has the five-quart jugs for $22, which after the rebate will be only $12 each. Details at https://www.mobiloil.com/USA-English/MotorOil/Promotions/Promotions.aspx

-

If your pressure rise is equal front to rear then your setup is probably ok. Generally if the temps are out of whack the pressure rise will be too. But like John said sometimes one end will cool quicker so you need more data. Don't get too hung up on LA numbers. Your track may not have the same level of grip and you'll see it vary throughout the day/weekend. But if everythings working those numbers are what I've seen on an EP car, which isn't too far from where you can take your car.

-

Cameron, it's kind of hard to tell from what you've written how much the cool down lap lowered your temps. Do you have a hot pit you can come into when you're running? That would be a little better. But generally I'd expect to see temps near 200s for those tires. From my experience you're barely getting them to work, which is why the LA number is so low, unless the track just doesn't have that much grip. If the tires are working I'd expect to see numbers in the 1.4 to 1.5 range. It also seems you're working the rears a little too much. What is the pressure rise? A friends very fast EP car has very similar temps front to rear. At least at this point it sounds like the rear is being worked pretty hard. And as Jon mentions you need to up the springs to build temp in the tires. Talk to the trackside tire engineers and they will tell you the same thing. And if you have dead spots in shocks (from your other thread) that may not help get temp into the tires. Only trick I know is to try and raise the instant centers in your suspension. That should build more heat.

-

My strut tower brace design

tube80z replied to h4nsm0l3m4n's topic in Brakes, Wheels, Suspension and Chassis

If you don't make it double shear then you should change the strut bar mount to a clevice. This will make it stiffer than a rod end. -

Then your car isn't that stiff and it will limit what you can do with suspension. You can work around it but it will cause issues given the amount of force your car can generate. The springs aren't really the problem with compliance. It sounds like you have shocks that are not matched for higher rate springs if you have skipping. A number of us have lighter cars with stiffer springs and don't have these issues. A friend of mind used to run a LS1 car (2500 pounds) on 400/450 springs and it worked really well. Probably could have run a little stiffer. Since you want to drive your car to the event one trick I could think of is to stack coils, say a 200/250 rate and a 500 or so. You'd need a plate on top of the smaller rate coil that allowed you to compress it flat. When you get to the track and remove your wheels to change your brake pads you can clamp down the lower rate spring and have the benefits of stiffer springs. This probably means you need some adjustable shocks you can back down for your trip to and fro. (versus a single set setup correctly). This is all something that can be done fairly easy. I'm assuming you've already put the suspension on heims/monoballs. If not that would be a nother good option to help make it more controllable. These two areas will probably make the biggest change assuming you can't remove a lot of weight. What I've seen 8 out of ten times in the past is that you're car is too soft and the excessive roll causes the wear. In the other cases compliance can cause dynamic alignment changes that cause it. We're assuming you don't have some alignment issues on the car. The cheapest method to go quicker is a stop watch, tire guage, pyrometer, and a camera. You're tires will tell you how how the chassis is working, the stop watch if you faster, and the camera can stop time when the car is loaded in a corner. You'll learn a lot by analyzing those photos. We make more changes based on photographic evidence than anything else when we're trying to get a new car to work. Most of the people I play with don't have the budget for data acquisition and enough sensors to gain any real insight (chassis tuning requires wheel position). Cary

-

Okay, so no trailer. I'd opt out of any hillclimbs then as the chance to wreck your car is higher there than just about anywhere. I can't recall if your car has a cage or not. While not sexy or go fast good safety gear would be essential just in case. My self I found that doing work to make the driver more comfortable was almost as important as things I could do to the car. Your car is probably too soft. It seems to me that you're aiming for a car very similar to an EP car with a V8. That means springs from about .8 to 1.0 of corner weight (assuming frequencies in the high 2s to maybe 3 Hz range). That should get you into the ballpark. You've already mentioned brake pads. Do as Jon said and take a set for changing at the track. Then figure out the next things to tackle (I'd work on suspension first). You'll probably find as much time in learning to set the car up for conditions and the track your at than you will in new developments. Once you've got this nailed then you may want to look at trying to see what you can do to get rid of lift/make some downforce. This will cause all the suspension stuff to change again and brakes may become an issue again. And then maybe think of more power. Look at first principles, those are newton's three laws and there variations. And look for low hanging fruit, like seeing what weight can be shed. Then of what's left what can be moved lower in the car (mass and Cg). Even simple things like lowering your seat can reduce the Cg of the car. Increasing track width (more grip), more tire, etc. It will be a never ending list that once you touch something new you get to revisit all that you did. Feel free to ask specifics. I'm sure there's a lot of good advice to be had on this list. Cary

-

Where to get quality lug nuts?

tube80z replied to heavy85's topic in Brakes, Wheels, Suspension and Chassis

I'm using standard diamond nuts. If you're wheels allow it I'd try any of the quality circle track parts. I've had people "help" me and cross thread the nuts and start to drive them on with an impact. And these can be backed off only screwing up the nut so far. I life the studs and the nuts every three years and that may help too. I'm sorta anal that way. Cary -

Where to get quality lug nuts?

tube80z replied to heavy85's topic in Brakes, Wheels, Suspension and Chassis

Are you using a anti-seize or lubricant on your studs? I've never had this happen to me but I make sure they are not dry. I've seen many people have this problem when they don't. Good studs and soft nuts are best. If the nut gets cross threaded you zip it off and throw on another. That's standard race car practice. Cary -

I personally haven't made a lot of progress but was headed down the path you'll find described on the V8 RX7 forum. That is to take the stock Ford CV halfshafts and cut down the inside and weld on a flange and use the bolt-in CV conversions available for the Z car. This takes care of the outer hub issues a lot of people are worried about. Cary

-

Give ZTherapy a call. They did a little research on E85 and SUs. From memory everything other than the fuel lines had no real issues. You're going to need bigger nozzles and new float to carb lines anyway. Cary

-

I think you forgot track days in your analysis. Because if all you really want to do is autox I'd recommend a richmond dog-ring 2-speed. Mucho lighter. With the v8 you're looking at running in mostly a single gear. What you'll need to do is have a couple of rear gears to pick speed ranges that work best (one gear to 70/75 MPH). From my experience this is always faster than shifting and much easier to drive. Things happen very quickly when you prep to this level. Backs are broken etc. I can see having more gears for track days, which I think you want to do. I'm going with a Muncie or a ex-NASCAR dog ring 4-speed and will change rear gears. But with no overdrive you'll need a steep rear end to make 150 or so. Cary

-

Weld in Camber plates vs adj lower control arms

tube80z replied to rags's topic in Brakes, Wheels, Suspension and Chassis

Flip the plate with the spherical and get it out as far as you can. That's what a lot of us have to do in the rear when we lower the cars a lot. -

Search for hemipanter on google and you'll find the designers home page. You can buy a book on how to create your own from him. I've been tempted just because I seem to collect books on one off racing cars.

-

Weld in Camber plates vs adj lower control arms

tube80z replied to rags's topic in Brakes, Wheels, Suspension and Chassis

The template shows what needs to be cut out. If you place the plate on the strut tower you will see where you need mounting holes and what needs to get cut out. The plate is supposed to be mounted under the metal on the top of the strut, not on top. And for enlarging the center hole I've found that aviation snips work as well as anything. And if you want a template I'd call GC and pester them. They used to hide things on their web site you could download. You don't really need this but it was nice to have. Cary -

Weld in Camber plates vs adj lower control arms

tube80z replied to rags's topic in Brakes, Wheels, Suspension and Chassis

They bolt in but you'll need to cut the strut towers per their template for them to properly fit. Cary