NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

In Google Chrome on XP, all of the pictures show as broken (the cracked picture icon) on this thread - http://forums.hybrid...230-diff-mount/ Clicking on a picture link just gets the spinning wheel. The pictures used to show up fine on my system, in the thread and clicked open, before. But in this thread - ... small pictures in the thread blew up to a good size and looked fine when clicked on. Edit - Firefox and IE8 give similar results to Chrome.

-

The S65 is a V8, apparently. Shouldn't it sound like the SBC V8?

-

If you followed the atlanticz write-up for the alternator swap then the brake check warning lamp relay under the passenger seat is probably on all the time. You can cut the yellow wire to the relay and splice it in to your fuel pump circuit to power the relay, if you want the light to work, otherwise you can just cut the wire and tape the ends. I have a 76 and I had the same problem after converting to the newer regulator setup. If I recall, the yellow wire is tapped in to the same wire that S uses so it's a direct connection to the battery. Check the wiring diagram first and check the wires for power to be sure, before you take a chance on my memory. I think it's described in Body Electrical in the FSM.

-

Alternators can cause a short, either through a failed component or just dirt and carbon creating a conductive path to ground. Disconnecting the wires is a simple test. Disconnect all of them, S, L, and battery. If it's the problem check the condenser/capacitor connected to the B+ wire before replacing the alternator. The same thoughts apply to the starter, lots of exposed positive connections and possible short paths.

-

Looks right, except that you've left off the very important ground circuit through the mounting hole. One of the holes will have a wider metal rim for good grounding. Make sure the mounting point is grounded or run a separate ground wire. Don't forget to disconnect the original module and tape up the wire ends since they'll be hot with the ignition on.

-

Engine cranks, but won't start. (No Spark)

NewZed replied to TheCrazySwede's topic in Trouble Shooting / General Engine

Your car has electronic ignition. The problem could be the ignition module, the pickup coil in the distributor, power supply to ignition system, mechanical (is the distributor rotor turning), etc. The Electrical chapter of the FSM does give a good detailed description of how it works and what to check. Instead of using the 1977 FSM, download the 1976 files and open the EL chapter, the 1977 internet FSM is the whole thing in one file and hard to get through. 1977 and 1976 used the same setup, things changed in 1978. Since you have a meter, turn the key on and check for battery voltage on both terminals of the coil, negative and positive, with all wires attached. -

Connect a wire to connection on the solenoid where the smaller black wire is (pull the black wire off first) in your first picture, then touch it to the battery positive terminal. If the starter turns correctly, the problem is in your wiring. If it doesn't, the problem is with the starter, solenoid or engine. Make sure that the car is not in gear and that you're ready for the engine to turn over. There will be a spark at the battery terminal. Or just jump it at your board. But first, make sure that your battery connections are clean and tight. One turn then a bunch of clicks is typical of dirty or loose connections. Plus the fact that you're losing power to the board, which appears to be connected directly to the battery. How can you lose power to the board without losing the battery connection? Looking at your what you're doing with the wiring and board, you might have already tried this but sometimes the obvious is overlooked. Where did you get the terminal board? I was looking for something similar recently and they're selection around here is slim.

-

260z L28et Build (first build newb)

NewZed replied to Co0ke's topic in S30 Series - 240z, 260z, 280z

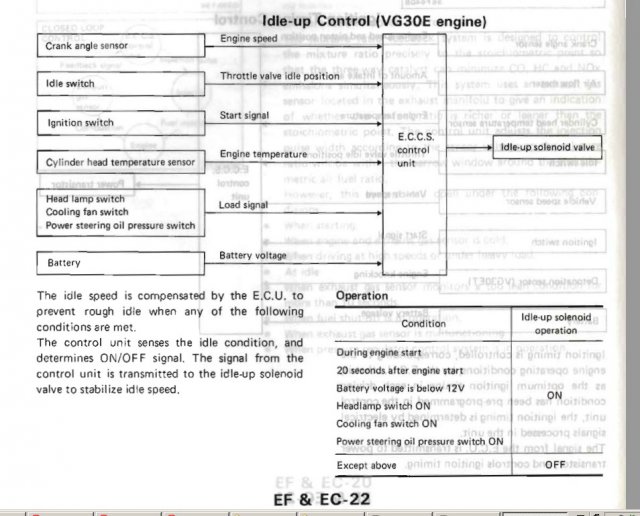

Just trying to tease out the details. The main VG30 ECU swap that's pinned in the FAQs is for the 1984 300ZX. Sounds like the M30 ECU is more advanced, so your swap might be better. http://forums.hybridz.org/index.php/topic/26230-z31300zx-ecumaf-to-280zxt-swap-guide/ The M30 ECU uses the O2 sensor for idle control? Then your comment about improved idle within minutes makes more sense. Sounds like it might be a good swap even for a simple stock NA 1976 EFI setup, like mine. Is the O2 sensor for the M30 narrow or wideband? (Never mind, I see from the web that the wideband wasn't even developed until 1994). Not to thread-jack, but the OP could probably use the information also, just for options. Edit - Found my answer about the better idle. The ECU controls idle based on RPM, but doesn't use the O2. Still much improved over the early EFI ECUs. Assuming that the 1989 system is similar to the M30. Here's a diagram from the 89 300ZX FSM. Edit 2 - Of course, you probably don't have an idle-up valve on your L6. Still wondering...who knows, maybe there's a timing advance algorithm in the ECCS to control idle also. -

260z L28et Build (first build newb)

NewZed replied to Co0ke's topic in S30 Series - 240z, 260z, 280z

Hate to be picky, but I'm pretty sure that the early Z31 ECU's don't "learn". They don't record engine parameters for future use and have a new "tune" ready when the engine is started. I think that they only store engine fault codes. They do self-trim "on-the-fly" as the engine is running via sensor inputs like the O2 sensor and they do some self-maintenance like burning off the MAF wires, but I can't find anything that says there is any kind of programming incorporated that records "knowledge" of the engine and saves a new file for operating the engine. Every engine start is from scratch, I believe, and the self-trimming begins new every time. Resetting the ECU doesn't lose anything but fault codes. I might be wrong but that's what I get out of the various descriptions of how they work, that I can find. Could be semantics but compared to the Nistune, which can store a user-specified startup file and default file (as I understand it) for when sensor parameters might be out of range (WOT, for example) it might matter for the conversation. I bring it up because the FSM implies that default values are used at idle. The O2 sensor isn't even used. The engine idle parameters should be the same every time the engine is started. What you noticed may have just been from the engine warming up or the MAF wires getting cleaned or the O2 sensor drying out or some other new parts thing (no offense). -

That's where the antenna switch is on my car, 1976. Mine is a factory-installed (as far as I can tell) spring-loaded momentary switch though, not an on-off.

-

The alarm might have been used to activate a relay which may still be in the starter circuit. You'll probably just have to trace the wire from switch to starter. If someone has messed with the wiring to install the alarm, no person or FSM diagram is going to be able tell you where to look to fix the problem, because there's no way to know what the installer did. You could just run a new wire. Get the wiring diagram and run new wires to the appropriate places. You'll probably find the problem while you're doing that.

-

260z L28et Build (first build newb)

NewZed replied to Co0ke's topic in S30 Series - 240z, 260z, 280z

What kind of engineering do you teach? -

The guy in your link is talking about modifying the timing advance curves. The distributor will "work", triggering spark from the coil, but it may not be optimum, depending on how you want the engine to run.

-

There's quite a bit of information out there on using the GM HEI module. Search the words on the internet and you'll find it. If you have original wiring you might find a specific write-up for your car, or you can figure out what the various pieces do and go from there. There are only five connections on the module to worry about, the four pins and the ground. You'll have to do the same with the ZX module, but three of the circuits are already connected internally for that one. You can use the GM module on the ZX distributor also, by removing the stock E12-80 box and rewiring. If I had those two distributors and both were used, the first thing I would do is take them apart and see which one is in the best mechanical condition. Most of the old distributors are pretty well corroded inside by now. Might make your choice for you.

-

Looks like diode testing. Put your meter in diode mode ->| and test as shown, positive on g, negative on a = no continuity, negative on g, pos. on a = continuity. My meter beeps for continuity and shows a value in volts (I don't really know what the value means though). Go down the rows g/a, g/b etc., then g/1, g/2... Looks like 36 tests. One bad value and you're N.G. I'm no electronics guy but I was just messing with some alternator diodes earlier today and had to figure out the +/- continuity thing for testing.

-

One sounds like a ZX distributor, or Maxima, the other like a 75-78 280Z. The centrifugal and vacuum advance curves are most likely different from each other and both different from a typical, early, carb'ed engine's stock distributor. The total centrifugal advance will be stamped on the weights (under the breaker plate) but you won't know which springs you have, so won't know when it starts and when it's all-in. If they have blue wires, they're probably rebuilt so will have a "rebuilt" vacuum advance canister, of unknown characteristics (I think that the rebuilders use conservative specs. to avoid blowing up engines). There's really not much you can tell just by looking. Neither is probably ideal for your engine, but both will probably work. The 280Z dist. might be better since the ZX distributors were designed to run engines with lots of emissions controls. But the ZX distributor already has an ignition module (one reason the ZX distributor is popular, because it's easy to plug in and go if swapping from points), you'll need to get one for the 280Z distributor (the GM HEI module will work well and is cheap).

-

brake calipers not properly working

NewZed replied to Danochumongs's topic in S30 Series - 240z, 260z, 280z

One down. OReilly Auto is not known for the high quality of the parts they sell. Take the MC back and get a refund or get another and try again. The pedal can't go to the floor unless the seals stop sealing, therefore... Throw a few capital letters and some punctuation in to your posts also, it will improve your thought processes and make these types of problems much easier to solve. It's like exercise for the brain. (edited for mellowness). -

More amps (amperes, not amplifiers).

-

brake calipers not properly working

NewZed replied to Danochumongs's topic in S30 Series - 240z, 260z, 280z

The pedal slams to the floor because, probably, your master cylinder seals are blown. Was the "new" MC old? Corrosion happens and will destroy the seals. The brake light goes on if there's a pressure differential between front and back. There might still be a big air bubble in your lines. Check that the bleed valve for the calipers is on top, not on the bottom. The calipers are reversible. -

That Dirty Jobs guy is everywhere.

-

PCV tube. You don't want any coolant going in there.

-

Did you measure voltage at the starter or are you assuming there's no power because it doesn't turn? There's a lot of basics missing here, like the battery's charge level, condition of the battery posts, any actual voltage measurements, etc. Sounds like you just have a dead battery or dirty terminals.

-

The part that's not clear is what you mean when you say the pump doesn't work. If the pump turns, then the problem is most likely not electrical. But you're theorizing, above, about blocked fuel lines which implies that the pump is turning but no fuel is flowing. In your first post you said that the pump hasn't "fired" since you parked the car. What does "fired" mean? You said that the ground is connected, but you didn't say that you confirmed it's actually grounded, electrically. If you have 12 volts at the positive terminal, take a separate jumper or piece of wire and make sure that the negative terminal is grounded back to the battery. If the pump doesn't turn, don't worry about blocked fuel lines. You'll have to listen to the pump to find out if the pump is turning, or measure the voltage drop across the terminals like Domzs suggested. Listening is easier.

-

transmissions that work with our engines

NewZed replied to Rusty Bomb's topic in Gen I & II Chevy V8 Tech Board

Might get better information from a Chevy V8 forum.