NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

Just to focus a little more, the extra juice when running directly from the battery is probably over-powering the blockage. It shouldn't take 10 seconds to get to 42 psi. You might be overheating the pump due to low flow from a blockage or a too-small inlet filter. The key though, is that you hear the pump spinning and you're not getting pressure. There's something odd about the specs on that pump though, The Summit Racing site says it draws 14 amps at 45 psi. That seems like a lot of amps. Anyway, try it without the pre-filter and see what happens. http://www.summitracing.com/search/product-line/magnafuel-protuner-750-series-in-line-fuel-pumps

-

Does anybody have more info on this car?

NewZed replied to Turbo6.0's topic in S30 Series - 240z, 260z, 280z

Learned this trick on a different forum - right click on the image and you might get an option to search the internet for that image. It works with Chrome, I don't now about the other browsers. It worked for your image. https://www.google.com/search?tbs=sbi:AMhZZisCEH6AzzhnafBNrxStSiX8zrZAv9KVcbTg3tBwGznxnxEA2s6MSlDdQ_1Pt3W_1mYKa7eypuNyaWIF9rI3a1fiCbRa0LiNi-3_1CyB1cyy-uAVQxZOWYKNfmcy4cDCNGP4hI6Le0pnqHujN8mSzpxO-qs5k48wF0YOyWqf9gXnpog9dSqTDoSZY5mhdqTGk95rlYJMMiF4mqywHy03VpFUr1Cekhy-R1ZzNmY8yLjuQynGELvi5B9nmVa5FLADul3g3BE0HgyHdq4S68T7Gzzp_1vdP4600B93BAj8iFQAquM69Y2jpJKn88z8H6pMLeQMTI8ms8FzslimjzPLRWjL4CF_1H9hi6IDZqVgo49on0ksQk3LXO_1OA5RcFzUAZbxRUZJpvRegqHozfcWWlp8IoU2WlYHmYtVHjevS6J-D_1p4R0dQI2IydBhpYwJqPRmg-Ay8VE1zzrIz2VxzVRi3VXkFQ8I1ReJrsceLCvVsqmMncGFu3NbotN1PRsHOQeySk-0LQIhEQurifKY0LEORCT4FYrMwjSQXKrByKguE6tY_1ZDcGuCmimLOAisPc8KE3-2qGBabg68h94hSJ352D5X2vZk8LImN62eCDXSTBT-vibq5iZ-XjAG6cLvnPT6R4Zy-DF8_1ye2edQhjr4ks4v4j6oXZuB_1k9EfojvgbEFedlJ4K4LL5laVbnMgeJgzHcxCX5sK0sLQlOuHs3Ew8fLwnHRuECHOcdyQMbDfHntu_1L5YVQjbA2zJDKtHuDzDzIYp4MoYb28Ls7JVaxwmeB33MrZBjte_1SlE9Phe5ydLl0OSSOypcPDbO5clEmcgNV-rBvTEGm34610uNmkN1XNaoWSO8jvsVGMVwRW0a2VU5nbkBbvvEOQ5Irlta7lfIiKNFBL4BEt2c8epQxQKcUJvtO-tt2ZQT51_1LWHebwIQ-d6qB_1tpKoT8O5piu_10CMMtetIg7PsK5ZdLIZevA6CQCCIP7adLACZ4hUnhMzr9gqZPXfBDzy0-3YdEuSpX6t5-_1D6qLgRCDBLQvO809w_1_16egzjOwVes0raFvOBWr_1vOZdi2Iiy4B67BhAJfDWOh3eHQMHwuI_1FxHOBW-07gGwzXPGPVku0kO-GPwG6yrERThziV_1wTZ7VZkMKsxO_1i4BUNnhH9gTwcmPqq0uL7ArmgNbBXgJoeXX5stJwKI-z2ZtNw6v6d4abatl8nOzym39-Ff2q6TiM8hrVTB2jsubLnKVfoZsJGlWRjYv-a9s5cK5vJJ-hjT2df504dIVCcpY5gtOg07-iPTnmrXf2xAWvPRAQ6aNafUGVWyg3BJ1fRzmdt1NOjwfAlCp6e9y7LMeaXGIpmVKGlmUTltIePFN5jmWU3Fzs6ggTAApkORuXMAl7c-qJ38p2TXTJAhmy_1t-ZmnViqKg9jqfhaN8t0U9fD1sRGcKoVB-6mFxgvdlvzFo3rGTkRqCf9VXOuopUoWVLL2ZkLr3EBI -

It doesn't look like an electrical problem.

-

None of these threads are any good? http://forums.hybridz.org/forum/35-nissan-v6-forum/

-

Here's a fun one. 5000 RPM cut and misfires

NewZed replied to Watson's topic in Trouble Shooting / General Engine

When the engine is running,throttle closed (idle) there's about an 8 psi differential between inside and and out. Your smoke test probably has less than one psi differential, if any at all. Pressurize the manifold with the smoke inside and see what happens. Just a guess. You didn't give any details on what the "smoke test" is. -

This thread, Post #15, implies that you only added 100 lbs, if all you did was go from aluminum to iron blocks. You said it had an LS1 before. That 100 lbs seems to be having a larger effect than you'd expect. Is their extra stuff hanging off the front like AC compressors and power steering pumps? http://forums.hybridz.org/topic/59086-enginetrans-weights-definitive/ I'm no LSX engine expert but I think that the blocks for the Gen III engines are all essentially the same. Maybe the ZX just isn't suited for a V8 swap. It would be interesting to know the weight balance front to back of the car, as it sits. Even if you get the heights corrected, you might still end up with a wheel-spinning monster. Here's a good read on what you might have. Maybe you can make some adjustments. Looks like a fun problem. http://www.jagsthatrun.com/Pages/Parts_DATZX_MountingInstructions.html And another - http://www.jagsthatrun.com/Datsun-ZX_Order.html

-

Does it not move at all, not read correctly, or twitch and jump? I had a combination of ignition module and coil that caused my tach to twitch and jump, and only read from zero to ~1500 RPM. An extra condenser (capacitor - the typical silver can from the distributor mount in this case) on the negative terminal of the coil removed the noise. I couldn't explain the details of why it worked, since I don't even really know how the tach works.

-

I only posted to help you clarify your issue. You should post in a ZX forum since your problem is with the ZX suspension. Seems like you might also have an issue with motor placement since the LQ4 is not supposed to be that much heavier than an L6 (100 lbs more?). Your front suspension "smash" seems excessive and the back end really shouldn't have raised, unless the new motor was placed ahead of the front suspension center line. I'm no expert though, and haven't swapped a ZX. Give some details on the swap.

-

So do you want to lower the ass end or raise the front end?

-

You can dink around on the Dorman site getting the search format right and choosing the right numbers, to find some options. Other sites, like Summit Racing, tend to have explicit descriptions too, that will let you narrow a search. It takes a few iterations. Oreilly Auto is another site that has detailed part descriptions. I've found also, that using the the "site" term in Google will find many things that a company's own search engine won't find. I usually make one search to see the format, then just replace numbers with partial numbers, like 0.5 instead of 0.509, to narrow. Here's the Dorman page and an option. It could be narrowed further with a specific knurl diameter, the 610-409 part just happened to be on the first page. http://www.dormanproducts.com/gsearch.aspx?type=keyword&origin=keyword&q=wheel+stud+M12-1.50+Serrated+Wheel+Stud http://www.dormanproducts.com/p-32691-610-409.aspx?origin=keyword Edit - meant to add also, that the OReilly and Dorman sites both show the 350Z as a .5649" knurl. I used 2006 as the year. http://www.oreillyauto.com/site/c/detail/DAG0/610378/02990.oap?year=2006&make=Nissan&model=350Z&vi=1433005&ck=Search_wheel+stud_02990_1433005_-1&keyword=wheel+stud&pt=02990&ppt=C0337 http://www.dormanproducts.com/gsearch.aspx?type=keyword&origin=keyword&q=610-378 And, sites like OReilly have a "Compatibility" page for each part that shows the cross-reference Tony D mentioned. Pretty handy.

-

Look for value. Receipts and proof that a pro rebuilt the head, versus some guy in his garage. New valve seals don't count as a rebuild. How many accessories and what shape are they in. An old worn out alternator isn't worth much. You can get a used engine form a wrecking yard for about $350. Is it worth $250 more for what you're going to get. Since you're in jail you should be looking for cops on the drive out.

-

Spend some time thinking about the "givens". Many of the popular mods are popular for irrational reasons. Some have been shown to be ineffective. Some of your old parts might be fine. On the future - if you're going with EFI over the 4-barrel carb, then the surge tank sytem, fuel cell, bugger fuel return lines, etc. make sense now. If not, maybe the stock system is fine for a carb.

-

A simple method of replacing rear strut cushions

NewZed replied to docjim's topic in Brakes, Wheels, Suspension and Chassis

For those with 280Z's - the rear strut assembly is too long, longer than the early S30's, to slip out from under the fender well without loosening the inner rear control arm bolts, unless you put a lot of pressure on it. The 240Z's do seem easier to get done. On the nut - you can stick a bar or long screwdriver between the three studs to get leverage, with the strut assembly out or dropped. It's shown that way in the FSM's. Or dill two holes in a piece of steel to set over two studs. Everyone's got their own little tricks and most depend on what tools you have available. Some let the stock springs fly when replacing with shorter springs, if they don't have a spring compressor.. -

A simple method of replacing rear strut cushions

NewZed replied to docjim's topic in Brakes, Wheels, Suspension and Chassis

Loosen the center strut rod nut before doing anything else. A socket wrench will work, no vises or impact wrenches required. -

Posted Today, 01:03 PM Actually I'm running Windows 7 64 bit under the latest IE. Mine works. Pasted the above from Post #5. I have 32 bit Windows 7, with Chrome browser. Text will cut and paste, images won't. Maybe there's an image in the text you think you've cut. For quite a while I had all three of the main browsers installed. Each one had its own strengths. IE and Firefox bloated and slowed pretty rapidly over the last year though. Chrome works great. As far as privacy, it's pretty apparent now that there is none, no matter what browser you use. Pasted an image below just to be sure. edit - well I guess some images do paste. Better. Administrator Administrators 9177 posts LocationLa Habra, CA, USA Posted Today, 03:27 PM Then the issue is the latest IE. Like This ----- John Coffey, Fabricator at Benton Performance, LLC Quote MultiQuote Add As Video

-

car stalls, then recovers, in motion

NewZed replied to heavyweight280's topic in Trouble Shooting / General Engine

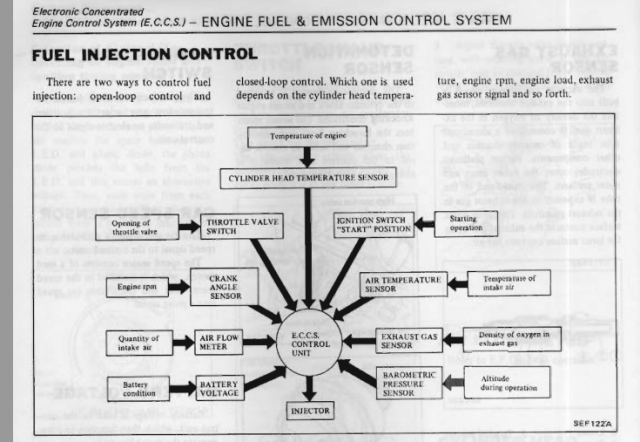

That's a capacitor, AKA condenser. It knocks down electrical noise from the ignition system. If you have a decent meter you can test it. You can replace it with an alternator capacitor or your Nissan dealer probably has one. They're common to many cars. Just because you have fuel pressure that doesn't mean that the injectors are opening and delivering fuel to the engine. You can have spark and no injector opening, and get a no-start. Best to confirm no spark, using a tester or a spare spark plug. Also, the EFI system has its own power supply. You could have power to everything else, but none to the ECU and injectors. If your fuel system is in good order, it will hold pressure without the pump running. Carry a good meter and a spare spark plug in the car, and have a testing plan ready for next time it happens. There are a few key things that you can test within about 5 minutes, that will tell you more about what's really going on. In the meantime you could open and clean your power supply and ground wire connectors to the EFI system. Often overlooked since there's no reason to disconnect them. They're exposed and they get dirty and corroded. -

R180 uses a bolt. R200 uses a circlip. Labeled drawings in the Prop and Diff chapter, with instructions.

-

Turbo engine vent routing n42 intake manifold

NewZed replied to elishallen's topic in Nissan L6 Forum

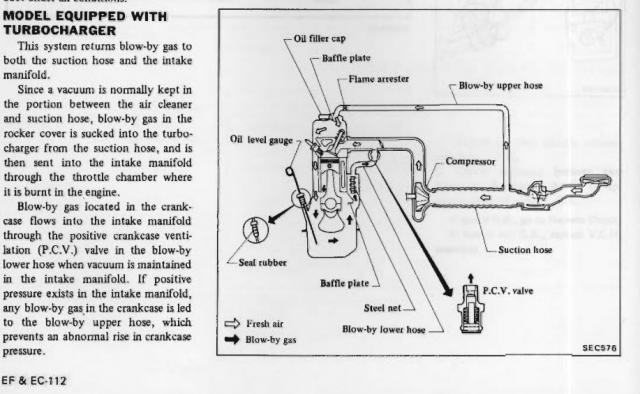

Looks like you have everything running in to a cluster of an air-flow cross-road intersection. Doesn't really fit the concept shown in Post #6 (see the arrows, fresh air and blow-by gas?). Does it run any differently?- 10 replies

-

His rub on the inside CV. You're showing the outside. How close are yours on the inside?

-

Turbo engine vent routing n42 intake manifold

NewZed replied to elishallen's topic in Nissan L6 Forum

Actually, the small area of the dip stick exposed to pressure probably isn't enough to lift it out. I made a funny. With the PCV hose connected to the J-pipe you'll be pressurizing the crankcase under boost. You could fab in a PCV valve to get back to factory specs. The AAR passes air across the throttle blade to let air past the throttle for higher idle speed. But, the air is still metered by the AFM. It's not clear if you left one of the three hoses from the T open or capped all of them. The FSM's cover a lot but it's pretty spread out over the pages and there are some weak areas. Like how the AAR is plumbed in the turbo/ECCS system (the pictures have no detail. But, in general, the crankcase and intake system need to be completely sealed from outside air. All air must enter through the AFM. No exhaust probably means no O2 sensor. So you're in open-loop all the time. With the N42 intake you've probably removed some of the vacuum control valves also. They have an effect. There's a lot of stuff needed to make the engine run right. I don't have a turbo car but I like to keep up with what they need, for future reference. Good luck. Pictures are from 1983, 1981 might be simpler.- 10 replies

-

The firing order you show is wrong. Anti (counter)-clockwise is right. When you get that corrected, consider that the fuel may be stale. Starting fluid is always a quick way to check for spark, firing order and timing. It lights up easily.

-

Turbo engine vent routing n42 intake manifold

NewZed replied to elishallen's topic in Nissan L6 Forum

Is the dipstick still in its hole? Have you tried boost yet? .- 10 replies

-

-

Drivetrain 'slop' Question for Turbo Car

NewZed replied to BlackdogNY's topic in Ford V8Z Tech Board

You sound like a guy who's got stars in his eyes for high horsepower, The car sounds like someone's project that is not "done" and may not even be well-designed and executed. I wish I could find a GIF for Dirty Harry's "do you feel lucky" line. Shuddering at take-off is usually a clutch engagement problem. Maybe it's slipped a few too many times under all that power. Or the 1st gear ratio is too tall for the diff ratio. Lots of questions. Just buy it and start working on it. Who wants a car that's done anyway. -

Anybody have trouble installing polyurethane bushings?

NewZed replied to jparker893's topic in S30 Series - 240z, 260z, 280z

Is the wheel on the ground and weighted by the car? Looks like you have the wheel hanging. The rod might be at an angle. On the ground makes everything super-easy. Things are incredibly harder than would seem rational with the wheel hanging. .