NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

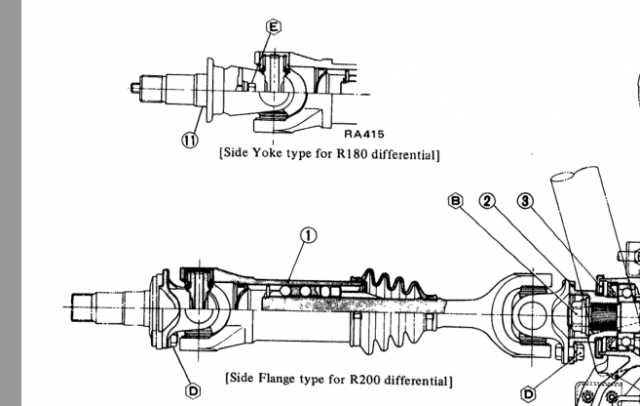

I would read jmortensen's diff thread in the FAQ section. You might have some changes from stock. A welded R200 might be going backward. Or maybe Nissan converted to clip-in axles with the 280Z R180's. Edit - actually that picture I posted is from the 77 FSM. So what you have doesn't match. http://forums.hybridz.org/topic/49194-differential-cv-lsd-hp-torque-r160-r180-r200-r230-diff-mount/

-

-

Without exceeding the speed limit, of course.... Drive at your own risk.

- 6 replies

-

- speedometer

- speedo

-

(and 1 more)

Tagged with:

-

The trip meter shows that the cable is turning. The older speedometers use a rotating magnet, and a cup or disc shaped thing, and a spring to show speed. There's pictures out there is you search "how a speedometer works". You probably have a spider web or some sort of crud in the mechanism, its kind of sensitive. You could try to spin it free by driving really fast or use a drill motor on the cable end, or take it out out and see if you can break things loose by shaking it. Or take it apart and see if it's cleanable. There's a nice picture in this link - http://www.uniquecarsandparts.com.au/how_it_works_speedo.htm

- 6 replies

-

- speedometer

- speedo

-

(and 1 more)

Tagged with:

-

Firstly, you should probably start your own thread, describing what you're trying to do. Talking about getting an old engine running at the tail end of a thread about shaved intake manifolds won't draw much attention. Second, that's not a stock combination of parts. But you should be able to get it running well with the stock ECU, others have done it. But it's a low compression ratio engine. It's already at the typical turbo engine compression ratio. But you should know that already, it gets talked about all the time. Not many people, if any, run electric water pumps. With that pile of parts and planning for electric water pumps, you have a lot of work ahead. Probably best to just get some new gaskets and start bolting the parts together. Get the engine in the car and get it running. You can bolt any turbo parts on with it installed, and convert to Megasquirt too. Getting it running in "stock" form will let you know if the engine is even worth keeping, and you can learn as you go, and drive the car.

-

Coolant flows from the block to the head. The gasket would be designed to control and balance flow in to the head, I would think. So if all of the holes in to the head are open, you're good, the gasket can do its job. Seems like the gasket that matches the head would be the way to go. If there are holes in to the head that don't have a matching hole from the block then that's where working on the block to give the head what it needs might matter. I haven't seen where anyone's done that but maybe it happens.

-

Urethane Steering Coupler Bushing Difference

NewZed replied to AdreView's topic in S30 Series - 240z, 260z, 280z

The eight holes are two different four hole bolt patterns. Designed to fit two cars. Pretty sure the pattern changed somewhere on the way from 240Z to 280Z. -

It always helps to describe what you do know, no matter how little. Just to show that you're a good investment. Or at least post some pictures for entertainment value. If you can't figure out the cold start injector, Megasquirt will take forever.

-

Howdy pallnet. I have a question about the barbed rails: do you, or can you, use 1/8" pipe thread for the 5/16" barb? If so, the rail could be drilled out later for 14mm o-ring injectors, if desired. The 1/4" pipe thread is too big on the big end and would be a problem to drill out. Asking for future reference.

-

The exhaust fumes in the cabin problem is written about all over the internet. Still seems like you might have two problems, or more. The exhaust on my stock L28 smells so sweet sometimes I lean down and take a sniff just to know that things are stilled tuned right. I enjoy when a breeze of exhaust blows in through the window. It was only close to horrific quite a while ago when my FPR went bad causing a super-rich condition. My engine is catalytic converter-free so the smell is unprocessed.

-

Unusual Rear Sway Bar Mount

NewZed replied to Phantom's topic in Brakes, Wheels, Suspension and Chassis

I don't know when Nissan changed the mounting point. Could have happened before the 280Z. I think that the interference with the fins is from the transverse link mount, or cross-brace (I can't figure out what Nissan calls it). The curved, stamped steel piece that bends around the back of the diff cover. -

Unusual Rear Sway Bar Mount

NewZed replied to Phantom's topic in Brakes, Wheels, Suspension and Chassis

That is the normal way for a 280Z. Those look like factory bars and mounts. The rubber even looks in decent shape. -

Rolling with the punches a 75 280Z v8 Refresh

NewZed replied to hwvigo's topic in S30 Series - 240z, 260z, 280z

Your local Nissan dealer might be ab;e to get them or Courtesy (the link). Spendy. http://www.carpartsmanual.com/datsuns30/DatsunZIndex/Axle/RearAxleDriveShaft/tabid/1730/Default.aspx http://www.courtesyparts.com/bolt-drive-p-353949.html You should run solid mustache bar mounts (no rubber on the ends) with a solid front mount. Otherwise the solid mount will take all of the load, while the mustache bar wings just float and do not much. People have had the cross member metal fatigue and break with solid front mounts. -

Sounds like garden variety exhaust system leaks. Lots of flanges and gaskets to leak from on a turbo engine.

-

I didn't really read all of your first question, sorry. I thought you were selling or asking in general. Since you'll probably tear it down anyway, I would take some tools out there and take it apart as far as the guy will let you, to see how things look inside. All it takes is one rainy day uncovered out of those 750 to get some water in a cylinder that sits in there and rusts. At least take the oil pan plug out and see if water or oil comes out. Water will condense frm just the air and sink to the bottom. Good luck.

-

In this new age of information, with so many people spelling out in detail how to get the most power out of these engines, it's amazing how many new people end up with the same plan, from the same sources, that will provide no real increase in performance, maybe even a decrease, spending money on things that probably don't even need doing. Maybe the shrinking of the technology interface to phone size has counteracted the increase in knowledge available, leaving most people at the very same place they would be in the 1980's. Fascinating! rick240, browse through the FAQ's and you'll probably realize that none of what you're planning is really worth spending money on. Seriously, I'm just trying to help. You could get an old 280Z or 280ZX engine complete and spend time tuning it to run right, without even cracking it open and probably be better off and save money. The F54 block was introduced in 1980 for NA and turbo engines. Don't listen to your adamant friend anymore.

-

You're kind of rambling all over with the driving, and the sitting in the driveway and fumes in the engine bay escaping and fumes coming in through open windows. Creating a vision of a car sitting in a cloud of noxious fumes. To your specific question about a rich mixture overpowering gaskets and metal to "escape" versus a lean mixture - no, all gases behave the same. Although, if you've modified your PCV system, blowby could be escaping in to the engine bay. If you can get all gases to exit via the hole at the end of the exhaust system, you should be bale to keep them out of the cabin by sealing the perimeter of the big vinyl covered panel on the inside of the back hatch. Several people around various forums have described this. Don't worry about all of the small holes on the outside, just focus on sealing the edges of the trim panel on the inside. Stick-on weatherstrip works well. The cloud of fumes while running in the driveway should be handleable by idle tuning (obviously). Idle tune is typically a whole different world from driving tune, both ignition timing and air-fuel ratio.

-

The wrecking yards in my area give a one month warranty, plus you can buy a year-long warranty if you want, for not a lot. Just saying, they really are the competition, for the discerning shopper. Hook everything up and get it running and you can ask a premium.

-

How much does the local wrecking yard charge? That's the competition.

-

Somewhere in one of his other posts he mentions that the car is being built for his 15 year old son. Teen + drift + welded = problems.

-

Guys from the world of old Chevys are used to removing the axles, and swapping the internals. Example in the attached link. The OP writes like he's thinking that way, like the Z diff swap is difficult. He's working on a car for his 15 year old son, and is also thinking the "T5" is something special. Now you know. http://www.superchevy.com/technical/engines_drivetrain/driveshaft_rearend/sucp_1208_10_bolt_differential_upgrade/

-

With IRS the differential is not connected to the axle housing like a typical older American car. So a differential swap usually just involves swapping the whole external case and everything with it, not just the guts. Many times the back cover is not even removed. It's not like a Ford or Chevy diff swap. Remove the four nuts holding those axles on to the diff, drop the axles, get a another diff, install it in the car, then bolt the axles back up. After greasing the u-joints on the axles. It's easy. Saw your other post about "reverting" to a 3.54, and your posts on the other forum. This should make your decision much easier.

-

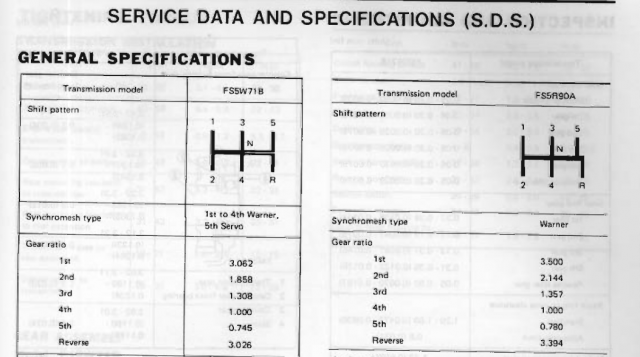

The 240Z's came with a 3.592 first and 3.36 rears (12.07). The 280Z's were 3.321 with a 3.54 (11.75). The NA ZX's were 3.062 with a 3.9 (11.94). You'll be at 13.65 (3.5 x 3.9). Lowest first gear ever. Swap to the diff you don't want to hear about and you'll be at 12.93, still lower than any factory setup. There's always big tires. Edit - just realized that the 3.54 combo won't be lower than any factory setup. just lower than any factory 240Z or 280Z setup. Using the 3.54 just gets to the factory 1983 Turbo 280ZX gearing, Lower overall, probably to help with the ~500 lb weight increase (Wikipedia weights), from a stop.

-

Front Wheel Not Centered

NewZed replied to padam07's topic in Brakes, Wheels, Suspension and Chassis

I still have rub marks on the inside front of my fenderwell from when I broke a TC rod while parallel parking. Without the TC rod, there's not much keeping the control arm from moving back and forth. Everything is rubber-mounted. -

Curious how to quantify "smoke". Is this butt-dyno, real dyno, 1/4 mile times? 11% more displacement, but much more than 11% increase in "power". The OP's engine seems to be basically an enlarged stock ZX-style engine (flat top with P90 head) with a Schneider Stage 2 cam and a 9.9 CR. But the 11% increase in displacement doesn't seem to be giving the 11% increase in power. Just looking for details. Of course, the old dyno vs. dyno variance factor comes in to play also.