NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

Everything in 35 looks right. You didn't show that you have a good grounding of the case though. And you didn't show the values with the engine running. But the measurements shown look correct.Not sure what's happening.

-

There doesn't seem to be much point except confirming that it started life as an L28. You know that "stoker" means the crankshaft has been replaced with a longer stroke crankshaft, right? Often bored over-size too, to increase displacement even more. And pistons replaced. Unless you're actually trying to say that you got a spare engine with the car which makes the striker stuff irrelevant. The N42 block was used in 1979 ZX's.. Maybe some 1980's (not sure, 80 seems to be a transition year for other parts too, ,like transmissions), before they switched to the F54. Beside that, a matching transmission doesn't tell you where the engine started life. I've had four different transmissions and two engines in my car. They mix and match.

-

Apply power and confirm pressure. Isolate.

-

Since you did say earlier that you saw battery voltage at the bottom leg of the T plug and everything else looks good here's something that happened to me a few years ago - the T plug connector was loose and dirty. It wasn't making electrical contact. I found that I could wiggle it to a new spot and the alternator would start charging again. It was an odd thing. A quick squeeze with some needle-nose pliers fixed it. Make sure the T plug is making good contact with the alternator terminals.

-

And all of your measurements in Post #25 look correct. Your comment in #26 doesn't fit what you saw. Everything looks fine. BUT. You didn't show the measurements at the T plug.

-

It seems to me, based on the way you're writing, that you might not really understand how to measure voltage. No offense. But your word usage is not the way a person experienced in these things would write. Voltage is not gotten. It just exists across points in a potential circuit. " earth on the alternator is getting 12v from the positive on the battery". It looks like you put one probe on E and the other on the battery positive terminal and saw 12. That would be a correct reading for proper wiring.

-

Are you sure that there is continuity to the battery positive post from the alternator's charging wire, the BAT terminal? Follow the path. You can test if it's charging by measuring between the BAT terminal and ground, directly from the back of the alternator. You can test continuity by measuring battery voltage at the BAT terminal directly with the engine not running and key off. The BAT terminal is always connected to the battery positive post, normally. Did you check those fusible links yet? You might just stop, now that you've been working on this problem for a while, and think about how the system works, and what should be connected to what. Could be that you've been assuming that the charge wire is connected to the battery, but it's not.

-

Seems like the only information you might get would be if it's flat-tops or dished, or if it's a turbo block or not. But since it's a stroker, the crankshaft and pistons have been out so the first is irrelevant. The second might be knowable, but that number is lower than my 1976 number 71155 so, if it is an L28 it's probably a 75 or 76 N42 block. Nissan put the engine number on the ID plate by the strut tower, up to about 76-77.

-

We've overlooked one of the basics of most Z and ZX alternators, especially the parts store remans - they don't put out much current at low RPM. Did you rev the engine and check voltage? If you have battery voltage at the L terminal (the bottom of the T) the alternator should charge if it's spinning and nothing is drawing it down. Your battery is getting low, 12.4 means it at about 70% and needs a charge, and it might be drawing all of the current if you're doing your voltage checks at idle RPM. If you give it a rev and it still doesn't charge, have it checked at a parts store. Parts store remans aren't known for high quality, generally. Your wiring seems right. It should work.

-

That's the condenser. And the charging wire (withe with red stripe). The battery cable is the one that goes from the battery to the start lug. It's big and thick. Like a cable. Just connect it like it's shown in the picture. To the BAT terminal. The wire end of the condenser connects to positive, the body to Earth/ground. E. It is there to absorb electrical noise. Don't leave the blue wire coming out of the harness disconnected because it might short to ground. Hopefully it hasn't already. Check your fusible links while you're in the engine bay. To be sure you didn't short something and blow a link.

-

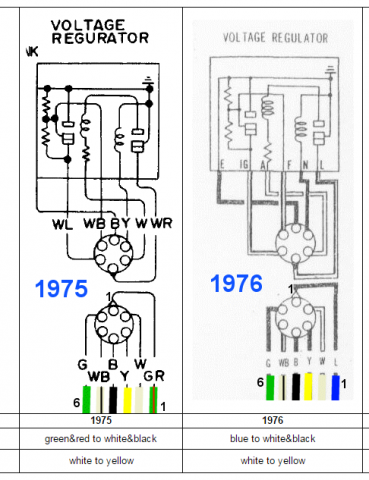

1975 doesn't show a blue wire but 1976 does. Use your meter to find the switched power wire. You might have 76 colors in your 75. Nissan changed things on the fly sometimes. And what does "battery connector for the alternator" mean? Doesn't paint a picture.

-

The wire connects to the thick charging wire. You should always check your work with a meter if you can. It will save you a lot of time. If you don't have battery voltage at the T plug with the key on, work back in the wiring until you find the problem. The 1975 wiring diagrams will help you also. The Engine Electrical chapter has small specific diagrams so you don't have to use the big one.

-

If L doesn't get power with the key on the alternator won't charge. Do you have a meter? Is your ammeter connected? Have you had the car long? Did the old external regulator system work? Why did you decide to do the swap? Is the alternator body grounded? The thing is called a condenser. The body is grounded and the wire is connected to the main charging wire.

-

What is this bracket by the diff strap for - 1973 240Z

NewZed replied to GIchiro's topic in S30 Series - 240z, 260z, 280z

The twisted piece with the hole in it looks non-stock. You might edit your title to something descriptive like "What is this bracket by the diff strap for - 1973 240Z:". -

Which one? Provide a link.

-

Sounds like you used a short TOB collar with a newer short pressure plate. Any 225mm pressure plate from 70 - 83 will bolt on to your flywheel. Who knows what the spring/lever height is... Look at Post 23. With all of the possibilities out there if you don't measure you have to get lucky.

-

Your Google-fu is strong. What's your objective? Derek did some good stuff with ITB's and EFI. Search his posts and you will be closer to the grasshopper..

-

Your questions are a decent step in to the world of EFI but yes, they are a bit odd. A great starting point to learn about EFI is the Engine Fuel chapter of the 1975-1978 FSM's. They give a very fundamental explanation of EFI because they were the first years of EFI for Nissan. Seriosuly, download the 1976 FSM and read the Engine Fuel chapter. On spark, there are many possibilities, but much of the very complex systems are really designed for emissions purposes, not performance. The performance benefit to cost ratio isn't great for anyhting beyond a fairly modern electronic igntion system. The Pertronix system is an early electronic system that has survived the years, But there are simpler, chepaer ways to get a good stronger spark. ZX distributors, GM HEI modules, MSD setups, etc. If you want to make a big jump in to EFI, read up on Megasquirt. The Megamanual is random and complex but there are some good writeups on different manufacturers' systems that can be very educational. But you can get lost in there too. Keep reading and posting focused questions and a path will show itself. Good luck.

-

I suggest reviewing the suggestions in this thread, addressing the potential causes, refocusing, and providing better information. You got a bunch of ideas from your video but now you're saying the video is old. All those people who watched the old video, wrote some numbers down,and did some math for you. Are they going to do it again? Who knows. Here's another possibility for you - tiny, or clogged boost hoses. Bad boost data. Or a bad boost gauge. I didn't watch the video (and won't now, because it's old) but if you're just shooting up in to boost zone and then back down, maybe there's a delay at your gauge. Several people are questioning your numbers, you should verify that you're getting good data. The fact that your pressure gauge company backs their products doesn't mean that they don't break. Just means they'll fix them when they do. Much of what your dealing with depends on good information. You have a lot of sketchy numbers here. Since the engine is safe, you can spend time making sure you have good data. Millions, maybe billions, of hours have been wasted by people working with bad data.

- 57 replies

-

- fpr

- fuel lines

-

(and 6 more)

Tagged with:

-

You said it runs great, doesn't smoke, no real problems except an AFR number (the LED's on the gauge - my joke) that makes you uncomfortable. But it's uncomfortable on the safe, rich, side. I didn't go through your math, but at least two people did and said that there's no great mismatch between fuel pressure and boost pressure. The numbers are right. Basically, it looks like you don't really have a problem to fix. And the only solution to fine-tuning your AFR's is to get a tuneable engine management system. There's nothing that can be done here. Stop looking at the AFR gauge and enjoy the car. Or get a tuneable system. That's all I'm saying.

- 57 replies

-

- fpr

- fuel lines

-

(and 6 more)

Tagged with:

-

Seems like your best option might be to just stop looking at the AFR gauge. You're tuning to an LED.

- 57 replies

-

- fpr

- fuel lines

-

(and 6 more)

Tagged with:

-

If I recall correctly, you can remove part of the bracket for the strut . It looks like it's welded but part of the bracket is bolted on and does come off and will give you more room to slip the panel out. It's a bracket bolted to a bracket. You'll need to prop up the hatch I think, since the end of one strut will be loose. I'm working from memory of past advice, and realizing how it worked later. I have tried to remove mine but changed my mind when I got stuck in the same spot. The part I was trying to get to became less important.

-

You're not really using the way a fuel pump works correctly. All it produces is volume. The FPR creates pressure. Assuming the same voltage, you'll get maximum volume at idle or engine not running. Because the injectors aren't bleeding off volume. Assuming the same voltage again, if the return line was a restriction, you'd see the problem when you were running the pump without the engine running because the volume would be the greatest. Nothing bleeding it off. I'd check your pressure with a mechanical gauge. Could be that you just have a rich tune on your JWT ECU, everything's fine with the FPR, and you just have a funky transducer on your pressure gauge. The one in your pictures. You might be on a wild goose chase, from bad data. Pretty common.

- 57 replies

-

- fpr

- fuel lines

-

(and 6 more)

Tagged with:

-

Just a flyer - are the reference port for the FPR and the port for the boost gauge in the same spot, or close? Just to be sure. The boost pressures is "helping" the regulator spring close the FPR return port. Hard to imagine a step-type increase in pressure, of 5 psi. The return line would only seem to come in to play if you were on the edge with the pump output and extra voltage caused more pump output. Maybe your voltage regulator is bad. Another flyer.

- 57 replies

-

- fpr

- fuel lines

-

(and 6 more)

Tagged with:

-

All lights are dim, brighten when I rev [UPDATE] Alternator not charging

NewZed replied to JTCN's topic in Miscellaneous Tech

1975 still has the Ammeter so your simplest quickest check of a failed VR is to put a meter on the battery terminals and rev the engine. If you get 16 or over, that's bad. The complete, thorough test procedure is shown in the FSM. Whatever path you choose, owning a good multimeter is almost mandatory for working on these cars. You can just go to the parts store and get a 1982 280ZX alternator and you'll be fine, if you decide to do the swap.- 8 replies

-

- battery

- interior lighting

-

(and 4 more)

Tagged with: