NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

Your main concern with an unbaffled 240Z tank should be fuel starvation on corners. If the driver plans to drift it might be an issue. With a turbo engine it's an important issue. Proper baffling or the surge tank will solve that. Submersed pumps tend to be quieter than external. Might be nice.

-

Driveline vibration questions

NewZed replied to socorob's topic in Gen III & IV Chevy V8Z Tech Board

Trust but verify. Old cold war saying. Ronald Reagan. -

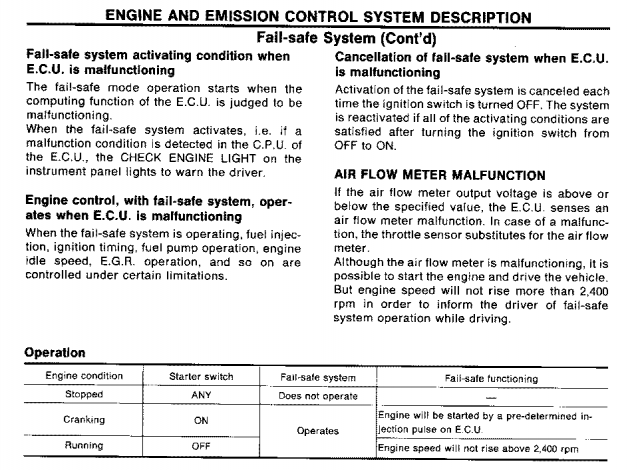

You could use the self-diagnostic functions of the engine's control computer and get at least a small clue. The flashing lights. And if you're using a meter you might as well report real numbers, rather than "really low". Engine control systems with ignition timing and dwell control use coils with really low primary circuit resistance. Having a systematic plan would help also. You said you thought you might have bad gas, but you changed the fuel filter instead. "Hot start" is mostly associated with the L6, not the V6. Wrong engine. It's probably been in fail-safe mode since you bought it. The picture's from 1990 300ZX but Pathfinder is probably the same.

-

"System". Of external fuel pump. 1983 Turbo cars used an external fuel pump. It doesn't need internal/submersible. External is sufficient. If you want submersible for other reasons, that's something else. But it's not the only way to go. Good luck. Read the Surge Tank thread in this same sub-forum.

-

The stock system worked fine with an external pump. The engine doesn't know or care (getting anthropomorphic) how it gets its fuel. You're making simple things complicated.

-

37 psi, by the book. For stock.

-

I would start a new thread in the Troubleshooting section, as suggested to the first guy, and describe in detail what your problem is. Why add to a thread that's already in the wrong place? Your engine doesn't even start now, so not really EXACTLY the the same. Add details like automatic or manual, how many circuits you've checked with your meter, whether or not any fuses have blown, condition of fusible links, etc. The basic stuff. Add whether or not it's ever run, how well it did if it did, and when the problem showed up. There's not much to work with in your post. You can check the reverse switch by disconnecting it also. No need to install a new one until you check the electrical.

-

I don't have a turbo. Better get a Walbro. It's got the name. And rated to 500 HP! Universal. OReilly's isn't gonna fly. http://walbrofuelpumps.com/255lph-walbro-gss342-intank-fuel-pump.html Your post #3 picture opens but the first two don't. Spinning wheel...

-

The OReilly site will pull up some options for you - http://www.oreillyauto.com/site/c/search/Fuel+Pump/C0401/C0025.oap?year=1983&make=Nissan&model=280ZX&vi=1209428&redirectkeyword=fuel+pump I've had the Airtex E8312 in my car for about 40,000 miles. No issues.Just use the rubber wisely to isolate it from any metal, for noise avoidance. Didn't really look at your picture. Maybe you want an internal pump. By the way, there's something odd about your pictures, they won't expand when clicked on. Maybe they're too big.

-

Stock engine rebuild advice - what to ask machine shop, etc.

NewZed replied to 1 tuff z's topic in Nissan L6 Forum

But you're leaving out all of the cost of enlarging the seat area for bigger valve seats for the bigger valves. He already has an N47 also. Plus the realignment of the cam towers, hoping that they work, moving the valve train over, etc. I don't see why anyone would use an E31 on an L28 unless they had to. Just not making sense. How much does that bump in CR buy you, and is it usable on pump gas? He's "not building a high performance engine, just close to stock and reliable." Post #3. Your advice might be good, but it's off-target. He's not building a race engine. -

You should start a new thread. Nothing worse than finding a bunch of clutter at the end of an FAQ thread. The FAQ's are supposed to "all killer, no filler". Not frequently asked questions answered over and over again.

-

Stock engine rebuild advice - what to ask machine shop, etc.

NewZed replied to 1 tuff z's topic in Nissan L6 Forum

So, basically, you're going to spend a lot of money to avoid having liners in the exhaust ports? I'd source an N42 head, send it to Slover and be lots of money ahead. Same end result, much cheaper. If you have the pile of parts, piecing together valves and castings with machine work might make sense. But the N42 is already there. -

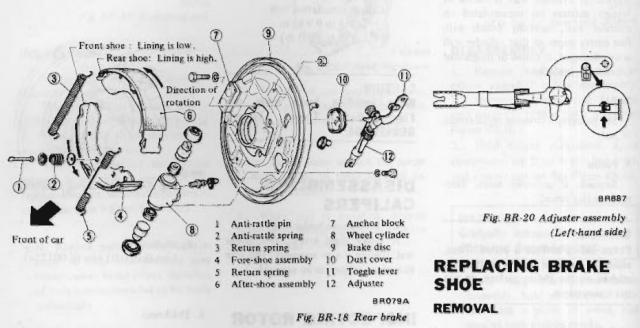

Rear brake drum spring woes

NewZed replied to rickyellow zee's topic in Brakes, Wheels, Suspension and Chassis

Put the shoes and springs together off of the backing plate, on a bench or the floor. Fold the shoes toward you like closing an open book, keeping the springs in their holes, using the springs like hinges. Place the various contact points of the shoes and mounting areas of the backing plate together and push the shows flat like opening a book. The springs will stretch as the shoe ends get pushed apart. Use one hand or a helper or a rope or string or bungee cord to hold them in place while you insert the pins from behind and lock them down. Can't remember but I think that you might be able to mount the adjuster between the shoes after the shoes are mounted, or hold it in between the shoes before you place them on the backing plate. Anyway, if you try it, the fine details will fall in to place.. -

Stock engine rebuild advice - what to ask machine shop, etc.

NewZed replied to 1 tuff z's topic in Nissan L6 Forum

He said that he thought the E31 head was worked on. The N47 already has the bigger valves. Why not just have the N47 head worked on? The exhaust liners? Is it exhaust or intake where the L heads are restrictive? Tony D mentions E31 mythology, is there much to be gained with the E31? I would assume he will use carbs so my brain says drop the L28 in, unmolested, and spend the time and money on getting the carbs tuned right, if they're even the right carbs for a bigger engine. 17% more displacement, with an engine that should be good for another 100K miles. The Nissan factory really seemed to do a great job on putting these engines together. Thank Deming. -

E brake stopper missing.

NewZed replied to rickyellow zee's topic in Brakes, Wheels, Suspension and Chassis

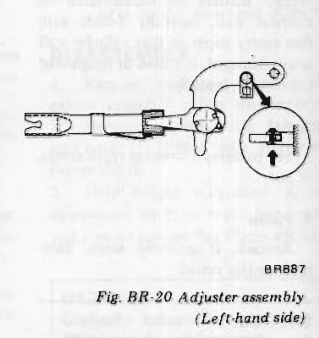

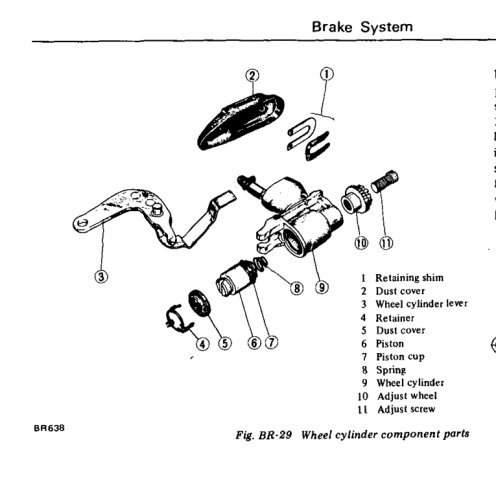

Without that piece (which I would call a "rest" or "stand-off" or similar, just saying. I think of "stoppers" as things a the end of motion, not the beginning. Not that it really matters.), the adjustment arm will be in the wrong position to turn the wheel. Wasted movement with no adjustment happening. It's important. -

E brake stopper missing.

NewZed replied to rickyellow zee's topic in Brakes, Wheels, Suspension and Chassis

You could always put it all together and see how the missing piece affects operation. Since you have things apart. That would be interesting. -

E brake stopper missing.

NewZed replied to rickyellow zee's topic in Brakes, Wheels, Suspension and Chassis

Two wrongs? Notice the parentheses in your link. Anyway, most parts on critical components, like brakes, are there for good reason. I'd put it back to the way they designed it. -

E brake stopper missing.

NewZed replied to rickyellow zee's topic in Brakes, Wheels, Suspension and Chassis

Seems like it could affect operation. It positions the lever at rest, and doesn't allow the adjust to travel too far. You could probably fabricate one pretty easily. And it's just a hand brake, mostly for parking. Or limping home. Have you ever tried to stop the car with it, at any speed at all? Just a distraction in an emergency. -

E brake stopper missing.

NewZed replied to rickyellow zee's topic in Brakes, Wheels, Suspension and Chassis

Why are you calling it a "stopper", whatever it is? Hard to tell what you mean. Can you find the part on the attached picture? I picked 1976 because that's the car I have. Although my rear brakes are 78. They're different. What are you working with? -

The throttle linkage just pops apart. It's a ball and socket connection. Get big screwdriver, position it between the pieces, and twist. You might consider some type of load leveling device, either self-made or bought. The transmission has a lot of leverage on the back of the package.

-

Read Post #9 - welded - and look at these threads and web site. http://forums.hybridz.org/topic/78123-subaru-wrx-sti-r180-side-axles/ http://forums.hybridz.org/topic/93316-subaru-wrx-sti-r180-side-axles-part-deux/ http://www.wolfcreekracing.com/index.php?option=com_content&view=article&id=22:tranny-a-rear-diff-parts&catid=16:tranny-a-rear-diff-parts&Itemid=31

-

Advice - cut the plug from the old external regulator and do your splices there. It will look cleaner and you can go back easier if you decide to. And you will need the diode.

-

Driveline vibration questions

NewZed replied to socorob's topic in Gen III & IV Chevy V8Z Tech Board

Can't get much cheaper and simpler than swapping some different wheels on and going for a drive. -

Post what you've seen so you don't have to see it again.

-

Why would a new post on "the forums" be better than an old post on "the forums"? Aside from that, the ZX propeller shafts are all different lengths than Z propeller shafts. So you'll have to have whatever you get cut to length. According to the FSM, the NA propeller shafts are identical, manual to auto. Same part number. But the L28ET uses its own shaft. My impression has been that the slip yokes are different. Borg Warner and Nissan spline counts and shaft diameters are different. If you have the parts, which it looks like you do, you could measure and count. Or take the BW trans. with you when you pick up the diffs. Or count and measure the BW, then count and measure the propeller shaft. Or take pictures and compare. I wrote all that stuff then realized you only asked about the "auto diff". Which doesn't really have anything at all to do with the 5 speed B/W. Good luck.