-

Posts

1051 -

Joined

-

Last visited

-

Days Won

9

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Chickenman

-

Which vac hose to tap for boost gauge? (with pics)

Chickenman replied to AlbatrossCafe's topic in Turbo / Supercharger

Red or yellow Vacuum cap should be fine. Do I get a prize?? -

I've occasionally seen Fiberglass replica rear valances on E-Bay.

-

To answer your first question. Yes, bring #1 to TDC. Then rotate the Trigger wheel backwards so that the Missing tooth passes the Vr sensor at least 60 to 70 Degrees ( 70 preferred ) before TDC. That will be your course setting. Then make the " Fine " setting by adjusting #1 Tooth angle. I take it your trigger wheel is held in place by a Center bolt and can be infinitely adjusted?

-

The sensor has to be mounted so that the missing tooth passes the sensor 60 to 70 Degrees MINIMUM before the piston reaches TDC. That is because a programmable ignition system does not actually ADVANCE the ignition timing. With an old style points system, the breaker plate physically moves the points ( or VR Reluctor ) vian Mechanical weights and Cams and the Vacuum pot. That physically does move the sensor location and ADVANCES the ignition. With a programmable system, the sensor location is fixed. So you have to start of with a figure that is higher than your maximum advance ( which can be up to 45 to 50 degrees BTDC in light load cruise mode ) and add a margin for the CPU to make calculations. So the ECU has to know when the piston is APPROACHING TDC ( of #1 cylinder ) Lets say you want a timing figure of 10 BTDC. Sensor is positioned so that missing Tooth pases sensor at 70 BTDC. 70 - 60 = 10 BTDC. Now lets say you want 40 degrees of advance at cruise. 70 - 30 = 40 BTDC. The ECU just delays or RETARDS the timing less. Always remember that the CPU needs some time to make these calculations. If you place the VR sensor too close to TDC, so that the missing Tooth only passes the sensor at say 45 degrees BTDC, the ECU may not have time to do all the calculations and subtract the necessary timing amount. Then timing fluctuates. Then you have to Sync the ECU Timing to the engine Timing with a Timing light. Usually to a Locked Timing of 10 BTDC. This is done in the Software. by adjusting #1 Tooth angle or by using the Trigger Wizard., depending on type of Ignition system used. All this is is a fine Tuning. You are adjusting the basic idle with software, instead of twisting the dizzy as with an old style Mechanical system. That's the only difference. Once you wrap your head around that it becomes easy peasy. What version of MS do you have. MS2 and MS3 are pretty simple. MS1 can be a bit tricky as it's ancient.

-

You may want to check the dizzy cap and rotor now. By having such a large gap on the testing tool, combined with the plug gap... you could have created an Arc Over and carbon traces inside the dizzy cap or rotor. Get a magnifying glass and look for Carbon Traces jumping form terminal to terminal or even to the base of the dizzy cap. They will look like hairline cracks or a line dean with a sharp pencil. Check the rotor as well. And also between the Coil center tower and the two primary terminals. Arc over and carbon traces can form there as well. Bottom line. You probably didn't have an INTERMITTANT spark. You had a spark that found a path of less resistance... and it went there instead of through the spark tester.

- 31 replies

-

- fml

- more z car torture

-

(and 1 more)

Tagged with:

-

In the video... I think you simply have your spark gapping tool adjusted too far out I use these things all the time, and that is a huge gap. What spark leads are you running? If carbon core you could have a lead that has deteriorated and has higher resistance. Carbon core wires are 1960's and 1970's technology. They have no place on a High Performance car these days. Never use solid core copper wire. Will cause a lot of electrical interference. NGK makes an excellent spiral core HT set for our cars for a very reasonable price ( Typically $19.95 online ) . Part number is NE61 ( SKU) or NGK8105 ( Item number ) . Available at any decent Auto Supply shop. MSD and Magnacore also make a very good spiral core wire. But a bt more expensive. Isee you have the gapping tool hooked in series with your spark plug, condition of plug also comes into play. And added to that you have the resistance of the plug gap ADDED to the resistance of the overly large testing gap. This is improper use of the Tool. Normally I test spark output with a gapping tool by connecting the ground lead directly to a good engine ground, not to the spark plug That gives you a better indication of the True spark condition. You could also have a carbon trace inside the dizzy cap. Or the spark could actually be jumping to an adjacent plug terminal. Electricity always takes the path of least resistance. Air is a very good insulator. A Carbon trace less so. Coils don't go intermittent per cylinder. You have a good sharp spark. It is Blue and you can hear it snap. That's all good signs of a healthy coil and module. Cut that spark tester gap down by at least half and connect it to an engine ground.

- 31 replies

-

- fml

- more z car torture

-

(and 1 more)

Tagged with:

-

Rock Auto has A1 Cardone remanufactured Turbo dizzies for $182 out right. You will need a Cap and Rotor . I would recommend the Beck/Arnley brand. usually OEM Japanese parts for Nissan. https://www.rockauto.com/en/catalog/nissan,1983,280zx,2.8l+l6+turbocharged,1209406,ignition,distributor,7108 I would recommend checking all the clearances on the Dizzy. They often install a later Maxima pr Pathfinder CAS, and it has a couple of plastic " Nibs " on the bottom that do not allow the CAS to sit square. Mine was rubbing on the Trigger disc. A few minutes of " Blue Printing " and all was good. Also, sometimes both the dizzy body and the CAS are threded for mounting screws. It's a difference in how the later CAS units are mounted. If you find this is the case. Remove the mounting screws and CAS . Drill out the three threaded holes in the dizzy body so that the mounting screws can be installed from the bottom and thread into the CAS. It's self explanatory when you see it. And you will want to get the custom 54mm L28ET 12 + 1 Trigger wheel from DiyAutoTuning.

-

Race car: P79 + flat tops for turbo engine? (Moderate boost)

Chickenman replied to turbogrill's topic in Nissan L6 Forum

A correctly sized ( and low pressure loss ) intercooler will dramatically reduce charge temps which will also reduce the knock threshold.. It will also reduce the boost necessary to produce the same horsepower. Cooler air is denser. Same HP with Less boost = better efficiency = lower cylinder pressures = less chance of detonation. A Win/Win situation. The ability of a Modern ECU ( or standalone ) to precisely control the AFR and Timing at any RPM and Load allows you to maximize the Torque and HP potential of the engine. It's very hard to improve modern EFI efficiency because of the feedback controls. Modern Dual WB Knock sensors really allow the manufacturers to push the efficiency and power envelopes. Also, car manufacturers have to make things conservative in case low Octane fuel is used by mistake. Race cars don't have that issue. The ZXT did have a factory Knock sensor... but it was a dinosaur compared to what is available today. You can also make Timing digressive at Peak Torque with programmable ECU's. Ramp timing up aggressively at low RPM's to generate maximum Torque, then back off a couple of degrees at Peak Torque ( Peak Torque is usually where detonation will occur ) then ramp it up again ( if necessary ) after Peak Torque. Cylinder heads that are prone to detonation ( N42/N47 for example ) respond well to this Timing strategy. You can also use some extra fuel to control detonation. Kind of a " Band'Aid " fix... but it will work. This should all be done on a Load Cell dyno of course. You can also do individual fuel and timing trims with most stand alone ECU's. #5 and #6 are known to run a bit hot on the L-6. So you can pull a small amount of timing from those cylinders. Or add a bit of fuel. Run multiple O2 sensors ( or EGT probes ) and you can dial in the ideal AFR for each cylinder.. Most Intake manifolds, especially stock manifold, never have equal air distribution from cylinder to cylinder. -

Yep... with an IAC the TB should just be cracked open. Just enough to prevent the butterfly from being fully closed and digging into the throttle body bore. With a large Camshaft, you may have to crack the butterfly a bit more, as the IAC can run out of available opening range.

-

Race car: P79 + flat tops for turbo engine? (Moderate boost)

Chickenman replied to turbogrill's topic in Nissan L6 Forum

As long as you can get decent fuel ( 93 to 94 Octane ) , 8.6 CR is not too high IMHO. Done all the time. Race fuel would be a piece of cake Nissan went really conservative on the L28ET CR, because of no intercooler and archaic ECU controls. You can push the envelope much further with some upgrades and a decent Standalone ECU. manufacturers in the 80's through 90's were very, very conservative on most Turbo motors. Now you have EcoBost 2.3L 4 bangers pumping out 350HP... stock!! ( Focus RS ) Add a couple of VW Bosch WB Knock sensors to the block would be a smart idea on a race engine. Not too hard to do. I'm sure Tony D knows how. -

Here's some reading to make your Brain hurt. Written for MS2, but should apply to MS3 as well: http://www.megamanual.com/ms2/IAC.htm

-

Good explanation of various types of IAC valves. http://ricksfreeautorepairadvice.com/how-does-an-idle-air-control-valve-work/ https://www.youtube.com/watch?v=oRo5nn9ux1M

-

With an IAC enabled you have to physically adjust the TB butterfly more closed than if you run without an IAC. The Jeep IAC is a Stepper motor design and will always be open a certain amount. If it does not receive an ECU command it will default to the last commanded stepper position.

-

Megasquirt Relay Board with Bosch 044 fuse blowing

Chickenman replied to dpuma8's topic in MegaSquirt

That is a possibility. Relay could be overheating on Relay Board. May have Thermal protection and relay is opening. Or some other intermittent electrical disruption. Or Bosch pump is cavitating badly and it takes a while to cool it down. Pump cavitation can do nasty things to a pump in short order. Fortunately the Bosch 044 is a roller vane design, which are much more robust than a Ceramic Turbine design. -

Megasquirt Relay Board with Bosch 044 fuse blowing

Chickenman replied to dpuma8's topic in MegaSquirt

Quote from Aeromotive on this exact problem. Could definately be Pump cavitation. I would definitely be looking at replacing that G3 and checking hose sizes. Further info on Pre-Filter restrictions. Read this: http://aeromotiveinc.com/wp-content/uploads/2014/12/TB_101_InletFilter02.pdf -

Megasquirt Relay Board with Bosch 044 fuse blowing

Chickenman replied to dpuma8's topic in MegaSquirt

Sorry... but I disagree with that. The feed pump absolutely MUST keep up with the main pump under all conditions and keep the main pump submerged in the Surge tank. You run the Ffel level in the surge pump too low and the Bosch pump will cavitate and you can kiss it good bye in a hurry. But likely you will have melted a piston by then. Feed pump does not have to be high pressure. But it must be high volume. Think of a Surge tank as a float bowl. Yes, there is some reserve, but with a GT3076 and 550cc injectors you can suck a Surge tank down pretty fast. Also depends on mounting locations of pumps etc. Pictures will definitely help. G3 Fram filter is definitely a restriction on a motor of this potential. I've run into problems with a G3 pre-filter. on a hot day on my NA motor. Switching to a Aeromotive 100 Micron filter. BTW, have a look at the 280Z stock fuel line hose sizing to and from the Fuel pump. Inlet is 11mm ID ( 7/16" ) . Outlet from pump is 9mm ( 3/8" ) That should tell you something. The feed from the fuel tank to the scavenge ( or main pump ) pump and the feed from the scavenge pump should always be larger than the outlet size from the Main Pump. If Main pump is AN-6... inlet hose should be AN-8. -

L28 N42/N42 NEED HELP CHOOSING TURBO!

Chickenman replied to RefreshRate's topic in Turbo / Supercharger

The P90 head with Flat Top pistons would have been ideal. The P90 with dished pistons is the stock The P90 head with dished pistons still has an advantage over the N42 head. The combustion shape of the P90 has a better quench area. Quench area creates turbulence in the mixture and helps prevent detonation. That is critical on a Turbo motor. When you add a thicker head gasket, you reduce quench... so you can actually end up with an engine being more detonation by reducing the compression ratio that way. Especially if you have an engine with a head design that is prone to detonation... like the N42 and N47 are. Not saying that you can't make an N42/N47 combo work... but it will be less than optimal. And for crappy California 91 Octane fuel, I would definitely run H20/Meth injection as a fail safe with an N42 head. That's just my personal opinion mind you. Either way with a good intercooler and proper engine management you can run a higher compression ratio than what Nissan did back in the day. Programmable ignition timing and programmable fuel curves will go a long way on controlling detonation. BTW, I have a NA F54 Flat top with N47 heads and 10.3 to 1 CR. I have to be careful with ignition timing on that with 91 Octane. Stock(ish ) distributor at this point.- 13 replies

-

- turbo

- n/a to turbo

-

(and 1 more)

Tagged with:

-

L28 N42/N42 NEED HELP CHOOSING TURBO!

Chickenman replied to RefreshRate's topic in Turbo / Supercharger

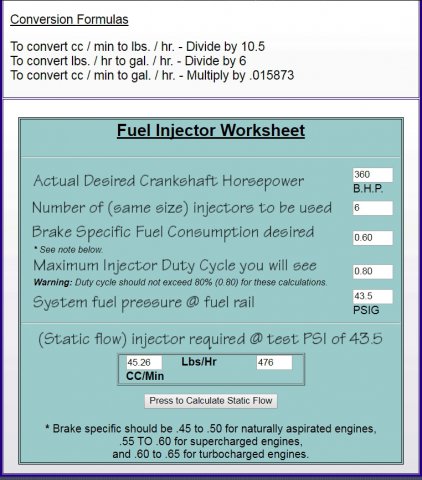

On injectors, I would recommend going with 550's. This will give you room for expansion. At some point you will be bitten by the Boost bug and are going to run out of injector with the 440's. The 550's are not crazy big and will idle nicely with a standalone ECU controlling things. Using the following calculator, you will see that 360 Crank HP ( 300 WHP using 20% loss ) with a BSFC of .60 ( Typical Turbo value ) and 80% duty cycle ( what you should be aiming for ) requires 476 cc/min Injectors. So your 440's may already be too small for your goals. Better to be a bit too big with injectors than too small. https://www.rceng.com/technical.aspx- 13 replies

-

- turbo

- n/a to turbo

-

(and 1 more)

Tagged with:

-

L28 N42/N42 NEED HELP CHOOSING TURBO!

Chickenman replied to RefreshRate's topic in Turbo / Supercharger

Sorry, had your build mixed up with Zeiss 150. You would be better off with a P90 head and the N42 block IMHO. Does your N42 block have dished pistons or Flat Tops? That makes a big difference to the CR. CR between 8.0 to 8.5 will be fine with a P90 head. The N42 head is too prone to detonation, unless your weld up the combustion chamber. And that's a big job. The the N42 is more of a NA head. The P90 is much better for a Turbo motor. Better quench than N42/N47 as well. BTW, adding a thicker head gasket actually makes quench worse, and can increase detonation. So you might want to re-think that. My recommendation is to build two short blocks. One with a Mule engine. Stock short block with dished pistons. Build it decent., but don't put a ton of money into it, Basically just freshen up a good used short block. This is your sacrificial Lamb for when things go Chernobyl. And they will... at some point. Melt down the cheap motor while you are learning how to Tune a Turbo. Once you have the Tune and Boost levels sorted... then put in the Big $$$ short block. Local Road Racer made 400 hp on a stock short block with Cast pistons. T3/T4 at 15 lbs boost. Engine lasted 3 seasons of Road Racing till he broke a Stock Piston ( Ring lands ) . He was expecting half a season. He actually started cranking up the boost higher and higher , because he wanted to put the new $$$ short block in... but the old Mule engine wouldn't die!!- 13 replies

-

- turbo

- n/a to turbo

-

(and 1 more)

Tagged with:

-

L28 N42/N42 NEED HELP CHOOSING TURBO!

Chickenman replied to RefreshRate's topic in Turbo / Supercharger

A basic T3-T40 50 Trim with .63 AR will work just dandy. Note on head gasket. No need to drop compression that low. Too low of compression will turn the car into a Dog. I think we discussed this in another thread. Or was that someone else?? Edit: It was someone else. Zeiss150. But you may want to check out his thread. http://forums.hybridz.org/topic/128138-low-compression/ Is your engine the N42 with Flat Tops and P90 head? If so use the stock thickness head gasket. OEM Nissan gasket is good. ARP head studs. A good intercooler ( Look at Treadstone ) 93 pump gas. You actually want CR in the 8.5 range. Nissan was far too conservative on that motor. Lack of intercooler was one reason. If you can't get 93 or 94 Octane fuel, look into adding Water/Meth injection. Lots of local 510 Turbo guys running 10 to 15 lbs boost on L -series engines with CR from 9.0 all the way up to 10.5 CR with 16 lbs Boost. Last example is a HEAVILY modified engine that Dyno's 300 RWHP out of a 2.1 liter L20B on VP C16. ( We don't have much access to E85 in BC ). On the street with 93 Octane he runs 10-12 PSI Boost. Big intercooler, lots of H2O/Meth injection and a very, very well built engine ( By Specialty engineering ) . Oh yeah. And the fellow ( Keith law ) is old school. So he runs it with a custom built WEber downdraft in a custom blow through application. He's been running this combo for over 30 years now...- 13 replies

-

- turbo

- n/a to turbo

-

(and 1 more)

Tagged with:

-

Megasquirt Relay Board with Bosch 044 fuse blowing

Chickenman replied to dpuma8's topic in MegaSquirt

The surge tank wiring and plumbing also need looking at . The Carter scavenge pump should be on it's own separate Bosch relay ( Not on the MS relay board ) and needs twelve gauge wire as well. Where is the surge tank located. Again it should be located close to the fuel tank and as low as possible. All electrical pumps work best as pusher pumps. They do not work as well as puller pumps. The Surge tank should have a vent line leading back to the fuel tank. With out a vent line, you could create an air lock in the surge tank. One other thing. Does the Carter fuel pump have enough volume to keep up with the Bosch 044 pump? It must be able to supply MORE volume than the 044 can push out at maximum capacity... otherwise it just becomes a restriction and the surge tank will run low, causing cavitation in the Bosch 044 FP. -

Megasquirt Relay Board with Bosch 044 fuse blowing

Chickenman replied to dpuma8's topic in MegaSquirt

I would install the check valve first of all and see what that does. Without the check valve in the pump the Fuel Pressure will definitely drop. The FPR alone won't stop the pressure drop off. However, if I understand you correctly. After a 30 minute stop ( and Heat soak ) the fuel pressure only comes up to 10 psi. How long does that last? A heat soak issue ( fuel percolation ) should clear itself pretty fast. Within a minute or so maximum. It may be possible that the Fuel Pump is losing it's prime with out the check valve installed. Where is the fuel pump located? It should be at the rear of the car, close to the fuel tank and mounted as low as possible. Make sure the Fram G3 sure is not plugged or restricted. A 100 Micron filter ( Aeromotive makes a good pre-filter ) with a fairly large surface area will work well. Do not put in a Post pump filter ahead of the pump. These are typically 40 Micron or smaller and restrict fuel too much when used before the pump. Edit: Actually, thinking about it, the Fram G3 is a post pump filter. It is designed to be used under pressure.. not suction. With the added volume of the Bosch 044, sometimes the paper elements collapse. It also does not flow enough for you application. I'd have a close look at that G3 filter. Other possibilities. FPR may have a bit of debris stuck in the seat or the valve is sticking open. Take it apart and inspect. Aeromotive FPR are usually very high quality, but even the best quality parts are sometimes defective. Check for any kinks or restrictions in fuel lines. Another possibility, and this can be a SOB to find, is that the fuel tube in the Fuel tank feed is rusted and has perforations in it. This can suck air and cause the FP to olose prime. Usually happens below a certain fuel level in the tank. But the first thing I'd do is put that check ball back in place. Simple and it may do the trick... . -

L28 Build Thread 75 280z (N/A to Turbo Conversion)*UPDATED

Chickenman replied to RefreshRate's topic in Nissan L6 Forum

Just some info. The stock rods and crank are forged from factory on all L-series engines. And A-series as well. They are VERY strong and have excellent metallurgy. . Some basic rod prep ( polishing, shot peen and big end sizing check ), balancing and some ARP bolts and you have a pretty darned good set of rods for not a lot of money. -

The pile of parts in my bedroom is adding up. ( I live in an Apartment ) Some of them have been there for 3 years. Coil-overs, 4 wheel disc conversions, JDM bumpers, Pioneer Amp and a few other things. Mind you, I have an excuse. I've been having too much fun actually driving my 280Z !!

-

PM sent regarding ECU choice. GL with your project !!