NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

Pretty sure that the L28 will swap right over on to the current L24 auto trans. Why would you think any differently? They're the same block. Make sure you swap the spacer over also from the L24's crankshaft.

-

Best to just get a meter and make sure power is getting where it needs to go. The EFI system has its own fusible link, inline on the supply wire at the positive terminal. It's green.

-

He's saying that the starter gear is getting bound on the flex plate? Seems like a stretch. Cheaper to try a new starter first. You could probably examine the flex plate through the starter hole too.

-

People sell cars without titles because they were unable to get the title. This has big mistake written all over it. You're wasting your time. I wouldn't take it if it was free.

-

So shipping costs or gas for the drive. How is your locale for emissions? 280Z's are usually in the emissions testing range, for idle at least. Clear title? Dealing with title issues from distance can be difficult. Looks like a lot of work for not much.

-

240Z clutch master cylinder clevis

NewZed replied to Mike Mileski's topic in Brakes, Wheels, Suspension and Chassis

Click on the first link I provided, then click on Clutch Master Cylinder, click the year range, and you'll be able to find a drawing of the piece you're showing. Not sure why that wasn't clear. Click, click, click, drawing. $9.xx at Courtesy Parts, plus shipping. It comes with the rod though. Why would anybody sell just the clevis? I'm surprised that Nissan sells the rod and clevis as a separate item. If you're master cylinder isn't factory stock, then you're just shooting in the dark anyway. Edit - a closer look shows that Nissan does sell just the clevis. Weird. They call it the "Head". $3. Assuming that they actually have it. -

Interior pieces are hard to find in good shape. A nice interior adds some value. You should break things down based on what you want to do with it. Is it a project to work on, a driver that looks nice inside and out, a performance car, a base for an engine swap, whatever. It's basically a 280Z that's been messed with. The bumpers have been swapped and the EFI has been removed and replaced with carbs. You'll spend a lot of time and some money getting the carbs tuned. they're probably tuned for the 2.4L engine they came from. Pennsylvania uses a lot of salt. There's probably a lot of hidden rust. The 50K miles is probably 150K.

-

240Z clutch master cylinder clevis

NewZed replied to Mike Mileski's topic in Brakes, Wheels, Suspension and Chassis

Looks like you can get it with the rod. Maybe, assuming they really have it. Try your local dealer. http://www.carpartsmanual.com/datsuns30/DatsunFairladyZIndex/PowerTrain/TransmissionCase/5Speed/tabid/1702/Default.aspx http://www.courtesyparts.com/ -

280zx Turbo start up problem.

NewZed replied to jbh1212's topic in Trouble Shooting / General Engine

Sounds like the fairly common "heat soak" or "hot start" problem. Search those terms on the interweb and you'll find some good reading. What you describe and what you say the previous owner described look like two totally different things. Your problem is immediate, his/hers happened after 10-15 minutes of proper running. -

Maybe it is running really rich. What's the fuel pressure? What did you do with the gas tank vent lines when you took the canister out? Did the gas smell exist before you made these changes?

-

Gasoline in the oil? I filled a crankcase full of gasoline once with a borrowed carburetor that had had the float bowl needle removed. Small block chevy so no external leakage was evident.

-

Probably waiting to see what happened this morning. Did it thunk? Metallic is usually clang or clank, not thunk. So that part was a little confusing. Free turbo engines...I'll take one too.

-

The NA 280Z EFI system is not a good way to run the 280ZX turbocharged engine. You could have a mismatch between the ECU and: the injectors (they're higher flow rate on the turbo), the TPS (three position for the Z, two for ZX), the CAS (not connected in your case since the 280Z ECU doesn't use one), and many other components. You probably already know that people will recommend Megasquirt. After re-working everything to use the 1980's technology, you'll still have just 1980's technology. The first thing that you should do is make a list of the parts you have. Engine block, pistons and head (P90, flat-tops, dished pistons, etc), CAS, TPS, turbocharger, turbo control pieces, etc. Then you'll have an idea of how to get things working right. You should stop trying to drive the car in the meantime. It's pretty easy to damage the L6 with with a turbocharger, especially when it's being boosted over spec., using the wrong ECU, and a bunch of mismatched parts. All you really have that's useful is a car and a turbocharged engine. Looks like your car could use a lot of work. It's not stock by any means so the factory service information won't help a lot. Post #31 in this thread. "Perfect" is a relative term, even though by definition it's absolute.. http://forums.hybridz.org/topic/67930-in-progress-75z-getting-81zx-turbo-motor/page-2?hl=scoutman75

-

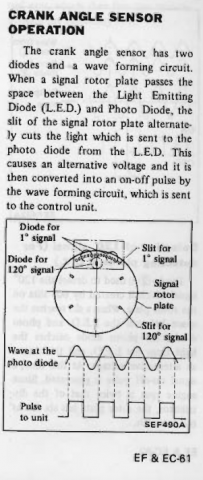

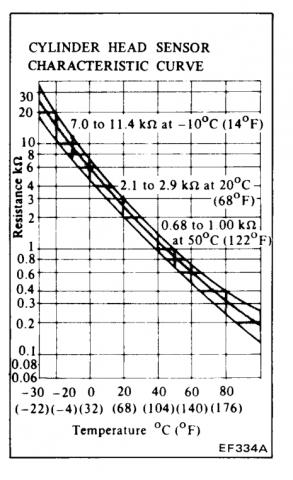

You're probably just measuring at the wrong pins, or wires. The drop to 4.75 is probably "on" and 5 is "off". There's a voltage drop when the photo diode is switched, I would guess. I wish I had one of these, they look like fun to play with. Nobody ever shows what wires they're measuring so this problem, and any solutions, never get clearly explained, I think that what Nissan calls a photo diode is actually being used as a photo transistor. When the light from the LED hits the photo diode, current flows and it's "on". LED light goes away, it's off. Or it may actually convert the light to current but that seems like it would be a pretty weak pulse, converting one LED light in to a pulse. Who knows for sure... Anyway, draw up a diagram, or take a picture and show where you're measuring voltage. There are guys on this forum who know exactly how these things work. Note that there are actually two different wave forms generated. Ideally, you would confirm both.

-

The 85's you two are comparing are probably from weather stations in the shade at about 6 feet high or more.

-

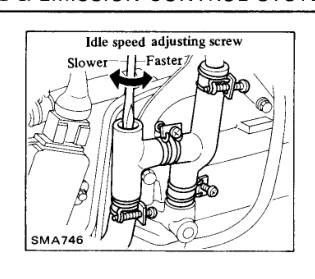

If you prop the throttle blade open far enough your ported vacuum becomes full-time intake vacuum. Could screw up some other functions.

-

*hypothetical* "Bolt on" throttle body carb replacement

NewZed replied to XplosiveLugnut's topic in Nissan L6 Forum

You've just re-invented throttle body fuel injection, abbreviated TBI. Hit the Google to learn more about your new old idea.- 19 replies

-

- fuel injection

- efi

-

(and 7 more)

Tagged with:

-

Clutch engaged at all times, can't get out of gear when car's on.

NewZed replied to AzureChris's topic in Drivetrain

Looks like two separate problems, as implied in Post #6. Shift linkage, or shaft misalignment, inside the transmission, and bad or un-bled clutch hydraulics. -

-

-

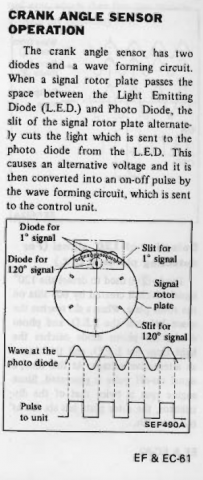

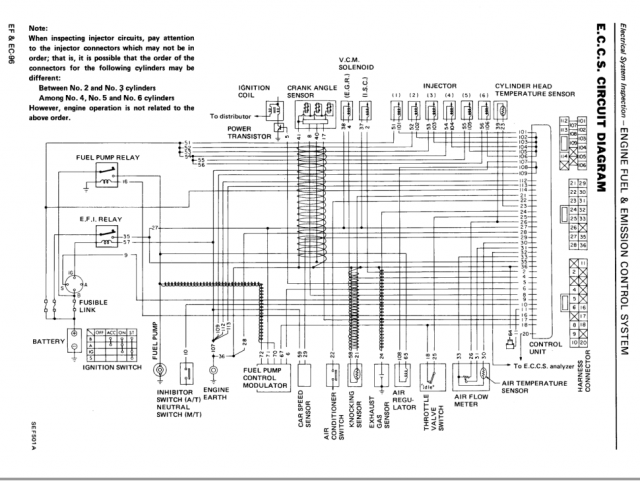

That's one way. The ECCS system probably runs the CHTS ground through the ECU. The better way to confirm that the ECU is getting what it needs though, would be to measure resistance to ground at the ECU plug and compare the resistance to the temperature versus resistance chart in the FSM. Continuity doesn't really tell you much. Study the diagram for the ECCS ECU and you'll probably be able to figure out which pin is ground and which is the temperature circuit. Check resistance of your other ECU grounds while you're in there, you might have high resistance on the main ground circuit which is giving high readings from the CHTS.

-

Check for continuity to ground on the other side of the connection at the CHTS. The ECU sends a voltage out that passes through the CHTS on its way to ground. One pin to the ECU, the other to ground. No ground is like no CHTS.

-

Stuff to check. Highlighted the non-electrical. Note also that their web site says the pumps are rebuildable to "as-new" condition. Polymer wear plates worn, perhaps. Q. Why is my fuel pressure too low, or I have no pump pressure? A. Check the voltage to the pump, relay switch. Could be faulty. They can be bad without going out. Weak relay reduces voltage. Replace them. Check wiring, look for an improper ground. Check the battery voltage. Check the filter and inlet line for obstructions. Look for leaks on inlet side. Adjust bypass. Is there debris in pump bypass (poppet). The bypass valve could be stuck open. Clean filter. Replace deteriorated fuel-cell foam. If no pressure, the pump may be operating in reverse. Check the wiring diagram. No fuel in fuel cell, or fuel cell improperly vented. http://magnafuel.com/support/index.htm http://magnafuel.com/products/efi/pumps/MP-4301.htm

-

Trouble Getting '73 Hybrid Starting and Running

NewZed replied to perspectiveshifting's topic in Ignition and Electrical

Seems like you're focusing on spark but the problem might be with fuel. You said it started and idled, and that you have spark. How old is the fuel in the tank and carbs? How strong is the spark? Strong and blue or weak and orange? Modules have been known to partially fail. You might check spark and timing would be with starting fluid. Have someone squirt a few shots in while trying to start and have them try to keep it running with the fluid if it catches. -

Can't remember something that wasn't mentioned. Your first post sounded like you just put a new system together, with old relays, and had problems. If it's a new problem on an old system that used to work, that's a whole different thought process. So, is everything 3-4 years old, and the problem is new, just out of nowhere? Or are there new parts, and a new problem? Did the relays you changed have any effect? Correlate the changes and a cause-effect relationship might pop out. Good luck. Don't get side-tracked.