-

Posts

2391 -

Joined

-

Last visited

-

Days Won

35

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Miles

-

As of 9/21/2011 Air Brake Repair Service Inc. dba Power Brake Sales 1517 McCormick St. Sacramento, Ca 95811 800-624-8185 916-446-7829 www.powerbrakes.com They had all of the parts to rebuild the booster in stock. Took less than a week. Cost to rebuild 280Z booster: $120.63 I bought the 1977 280Z booster at a wrecking yard for $50.00. Nisson Only wreckers 3561 Recycle Road Rancho Cordova, Ca 95742 916-631-8333 As I recall I used the 1977 280Z booster because the push rod matched the brake pedal clevis of the 240Z better than other year 280Z boosters. The treads of the 280Z booster push rod matched the 240Z brake pedal clevis. There is a thread in the brake section on this subject.

-

Lesson learned the hard way. I bought a V8 swapped 240Z in 2000 thinking that the with the basic swap complete it would save some time and cost. It didn't. Had to dismantle the car and reinstall everything the PO had done. Real horror show once I got into it. My second 240Z V8 project started with a well maintained completely stock two owner 72 240Z. Much easier to start from scratch not having to correct mistakes and poor craftsmanship made by the PO.

-

Agree with Seattlejester. It is an average build. Also, what is the quality of the build? Craftsman-like or a hack job?

-

I was going to use the Painless kit for one of my 240Z cars because the PO chopped up the engine bay wiring, but ended up just re-doing the stock wiring. Many many HybridZ write ups on the Painless and EZ kits installation. Some are very detailed and include directions on how to interface the kits to the turn signal and head light switch. Search "Painless" "EZ Kit" etc.

-

I'll try again in 24 hrs.

-

For the last three days clicking on "View New Content" results in this response: Sorry, no new content found.

-

Do all of the bushings with polyurethane except the T/C rod. Use stock rubber bushings for the T/C rod. Other than the T/C rod do not mix rubber and poly bushings. Search the suspension forum if you need to know why. I did mine over ten years ago along with Tokico blue struts and Arizona Z Car springs (front 180lb/in, rear 200lb/in). Car with SBC 350 sits at stock ride height. Car is very stable on the street and in the mountains. My poly bushings have never made any noise and the car is very comfortable in traffic and long road trips. Suggest you search the suspension forum for more info and installation instructions. Many many threads to look at. Ignore all of the drama about noise and harsh rides - most of it is subjective and/or hearsay.

- 33 replies

-

Disconnected everything, removed shifter and cut exhaust at the header with a saws-all. The leveler makes it easy.

-

Do you know what the dampening rod does?

-

Addressing firewall flex

Miles replied to grannyknot's topic in Brakes, Wheels, Suspension and Chassis

Not for firewall flex. For strut tower movement. Anything attached to the strut tower (such as a device to arrest master cylinder movement) will also move. -

Addressing firewall flex

Miles replied to grannyknot's topic in Brakes, Wheels, Suspension and Chassis

Strut tower braces to the firewall might do the trick. I noticed that going from a 240Z booster to a 280Z booster reduced firewall flex somewhat. -

-

240z S12W+280zx disc conversion

Miles replied to superduner's topic in Brakes, Wheels, Suspension and Chassis

ditto Superduner ^ ^ ^ I am very happy with my brake setup: Toyota solid front, 240SX rear, 1 inch Wilwood MC, 280Z booster and Axxis Ultra brake pads (good cold bite). The brakes feel like factory and require very little pedal pressure which was not the case with a stock 240Z booster - 1 inch MC combination. With the stock 240Z booster the pedal was very stiff. Brakes work well in traffic and mountain driving. -

240z S12W+280zx disc conversion

Miles replied to superduner's topic in Brakes, Wheels, Suspension and Chassis

I am the Mythbuster you seek.................. I own two 1972 240Zs with SBC 350 and Camaro T5 manual transmissions. A 280zx booster will not fit on these cars because I tried it. If someone has installed a 280ZX booster on a 240Z configured like mine I would like to know about it and how it was accomplished. The picture I posted above of the 280Z booster in a 240Z with manual transmission is my car. Note that the 280Z booster fills the available space between the throttle pivot and the clutch MC. -

240z S12W+280zx disc conversion

Miles replied to superduner's topic in Brakes, Wheels, Suspension and Chassis

See post #17 above: The larger 280ZX booster fits automatic 240Z cars because there is no clutch MC in the way. -

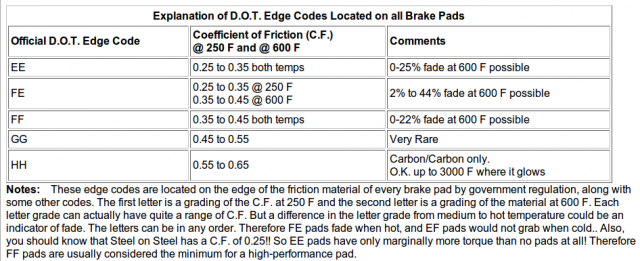

Other overlooked brake pad information is the FMSI code: Friction Materials Standards Institute (FMSI) is an association that assigns numbers to different pad shapes that are used as a guideline for pad manufacturers to refer to, and bring a common numbering system to the brake pad aftermarket. Every pad manufacturer will either use the FMSI number in their numbering system or have a readily available interchange to cross-reference their part number to the FMSI number. FMSI provides a standardized part numbering system for brake pad configuration for each manufacturer. For example: 1979 Toyota 4x4 pickup front brake pad FMSI code is D137 1989 Nissan 240SX rear brake pad code is FMSI D272 A Google search for FMSI pad D137 will list the pads shown in the attached picture. The FMSI number is in the lower right corner and is cross referenced to the other codes shown in the diagram. The FMSI code is handy to use when searching for brake pads

-

Steel hose barb to AN fitting

Miles replied to grannyknot's topic in Trouble Shooting / General Engine

I changed the link above from Summit to Holley. Also here is the Holley Earl's page. https://www.holley.com/brands/earls/ Or you can plug the Earls p/n 165056ERL into Google -

Steel hose barb to AN fitting

Miles replied to grannyknot's topic in Trouble Shooting / General Engine

Edit: 2:43pm 12/18 16 using a different link If you mean adapt to 5/16 fuel line then this will work: https://www.holley.com/products/plumbing_an_fittings_and_hose/adapters/special_purpose_adapters/parts/165056ERL -

240z S12W+280zx disc conversion

Miles replied to superduner's topic in Brakes, Wheels, Suspension and Chassis

Information about friction codes: http://www.bimmerfest.com/forums/showthread.php?t=570124 Brake bias: http://www.stoptech.com/technical-support/technical-white-papers/white-paper---brake-bias-and-performance-why-brake-balance-matters -

Move to California.

- 11 replies

-

- 1

-

-

- Compression

- oil pan heater

-

(and 1 more)

Tagged with:

-

240z S12W+280zx disc conversion

Miles replied to superduner's topic in Brakes, Wheels, Suspension and Chassis

The constraint for larger boosters on the 240Z is the space between the throttle pivot bracket and the clutch slave on manual transmissions cars. The larger 280ZX booster fits automatic 240Z cars because there is no clutch MC in the way. I used the 8.5 inch 280Z booster. See picture for fitment. The 280Z booster bolt pattern differs slightly from the 240Z which requires re-drilling the mounting holes in the firewall. On SBC V8 with T5 transmission equipped 240Zs you can to get a little more clearance between the throttle pivot bracket and the clutch slave by using Wilwood clutch MC instead of the Tilton clutch MC. The Wilwood clutch MC is much more compact. -

240z S12W+280zx disc conversion

Miles replied to superduner's topic in Brakes, Wheels, Suspension and Chassis

Originally I installed a 280ZX 15/16 MC with a 240z booster. The pedal was heavy and stiff with this combo. When the 15/16 MC failed I decided to try a 280Z booster with a Wilwood 1 inch MC. The 280Z booster made the pedal feel more normal and less stiff. Actually the 1/2" travel is the slack adjustment in the pedal, but the pedal feedback is immediate. Note: the booster was a tight fit between the throttle pivot and the Tilton clutch MC. When I replaced my clutch last year I used a Wilwood clutch MC which is more compact and just clears the booster. I would have preferred a 10" booster, but there isn't enough space. I'll post a picture of the booster later. swap info: http://forums.hybridz.org/topic/49295-260z280z-booster-in-a-240z-it-can-be-done/ -

240z S12W+280zx disc conversion

Miles replied to superduner's topic in Brakes, Wheels, Suspension and Chassis

Seattlejester I have considered trying a more aggressive pad with the 240SX rear calipers, but avoided doing that because of how road conditions change in daily driving. Also, my experience with performance pads is that they feel like blocks of wood until they heat up - again the need for cold bite in traffic. I spent several months researching brake pads with a higher "cold coefficient of friction", but found none for a 240SX caliper. The Bimmer/Vett people have more friction code choices EE, FF, GG etc pads. See atch picture for DOT friction codes. With my current set up Toyota solid - 240SX, 1 inch Wilwood MC and 280Z booster pedal travel is about 1/2" to engage brakes with a light/normal feel on the pedal. I had the280Z booster rebuilt by a company in Sacramento that rebuilds boosters and master cylinders. -

240z S12W+280zx disc conversion

Miles replied to superduner's topic in Brakes, Wheels, Suspension and Chassis

Grannyknot I have a test area that I marked off in 100' increments in the 70s. It is where I bed in pads and "test" my brake work. When I bought my two 240Zs in 2001 I replaced all of the brake components with OEM parts and drove the cars for several years before trying different brake setups. My biggest complaint with the stock brakes was fading in stop and go traffic and having to adjust the rear drums. Fading was never an issue with any of the Toyota - 240SX set ups I installed. None of the above setups hauled the car down faster then the stock brakes or would throw you into the straps. The advantage of these swaps, from my experience, is I have seen no brake fade and they have been low maintenance once dialed in. For track use several members report good results using more aggressive pads in the rear in conjunction with PV adjustments during the race. For daily driving the above brake swaps are ok. The problem with all of these brake modifications is there is no one place that records comparative brake performance data for popular Z car brake swaps. Developing comparative data has been brought up many times here and other Z websites, but has not happened. So you are left with trusting what others say or doing your own tests. Consequently, it is not unusual to find in old posts members going through several brake swaps until they get the performance they seek. -

Download a copy of the Factory Service Manual (FSM) for a 280ZX and you will know why the fuel pump isn't running. You will also learn where all the wires go.