All Activity

- Past hour

-

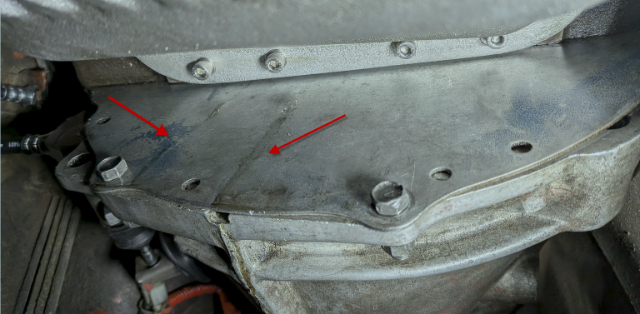

After priming the engine oil and starting/warming up the car, there is a small leak around the rear main seal. It is either my side seals or the rear main. Considering how easy it is to bump the seal while installing the rear cap, I wouldn't be surprised. I guess it is time for a tranny drop operation. I will check with my endoscope.

-

Hi CalZ, It is https://www.amayama.com/en

-

Cool stuff Clark! I dig the ARB. Cary

- Today

-

If i still had cruise on mine, i'd be happy to find out for you. But i don't have it no more. Props to you for thinking you need a cruise control unit that goes higher than 75. Good luck. Hope someone can help.

-

I'd take them off and have a close look. If the bleeder screws have holes through and the screws seal, then they MUST have an effect. If you can't measure a difference with the synchrometer, then there must already be an overwhelming amount of air going past the butterfly. Either they're already open, or they're poorly centered.

-

What is the name of the company selling brand new timing covers?

-

Back to synchronizing itbs . #4 reads less than #3 port . Bleeder screws do nothing on any ITB - are they just there for looks ? No blockage I can see anywhere . I can pull the needle completely out and it does nothing to change air flow . I thought previously it was #3 was hanging on the linkage but that turned out to not be the issue . If I got any adjustment out of the bleeder screws I think I could get it dead nuts . I’m at a loss . Been searching on line but with no luck . Maybe cheap Chinese stuff .

-

Aussie Speed has a dual SU intake for draw through turbo setups. This intake would also allow for dual Mikuni HSR bike carbs as well!

-

Lunar Loox joined the community

- Yesterday

-

So after much searching and an upgrade to 1.6 firmware I was able to control these fans very well . They must have some built in controller that can decipher the low PW signal from MS . Testing at 87hz -which is what MS3 offers - they worked smoothly with no humming or any strange behavior . My GOD they move some air . Still wish I knew how much CFM they really are . The 1.6 firmware allows for a low/partial speed and full speed . Haven’t tried any AC controls since I don’t have AC yet .

-

Does some one know how fast you can set the cruise on 280zx or a z31 300zx? by that I mean is there a limit to the speed it will allow you to engage cruise control? I have a 1984 maxima wagon and my cruise works fine except that by design it wont allow me to set cruise past 75mph. Is this limitation the same on the 280zx and the 300zx? I'm looking to swap in a cruise control module from the same era of car that doesn't limit the speed. Ive already looked at the wiring and the 280zx looks to be plug in. and a 300zx will have to be reworked but doable. Thanks in advance.

- Last week

-

WOW!! That is slick!! The car's coming along nicely! 👍👍

-

IMSA GTU vintage racer build

DuffyMahoney replied to clarkspeed's topic in S30 Series - 240z, 260z, 280z

man, how cool is that! -

Fast Floridian's 240Z Track Build

FastFloridian replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

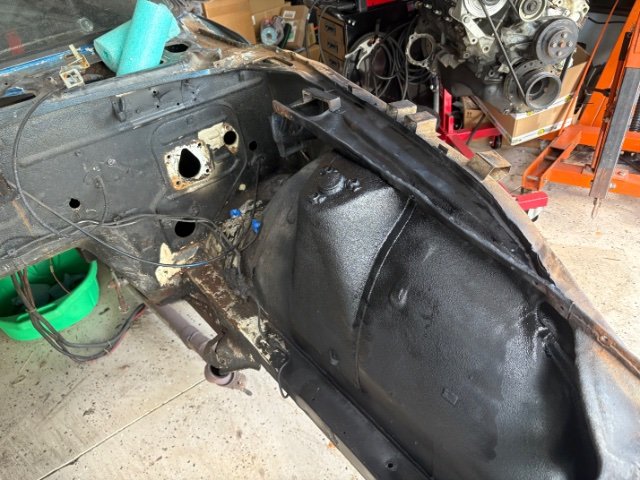

Got on the wire wheel and went to town on the engine bay and front fender wells, prepping for paint. Need to wash it down and go over it one more time. Test painted a few spots. Also got the fender braces on, but not fully welded. Started getting a hole in the body panel, so decided to tac it and fully welded it later after some more practice, probably start practicing tig, need some gas first. -

Fast Floridian's 240Z Track Build

FastFloridian replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

Going with a holley digital dash, this offered a blank canvas. -

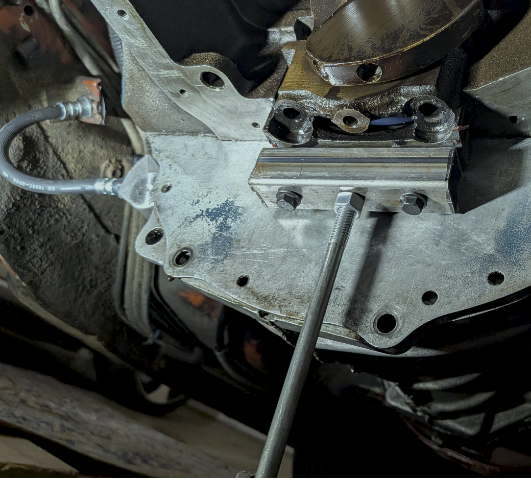

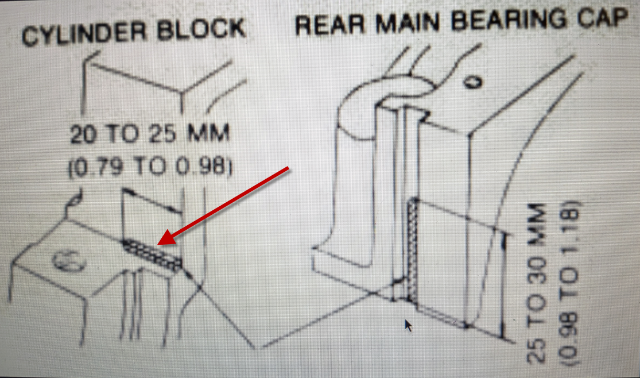

I have been dealing with some consistent oil leaks around tranny/engine block, and front RH lower part of the timing cover. The worst leaks would happen when the car was parked at an incline. I replaced my original TC with a new unit (there is a company selling them from Japan), total shipped was around $100. My original cover had some stripped threads. The water pump's long 80mm M6 bolt (at 10 o'clock) was broken inside the block. I had to weld a washer with a nut to remove it. The oil pan gasket that I sealed 10 years before, with permatex gray/gasket sandwich started leaking on the RH side. The removal of it was a major pain. I decided to get an aluminum pan from AZC since I am considering a turbo upgrade in the future and that pan already has provisions for the oil temp sensor and turbo oil return fitting (I went with the 8AN fitting). The pan is solid and straight. I 'glued' the cork oil pan gasket with the permatex black to the pan to prevent the gasket movement while I was installing the pan. My hope is the fact the pan is a solid aluminum piece, there is not going to be much flexing/worrying about dimpled surfaces etc. While the pan was off, I also replaced the rear main side seals. Mine looked old/brittle when I removed the rear main cap and inspected them. I tried pulling the metal inserts with a pair of needle nose pliers, but they were stuck really good. The rear cap was removed using an improvised slide hammer (the taped part is a bunch of heavy washers): It took about 10 minutes to remove the cap: I didn't see any sealant in the corners in my engine. I am hoping this might explain the oil leaks. Per FSM: Before the cap installation, I put a bead of gray ultra in the corners on each side. The side seals got a coat of gray as well when I inserted them. The rear main cap was in a freezer. Its installation went smoothly. I haven't filled the engine with oil/coolant yet. If I see more of oil leaks around the rear part of the engine/tranny, I would probably pull the transmission and replace the rear main seal along with the transmission's gasket/seals.

-

Fast Floridian's 240Z Track Build

A to Z replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

sure is a different looking dash! -

My Z car log....small jobs done and fun things

A to Z replied to A to Z's topic in S30 Series - 240z, 260z, 280z

08-02-2025. My thermostat probe arrived, and after a bit of thread sealer I installed it and crimped on the end to finish that job. then I FINALLY got my new speedo cable screwed on to the back of the speedo. IT WORKS! In testing out my fan, I took 3 pictures of my gauge you see below. The first one is where the fans turned on, between the "M" and "P" on the word "TEMP". The second is what the fans pulled it down to , and the third page is where the fans turned off when I had turned the engine off and the fans were running....when they stopped I ran and took this pic, so don't fret about the oil psi looking low as the engine was off! I also have 3 videos at the end of the pics, just walk around type pics. So I can really say it's done. I did the car twice before this, and then the turbo install which turned into a MAJOR undertaking. Was it worth it? Yeah, but I didn't know how deep the rabbit hole was going to be when I started.....if I had I may not have done it, but what is done is done. With a draw through turbo setup like this, you have to have an "educated" foot, gradual on the adding power and removing power unless you are over 3000 RPM. That is the way these are, or at least the way mine turned out. I know the instances where it will go lean for about 1-2 seconds in certain accelerating situations, and hitting the Water/Meth injection right then smoothes that out. I think a small block Chevy (with dual 4 barrels & a nice cam) would have been way easier than all this, but maybe keeping this an L series makes the car more "neat", I don't know. Anyway this my Z car, version 2.5 V1.MOV V2.MOV V3.MOV -

I found this You Tube Video that shows the use of Laser Technology to strip down a Fairlady in Japan. Although the video doe not have English Subtitles, the Laser Machines utilized provided a different method of removing paint, rust, corrosion,etc. The major drawback is it is too labor intensive. Using Total Chemical Vehicle Dip (previously shown) would be much faster and still be able to remove internal corrosion (in boxed areas). But in certain case such as surface corrosion, this method would work well. I found the video interesting as it provide a new option in corrosion and paint removal in the restoration process.

-

-

Haltech Elite 2500 ECU mapping for RB25DET in NSP

Jcmclaughlin81 replied to sixstarlegacy's topic in Nissan RB Forum

It's not a straight forward plug and play for any car. You have to set your TDC offset angle before it will start up. It's easy to do and there's a write up on how to do it on Haltech's site. https://support.haltech.com/portal/en/kb/articles/calibrating-ignition-timing-7-4-2020 -

By "tightened up" do you mean you just cranked down on the nut? If your front bearings need to be replaced that's one thing, but you should definitely not just tighten them down. Did you follow the FSM procedures for proper torque on the front hubs? It's way less than you would expect. The nut gets torqued to 20ft lbs then *backed off by 60 degrees. I had a front wheel bearing fail pretty catastrophically last summer and the race bored out the hub. Most likely cause was that it was just too tight. initially and failed prematurely then seized suddenly and basically friction welded itself.

- 15 replies

-

- 1

-

-

The reason for replacing them is not for quality, its for fitment. I'm pretty sure Viking offers a coilover long enough to fit with my SLA design but I know the Penske one will work. I just need to check for interference in the UCA throughout travel. Lol well if you wanna save a few pennies on the front kit from AE let me know, I'm going to get rid of mine. That last part is probably true, but more tie rod ends means more maintenance and more failure modes. Dirt and debris entering the ball joint and load fatigue both contribute to this. I've spoke to Viking and they were very helpful. A little confused on the choice to use the C203 shock with the motion ratios given to me by Apex. From their reaction and the assessments from Rob Fuller and Mike Maier I'm standing by my opinion that 3.2" of shock travel is simply not enough.

-

Their overall suspension including the front to me is good. It has evolved to the current version which has been updated at least a couple of times. Instead of trying to design your own you might consider just upgrading the Viking to the quad adjustable which is what I am doing. The Viking with their front can work great but you just have to be sure to know roughly what height you want, the tire/wheel height, etc. To me it is not a limitation on travel but they just have a limitation on the range of changing the ride height but once you know the desired midpoint that is a mute issue. I am getting their current Track Attack but am ordering them with the upgraded Viking 4 way adjustable Berserker coil overs so that I can get the ability to please my wife when not racing and high speed settings when needed with their independent high and low speed rebound and compression system. Once you know your desired midpoint then the Viking will give you around 3 to 3.5" up and down height adjustment which is plenty and your not likely going to change once you find your ideal level. Many big HP Corvettes, and other street/track cars are very happy with the Viking Quad coil overs. The Apex extra settings to me do not make it weaker but rather just complicate it for owners as those settings would never ever be used so you are just creating more chances for DIY people to get frustrated. Also as Ben280 suggested Viking tech support is very knowledgeable and can help you choose the right version. Again I do not believe there is any issue of bottoming or travel limits. It is just that the Viking gives you plenty of adjustability but the design is not a standard nono tube coil over so you just need to know the mid point of the height you want the car to be and order the right length to match. It is all of their adjustability which creates this difference compare to a mono tube where you do not have all of those knobs to adjust things.

-

heymister442 joined the community

-

Center bolt valve covers - what heads?

heymister442 replied to RPMS's topic in Gen I & II Chevy V8 Tech Board

Did you ever find out what the FSX was? I have one and cannot find anything on it. -

I see, it seems AE just sent me 4 identical C203 shocks from Viking and said have at it. I won't be using them anyway, the entire front suspension kit is pretty much a wash for me at this point. Going to just resell it for cheap once I finish my own design. I'll be either using JRi modular shocks that are 21.7" extended or Penske 24.7" extended. I agree, there's too much usage of many tie rod ends, from an engineering perspective it just adds more and more failure modes, more and more maintenance. I'll edit this post and link my front SLA thread.

-

Who's Online 5 Members, 0 Anonymous, 567 Guests (See full list)

.jpg.b34f27553f5960421801c8ab2cbf5db3.thumb.jpg.7889e8073010b6a0d8d6aae0626e768b.jpg)