NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

No battery light 94 Z32 N/A

NewZed replied to Edgecrusher's topic in Trouble Shooting / General Engine

How do you know it's erratic? Doesn't look like you're measuring anything. You would have found that loose connection. -

It is page 131, illustrated on 132, good memory. Thought you were talking about the hole at the top of the quill. Seems like it could be machined and a bushing inserted. Covers were probably cheaper and easier to find back when he wrote that book. You might also find a Redi-Sleeve or Speedi-Sleeve that fits the shaft. I'm not a machinist or engine builder though. http://www.timken.com/en-us/products/seals/industrial/products/Pages/redisleeves.aspx http://www.skf.com/us/products/seals/industrial-seals/power-transmission-seals/wear-sleeves/skf-speedi-sleeve/index.html

-

Where is this specification? Can't seem to find any reference in the FSM chapters.

-

Wide-deep or wide-wide? One picture is worth a thousand saggys.

-

No battery light 94 Z32 N/A

NewZed replied to Edgecrusher's topic in Trouble Shooting / General Engine

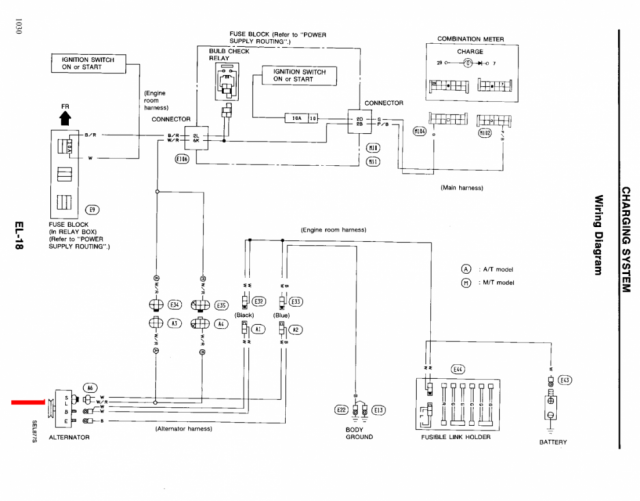

You might be on the right track. No power to the L terminal usually means no charging will happen. You can check for power at the plugs, alternator or instrument panel, with a meter or test light. -

Only with a 1978 EFI harness. 1976 uses a switch n the AFM. It's all described in the Engine Fuel chapter of the FSM. Lots of important other stuff in there too. Don't overlook that air flow moves the AFM vane that allows the switch to close. And that the crankcase is connected to the intake system through the PCV. All air must pass through the AFM. The crankcase, from dip stick tube to PCV to filler cap has to be sealed. If you're not familiar with the 280Z EFI, there are many other little things to pay attention to. Read that chapter.

-

So, engine modification support, not really swap support? VH, VG, VQ,1UZ, etc. (don't forget VK) is a lot of platforms. Good luck. You can get a feel by counting the posts in those sub forums. Quantity is what the aftermarket looks for.

-

Very windy. What do you mean by "support" anyway? Aftermarket for all of the swaps is somewhat spotty and sporadic. The volume is too low. It's more of a DIY thing, using Megasquirt or Nistune, and cutting, bolting and welding, than plug and play kits. http://forums.hybridz.org/forum/17-6-cylinder-z-forums/ http://forums.hybridz.org/forum/46-other-v8z-tech-board/

-

My 76 has the nipple style. Yours may have been modified. Modify it back to what it was. Or just unscrew the senders and swap them. Use a wrench on the nut underneath, don't try to turn the body, It might twist and destroy the guts inside. And a 78 oil pressure sender also has a switch inside. Two blades, not one nipple.

-

The four speeds will work also, if you're doing a 71C swap. Reverse switch hole might need drilling.

-

Distributor/Oil Pump Shaft Timing

NewZed replied to Bigbrowndog's topic in Trouble Shooting / General Engine

Does it start and not run? Or not start and not run? Or not spark and not run? There a different mounts for different distributors. The wrong one will give the wrong range. With points it's pretty easy to see when they are about to open. That will be when the spark happens. You can get a rough idea of timing by timing by looking at that. Turn the distributor until the points are about to open and see where the timing mark is. Sounds like your ignition circuit might be shorted. "Trying to start" could mean standing there with the key on, or cranking the engine for extended periods of time. You could measure voltage with the key on and compare it to key off. If no current is flowing, they'll be the same. If the circuit is shorted there will be a voltage drop. Could be that your points just need adjustment. Not opening. -

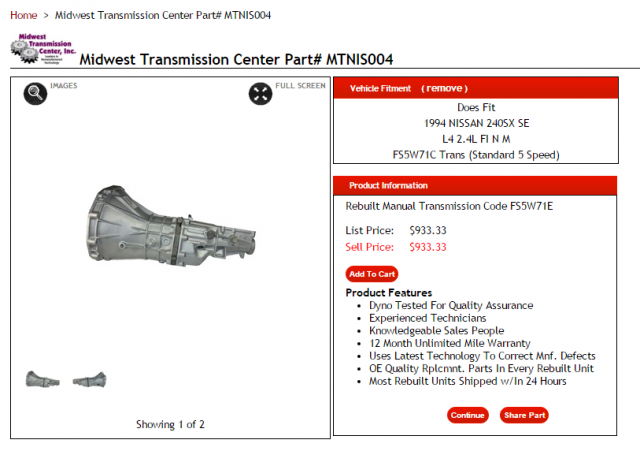

I would measure length first. Overall, and each case, front and back. The smaller cars and trucks seem to come with shorter tail shaft housings. And you can see the countershaft bearing by popping off the front cover, no need to split the cases. Here's another example of ID code. "E" and "C". http://www.midwesttrans.com/webapp/catalog.jsp Good luck, have fun.

-

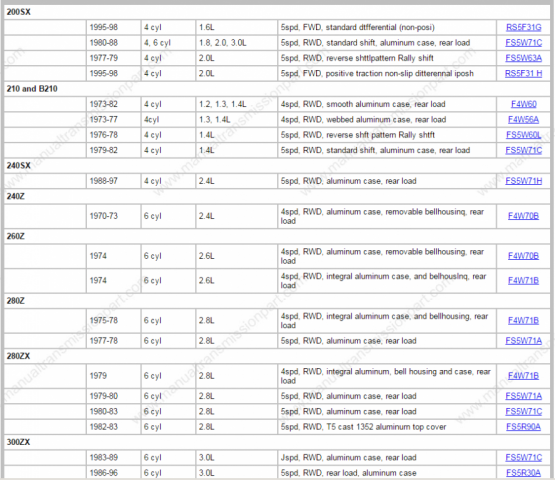

Here's an example - http://www.manualtransmissionpart.com/NISSAN-Cars-ID-Make-Model.html The parts places are all screwed up. Don't use them for any ID by number.

-

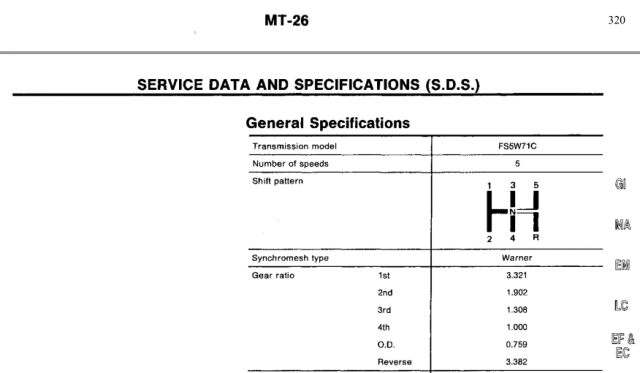

Sorry, I miswrote. Nissan still calls the transmission the 71C even in 1994, for the 240SX, US market. It's when you buy parts that you'll find the other letters. It's messy. This is from the 1994 Service Manual.

-

There are lots of variations out there. Length of the tail shaft case, for instance. Yours doesn't look like either of the two 240SX units shown in the popular writeups (Nigel/Motortopia and Steve/zhome), which also don't look like each other. Better triple check.

-

I've never seen a good explanation of what the B or C means. Most call the later transmission the 71C because that's what Nissan calls it in the 300ZX Service Manual, when the VG30 was introduced. But there are many other letters used. Even the early 71C's had the same synchros and gear widths as the 71B's, so once you swapped bells you had essentially a 71B with a different shifter and set of gear ratios.. But, the countershaft bearing size was larger fro the 300ZX 71C, so that's one definite difference. The later US market 240Sx 5 speeds with the extra synchros and wider gears were actually either a 71H or 71J (can't remember which), not 71C.. So, in your case, you might still have a smaller countershaft bearing, and an unususal set of gear ratios, and either the same number of synchros or more. I would find a Service Manual for 1992 European 200SX and see what it shows. Nissan's casting marks and numbers haven't been very useful, at least on the early Z's.

-

Not clear if you're hoping this is the front case/bell housing or the gear set. Looks like you got a 71C gear set, that will need a 71B bell housing to work on an L6. The shifter is an easy clue, and the cross hatched bell. You can check the angle of the mounting holes also.

-

Isn't this edwin's thread? Confused.

-

Sent My N47 Head to The Machine Shop.....

NewZed replied to FrappNasty's topic in S30 Series - 240z, 260z, 280z

Check page 89, it describes the tap and turn procedure. Be careful on the torque values for the bolts, one of the books, either Monroe's or Honsowetz's, has a mistake. Your shop will probably get it all done right though, if they've worked on them before. -

Sent My N47 Head to The Machine Shop.....

NewZed replied to FrappNasty's topic in S30 Series - 240z, 260z, 280z

Most people call them cam towers. If he marked them they should go back on just fine. Search "cam tower alignment" and you'll probably find some threads about tapping on the towers while bolting them in place. The towers are the bearings. Interesting work you're having done since lash pads are hard to come by, along with new rocker arms. Plus the issues with cam break-in. Details on what parts he uses and how he sets them up would be worth posting. -

You need more info like brand (struts), and condition (everything).

-

Your Distrub is actually a Crank Angle Sensor (CAS). Are the injectors labeled ABCDEF for sequential injection? Seems like all that you're really showing is that some devices get 5V and some get 12V. Are the wire colors on your Distrub correct for the 198X turbo CAS, and coil wires correct for LS2 coils? Details like that would add some clarity. You need a Legend.

-

These threads came after the FAQt - http://forums.hybridz.org/topic/100094-cv-axle-discussion/page-3 http://forums.hybridz.org/topic/105514-m2-cv-adapter-for-z31t-cv-280z-stub-axle/

-

Megasquirt is open source, I believe. Some hot rodder/coder out there could probably figure out a way to drive two ignition types at once. One for the plugs and one for the 240Z tach. The "adapter" might just be a separate ignition coil that discharges to ground, dedicated to the tachometer. It would look like a plain old points ignition system to the tachometer. A person could even run a distributor just for the tachometer, if they had a crank trigger for the plugs. It would have no plug wires or coil wire. The coil discharge wire would be attached directly to ground. Actually, you wouldn't even need the cap, except to protect the points. You could build a smaller cap for that purpose. The distributor and its points would just be an RPM counter for the tach.