NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

The Hi 6 will be the new "ignitor".

-

You can make 1000 HP but can't find the size of a wheel stud? Reminds of a guy I knew who spent a lot of time bench-pressing to build a big chest, but had tiny bird legs. Here's something Google found with some words I remembered. http://forums.hybridz.org/topic/95937-78-datsun-280z-53-build/page-16 #308 and on

-

Need a little help with a short (I assume)

NewZed replied to 74Adam's topic in Ignition and Electrical

Here's a link to one with some color. Not perfect but easier to read. Looks like C6 feeds the gauges, which makes sense since my gauge lights died when the tail lights did. That was the clue. You might try unplugging sub-harnesses also. Unplug C6 and see if the tail lights work. Or take out all of the lights and see if C6 still blows the fuse. http://www.classiczcars.com/topic/42132-a-somewhat-color-wiring-diagram-for-1978-280zsenjoy/ -

Need a little help with a short (I assume)

NewZed replied to 74Adam's topic in Ignition and Electrical

But what happens if you leave them removed? I like to work from the simplest case, then make it more complicated until the answer shows. If there's no short with all of the lights removed, then you don't have to worry about all of the stuff between the power and the sockets. If the short still happens with the lights removed, you can still leave all of them out until you make the short go away. Start as simple as possible. You might even have a defective bulb with an internal short, or a short across its electrodes. It's possible. -

Need a little help with a short (I assume)

NewZed replied to 74Adam's topic in Ignition and Electrical

Pull all of your tail lights and see if the fuse still blows, or check for short to ground with a meter (save some fuses). Look inside the sockets to make sure they're not touching. I had a contact in a socket get hot enough to melt its way sideways to a short. The bulb contacts get old and oxidized, and the oxidation heats up. -

There's another one. But it sounds like you have a plan so carry on.

-

Sounds lean. I've had several old AFM's that run lean. The simple fix is to add a potentiometer in-line with the coolant temperature sensor wire and raise resistance to add fuel. But I also have had bad/clogged injectors, that ran lean. Vacuum leaks will also cause a lean condition. Could be any, all, or a combination of. On an EFI car that has sat for a while, it takes some time to go through all of the basics of fixing vacuum leaks, cleaning connectors, tuning up, etc. Download the 1975 FSM and read the entire Engine Fuel chapter, you'll understand a lot more, like how to properly check fuel pressure (and what the number should be). Also read Engine Electrical and you'll realize that you shouldn't have points, and that the second set is only used for a short time anyway. They're for emissions, not performance. http://www.nicoclub.com/FSM/280z/

-

You mean you twisted the tip of the shaft that extends down through the cover to the oil pump drive gear, and it had that much play? That doesn't sound good. Someone from the recent past found that their drive gear had moved on the shaft. Search around and you might find the thread.

-

260Z Build: Phase 1 - Suspension & brakes

NewZed replied to Bob_260's topic in S30 Series - 240z, 260z, 280z

I think that the scalloped hubs were used only on the very early 240Z's, not all 240Z's. The other early/late indicator might be the height of the rear strut towers. But, as you've found, the tube diameter is the best tell.- 25 replies

-

- Rota

- disc brakes

- (and 7 more)

-

Looks like there is a Ring-O. http://www.carpartsmanual.com/datsuns30/DatsunZIndex/Engine280Z/FuelTank/ToJul-76/tabid/1621/Default.aspx Courtesy shows it but low availability - http://www.courtesyparts.com/ring-o-p-265964.html

-

For curiosity only, not dispute, what are the signs of flex that you see? Stress cracks, wheel hop, shattering glass, ...? And do you know what is flexing? The cars are big, squarish tin cans so flex probably happens in multiple areas. If one area flexes its counterpart has to also. It's been discussed pretty heavily but always good to get a new view.

-

early 260z to zx distributor wiring

NewZed replied to Hypertek's topic in S30 Series - 240z, 260z, 280z

Is it really wired that way or you just think it is? You show constant power to the coil and ignition module, even with the key off. Makes no sense. Just use the factory wires at the ballast. Nice use of color in the drawing though, I can see why it's attractive. -

early 260z to zx distributor wiring

NewZed replied to Hypertek's topic in S30 Series - 240z, 260z, 280z

Nothing special about a 260. Open the link and read. You've already been pointed. The wires are already there, at the ballast resistor. -

early 260z to zx distributor wiring

NewZed replied to Hypertek's topic in S30 Series - 240z, 260z, 280z

There's some bad information in that thread. I stopped reading when I saw the thing about the aquarium valve on the vacuum advance hose. Kind of ingenious but the analysis of how the mechanism operates was incomplete. Here's a site with some ideas that seems to work well. You want power when the key is On, and at Start. Pretty sure if you wired it the way it's shown in that thread, the engine would not turn off with the key. It's basically "hotwired": http://atlanticz.ca/zclub/techtips/distributor/index.html -

260Z Build: Phase 1 - Suspension & brakes

NewZed replied to Bob_260's topic in S30 Series - 240z, 260z, 280z

Click More Reply Options. Then Choose File, then Attach This File. If it has sat for 30 years, the brake fluid has probably absorbed enough moisture to corrode both wheel cylinders, both calipers, and the master cylinder. If you're lucky the brake drums will come off so that you can work on the shoes and get to the wheel cylinder bolts. Should be fun.- 25 replies

-

- Rota

- disc brakes

- (and 7 more)

-

You mean the piece on the bottom, held on by the roll-pin? Looks like a 280Z piece, before they went to the plastic design around 280ZX time-frame. Wouldn't be surprised if they were the same. If you had dimensions it could be checked. I have some. For checking only, not for sale though.

-

I don't like to post in the FAQ threads but this seems like it might be appropriate. clarkspeed posted a link to a site, about shocks, but the site also had a pretty good description of the different differential options and how they behave. http://farnorthracing.com/tech_quaife.html (after 175 posts, maybe it's already in here...) clarkspeed's post - http://forums.hybridz.org/topic/69623-the-strut-thread-koni-illumina-tokico-carrera-bilstein-ground-control/page-23?do=findComment&comment=1135971

-

260Z Build: Phase 1 - Suspension & brakes

NewZed replied to Bob_260's topic in S30 Series - 240z, 260z, 280z

There are no verbs in your plan. Are you planning to drive the car while working on it or work on these things over a long time frame? You haven't mentioned what you plan to do with the car when it's done. An engine "upgrade" for drag-racing would not be the same as one for the street or autocross. Might be fun to just get it back to stock running condition before the final plan is set. I bought mine thinking I'd do a small-block chevy swap but found that the L6 is plenty of work and fun.- 25 replies

-

- Rota

- disc brakes

- (and 7 more)

-

Scale? 1 mm or 1 cm? Is it flat? Jagged edges? An ugly freehand Paint drawing might tell more.

-

Fuel gets mixed at the carburetors, so no cylinder should run leaner or richer than another with a single carburetor. Might have more or less charge, but the fuel/air ratio will be the same. Multiport EFI, on the other hand, can run leaner or richer, since the air flow can vary but each cylinder gets the same quantity of fuel.

-

You obviously haven't been stalking for long.

-

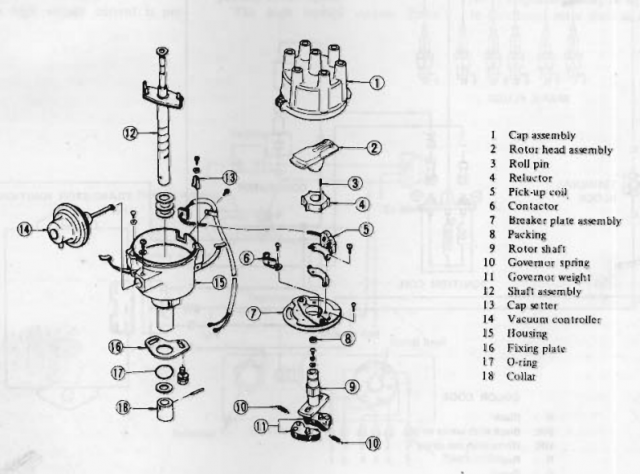

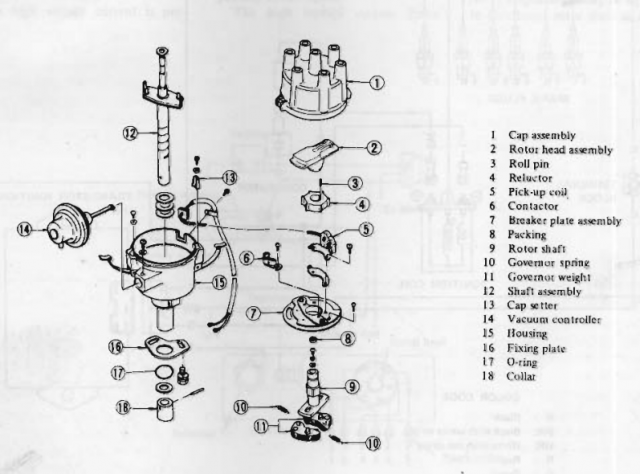

Pretty easy to pop the reluctor wheel off and remove the breaker plate. Then you can watch the weights and springs as you rotate the advance mechanism. Hold the bottom and twist the top. Something's not right in there. It should move smoothly, weights moving outward away from the shaft, and snap back to where the weights are in by the shaft. It does that over and over when in use, sometimes divots get worn in to the mechanism pieces. Things dry out over time also, along with rusting.

-

Weird that the "calibration" procedure is just turning something "about 45 degrees". Implies that it's more of a switch, than a calibration. If it's turned just 35 degrees is the reading off by a small amount or is it back to the 6 cylinder setting? Man, we were mean last month. My 76 and 78 tachs work with a GM HEI module, and a capacitor on the negative post blue wire. Without the capacitor, the needle just quivered. That was with a ZX coil though, with the HEI module.