-

Posts

397 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by z240

-

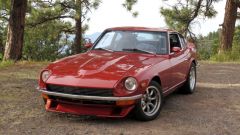

From the album: zkars

-

I captured the Racer Brown on-line article as a pdf attachment to help it live longer and be easier to find. RacerBrown_cam_bible.pdf

-

Careful!! 77-78 door panels are quite different from earlier 280/260 panels! The back edge is at a different (sharper) angle and the lock button in farther from the back edge. 260 panels definitely won't fit. There have been several discussions about this recently on classiczcar.

-

ebay engine mounts are available pretty cheap. Even found them with google (PN A2401) on www.autopartswarehouse.com for $17 bucks each. Beware however, I have found on some "aftermarket" mounts that the locating pins to be a bit too big and need to be filed down, and the two mounting nuts are not 8 x.1.25 but 5/16 x 11 SAE (whatever TPI coarse 5/16 bolts are). The chassis stud was 10 x 1.25 as expected.

-

I have what you crave. A Nismo LSD with 3:54 already in a long nose R200. And close enough (Calgary) that shipping won't be a silly expensive. Drop me a note to z240@shaw.ca and we'll work out the details. Jim

-

I recently experienced the same issue while changing both rear bearing sets. I have MM's inner CV flange with stock stub axles. One side went together "normal" with expected preload reached at ~200 ft/lbs, but the other side got real tight real quick as I just began applying torque on the nut. Took it all apart, cleaned it all very thoroughly, re-cleaned the bearing seats in the housing, re-greased everything and re-set the seal carefully, and it went together and torqued up normally this time, just like the other side. Wouldn't take much "error" in something to cause a bind. Clearly having that spacer in the middle missing would cause havoc.

-

-

The best BRE fitting and constructed spoiler comes from BRE. http://www.bre2.net/mm5/merchant.mvc?Screen=CTGY&Store_Code=B&Category_Code=bre_datsun_body_parts A very reasonable $145 bucks I think. Also note they have 240 and 260/80 spooks for a proper fit.

-

No worries about bolts that fully threaded. They do the same thing. As for length, you could just measure the thickness of the thermostat housing with a ruler at the two bolt holes, and add 5/8 inch for thread length into the block. That's 2 bolt diameters additional length (8mm x 2 = 16mm =~ 5/8 inch.) which is about what you need for good grip in the head. The bolts are 8mm x 1.25 thread pitch if your wondering that too. Happy bolt shopping!

-

Jimmy: I'm digging your throttle cable routing and mounting ingenuity. Simple, direct, functional, reliable. Brilliant.

-

Hazard switch for sure. Contact set in hazard sw that pass thru to the rear TS when hazards are not on (G and GY pairs) are bad. Hazard switch pull knob (73 specific) removal is push and turn to remove I believe. Then you have a nut to spin off with a pin/awl type tool. You can get your hand up behind to disconnect the two connectors that are attached. Straight from below the switch. Hazard flasher and TS flasher are separate. Switch can be disassembled and contacts cleaned. You can do it! Worst comes to worst, I have a spare.... Jim

-

If on-car, use big 24" bar-o-steel (2" angle will do) with two 1/2 holes drilled at wheel stud spacing. Bolt to hub, other end on ground. Add 24" pipe to 1/2 drive torque wrench handle to tighten said stub nut. With car up in air on jack stands, this degree of torque application can move the car, be careful... If on bench, put that angle iron attached to hub in a big vise or C-clamp it to the bench and torque away. Have 5 friends stand on bench if not a big bench.

-

Installed new mustache bar, now whining?

z240 replied to Indey's topic in S30 Series - 240z, 260z, 280z

Ah the joy of solid mounted suspension and driveline components and poly bushings. They always expound on the improved handling and bling factor, but neglect to mention the part about there being just the slightest bit extra noise for all to enjoy, like diff whine, bearing noise, u-joint and spline play clank, and the sound of running over every little dang crack and pebble in the road. Welcome to progress! Better get used to it, with the AZC bar, there's no going back to rubber M-Bar bushings.... -

I'm not convinced a Haynes manual is going to have much useful detail on cig lighter replacement. The factory service manual may be a bit more helpful.. xenons30.com under the Reference tab for a download.

-

The correct approach is to disconnect the lines at the engine bay side and plug the heater hoses, don't connect together. This short circuits the head cooling, last thing you need in hot weather. Yes its more work as you have to find suitable plugs. short 3/8 or 7/16" bolt will likely do. There is a wonderful 500 + post thread on here about head cooling and the do's and don'ts.

-

Make sure all three carb mechanical idle screws are not touching the arms, ie all 3 carbs are at closed throttle blades. Remove the firewall J-hook from the end of the rod. Remove one end of the three connector links so they are all free. Put a straight edge across the top of the 3 arms and make sure they are on the same plane, AND ensure the line formed by the straight edge is parallel to the round rod going through the rod ends. Use something rigid and preferably not a ruler that can flex. Something with a nice flat straight face so it can rest firmly on each arm. Make sure you touch each arm the same distance from the rod, like right near the end. Adjust the round rod to arm connectors to achieve perfect alignment. Look from side and top to compare your straight edge to round rod for parallelism. Make one connecting rod the right length to mate to its carb arm. Make the other two connectors the same length as the first one. Measure carefully. If the other two links don't now connect exactly to their carb arms without moving anything, then either the carb throttle shafts are not in the same position or the 3 arms to the round rod are not straight/parallel. If they are out by less than 1/4 turn of the threads, and you are positive the arms/rod are parallel, then adjust the connector lengths to fit. The three carbs have a small amount of mounting to the manifold "flex" due to the insulators and how tight you make the bolts on the rubber washers, so the error may be at the carbs, not the arms. Keep playing this game until everything is smooth. Good luck!

-

yup, I think I have the gas tank side. Its not perfect, few cracks, but its all there. Please send email to z240@shaw.ca and I'll send pictures.Jim

-

maybe, just maybe. I have one side I think, let me dig it out...

-

Could you flip the driver seat backrest all the way forward, move the seat all the way back to the rear and take a picture behind the seat, fairly low down, to show how the seat base fits up against the angled hump that rises from the floor to form the shelf behind the seat? And how the seat back connects to the seat base? With you in the seat, seat all the way back, with the back rest at a comfortable angle for you to drive, does the seat back touch the wheel well housing? IT should be very close. If there is a ton of room yet, the seat is not back far enough for me. My concern with most aftermarket seats is how the seat base/back fit into area behind the seat to allow the seat back to fit ABOVE the first angledhump off the floor, allowing it to almost touch the vertical luggage riser, while the seat base still remains low and in front of the hump, thus maximizing leg room while simultaneously maximizing head room. The stock seats have a unique design in that the back rest is quite far behind the back of the seat base, allowing it to nestle into the stock floor contours allowing for maximum setback. So many aftermarket seats have the back/base connection points close together or the seat base actually protrudes behind the seat base, preventing them for going back far enough to suite the taller driver. These look pretty good from what I can see. Very thin base, and that back/base connection point looks quite rear-offset. Just would like a few more pics to confirm. Thanks!

-

They are 8 x 1.25 mm thread and are two different lengths. Use the body of the pump to measure the length then add 2 or 3 times the diameter or ~20 mm more to get the total bolt length (from under head to end of threads). Grade 5 or JIC 8.8 is fine.

- 1 reply

-

- 1

-

-

Is there a silver spacer pipe about 2 inches long pressed onto the bottom of the insert or some other spacer? Is there anything else in the strut tube at the bottom that might be causing this up-lift? Dig in there with a light and a stick and dig it out. Take both inserts out and measure the depth into each strut tube from the top rim to the bottom. If both inserts are the same length then there has to be something in the bottom of the strut tube. Measuring should show you the difference. Once this is sorted out, remember you want about two threads of the gland nut protuding when its tight. You want the gland nut to press on and lock the insert into the strut tube. The gland nut must not bottom out on the top of the strut tube.

-

Hang on, I have a 77 door and a latch here, what am I thinking! I can take pictures tonight if I remember. Trying to get baby prepped for a 1400 km weekend excursion so I'm a little distracted. Send me a reminder to z240@shaw.ca