NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

Did you get propeller shaft u-joints, or half-shaft u-joints? They're different. Post the MOOG part number,

-

It's a vent. In a low pressure area to pull air from the cabin. The badge pops off and you'll see the hole.

-

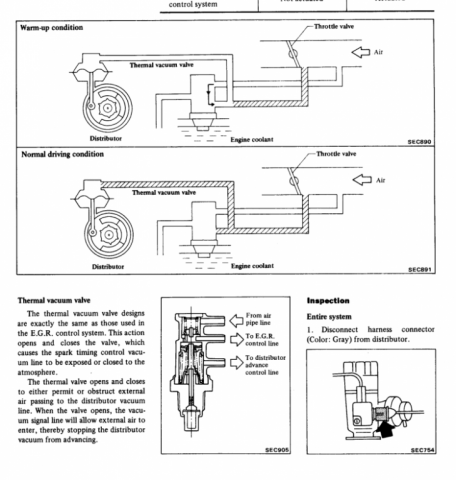

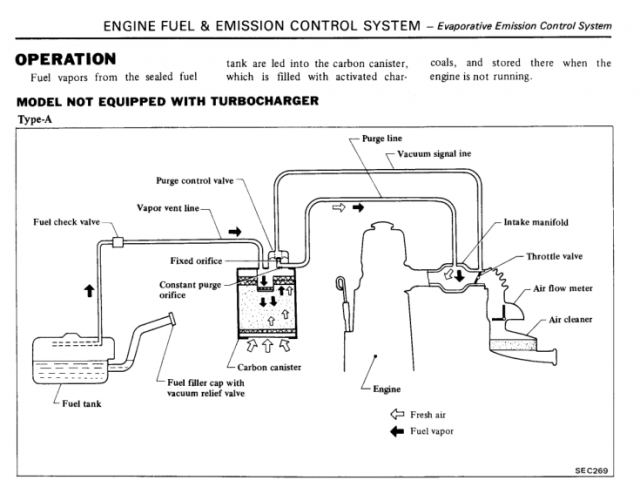

I just browsed through that section and have to admit it's not very clear. I'd guess that "air pipe" means throttle body port, based on the diagram and port locations. So, even based on your picture, the EGR and vacuum advance lines shouldn't change at all with throttle body. They're connected to the TVV. The canister has it's own ported vacuum line. Called "vacuum signal line' in the second drawing. So it looks like you could have a T off of the MSA port, with one hose going to the top port of the TVV, and the other going to the cap on the canister. Usually the cap is labeled, and the vaccum line is a small one. You should check your old throttle body though to see why there are three ports. It may be that they all actuate at different times which would mean you won't be able to match it exactly with the MSA TB. You can usually see the ports inside the TB, by the blade, Nissan really regressed in 1982, in FSM quality.

-

Get in to the FSM and figure out which hoses need ported vacuum, which need full time vacuum, and which need switched vacuum. Then figure out where to get those vacuum sources, using tees off of the MSA TB, or making new holes. Not sure what you mean by "vapor valve", maybe the charcoal canister purge line?, but there are no vacuum hoses that should ever pull raw fuel. Could be that you've confused your hoses and you're actually looking at the FPR vacuum hose, and your FPR is damaged and leaking fuel. At the least, figure out the right names for what you're looking at.

-

Air intake temperature SOAR when I step off the gas.

NewZed replied to supernova_6969's topic in S130 Series - 280ZX

Your comment about the sensor location was buried, and in parens. Missed it. Follow the wires. You should really do the conversion work, if you want more responses. Most of the forum members work in Farenheit. (1.8 x Celsius) + 32 = Farenheit, for anyone who wants to do the math.- 28 replies

-

- air intake turbo temperature

- air intake temperature

- (and 3 more)

-

Air intake temperature SOAR when I step off the gas.

NewZed replied to supernova_6969's topic in S130 Series - 280ZX

Where's the sensor and how is it mounted? You might be measuring heat transferred from metal at low air flow.- 28 replies

-

- air intake turbo temperature

- air intake temperature

- (and 3 more)

-

Congratulations. You're ahead by -10 days.

-

You won't see a tiny voltage drop from low current flow unless you have a good meter. Try measuring where the power should be going when you turn the key. The starter solenoid, when you turn the key to Start.

-

Turned to where? And where are you measuring?

-

You can use the small diagrams in various chapters from the Post #6 link, or this giant one - http://www.atlanticz.ca/zclub/techtips/wiringdiagrams/78_280Z_wiring.pdf At least you have a meter. You could have used it to determine that you had power to the coil, for example, beofre using the starting fluid. You have the basic tools, and some knowledge. You just need to use it in an orderly fashion. Instead of checking the relays, check what they power, for example. If it doesn't have power, check the relay power source (the ignition switch for example, or the power wire to the EFI system at the battery terminal with its green fusible link), then check the relay. You'll be surprised how easy it was when you find the one thing that wasn't getting power that should have been.

-

There's a black 280ZX, looks about 1979, in Repo Man.

-

PLEASE HELP, rear brake conversion issue

NewZed replied to Blob1620's topic in Brakes, Wheels, Suspension and Chassis

Close maybe, at least on names. Maxima calipers, 300ZX rotors, on the Z cars. Scroll down here - http://www.californiadatsun.com/brakes/brake-conversion-upgrade-kits/ The KE is there, and the shapes look similar. This guy used to be Datsun Parts LLC. Changed the name. Same parts, same guy, though.- 17 replies

-

- s30 to s130

- disc brake conversion

-

(and 1 more)

Tagged with:

-

That's a good point. Considering the extra mounting holes in the front of the long nose that aren't used though, and the modifications to the bar end bushings after a year or two in the 240Z, and the big chunk of iron they strapped on to the bottom of the cross-member later, I'm still seeing a cobbled together system that they never really got right. If a person has never been under a Z, like I hadn't when I got mine, when you first get a look at all of those parts, there's a lot of time spent thinking "what the heck were they trying to do here". I'd bet the first prototype cars had a more solid mount but the diff howling and clunking inside the unibody tin can was just too much to stand. Then they started cobbling.

-

260z, suby lsd, wolf creek adaptors, driveline bind/popping noise, HELP!

NewZed replied to evoog's topic in Drivetrain

I'd go with you picked the wrong shop to work on your diff and they screwed it up.- 14 replies

-

Looks like automatic uses a different bolt. http://www.carpartsmanual.com/datsuns30/DatsunZIndex/PowerTrain/TransmissionCase/Automatic/FromApr-71/tabid/1705/Default.aspx He probably has the swap done already...

-

Are you swapping 5 speed for 4 speed, or 5 speed for automatic? The manual transmissions are almost identical. Don't know about automatics. The local Nissan dealer might be able to get them. http://www.carpartsmanual.com/datsuns30/DatsunFairladyZIndex/PowerTrain/TransmissionCase/5Speed/tabid/1702/Default.aspx http://www.courtesyparts.com/bolt-p-234686.html http://www.courtesyparts.com/bolt-p-234688.html

-

Time for basics. Power to coil, etc. You just installed a completely new electronic fuel injection system, MSD ignition system, and electronic distributor (assuming the Mallory is not points). Some meter work should be a piece of cake. Seems like you're in denial that one of your new parts might have broken. Could just be that a wire fell off.

-

You didn't mention the basic "confirmed spark" or "starts with starting fluid". At least you'll know if it's spark or fuel. The Unilite modules aren't the most durable, I think. Here's a test procedure, if you find that you don't have strong spark - http://static.summitracing.com/global/images/instructions/MAA-unilitedistributorwiringdiagramtestproced.pdf

-

Can you really see that rigid cross member as like the loose, floppy leaf spring of the Z? Seems a stretch. I missed johnc's comment, and repeated something similar in my post. Funny though, a lot of time is spent on making the unibody more rigid, with bracing and roll cages, but the mustache bar mounting points seem like obvious areas to mount a rigid cross-member to, for stiffening the body. In the bigger picture maybe the Arizona bar should be mounted rigidly (get rid of the urethane donuts on the ends), and the elastic dampers (urethane or rubber) should be placed at the diff, like in the ZX post mount. Stiffen the tail of the box, but keep a little bit of damping at the diff.

-

Didn't Nissan go essentially solid with the ZX system? Only rubber bushings damping slight movement, with rigid metal attachment points. The mustache bar system seems unbalanced from a design view - the front rubber-metal sandwich allows much less movement than the mustache bar. It gets overworked. Probably why they wrapped a belt over the top of the diff nose, to help out. Could also be that the mustache bar wasn't put there for the diff, or for ride quality, but to take loads off of the body mounting points. Maybe it started out solid and they went to the bushed spring as a fix for other problems. Overall, the Z diff mount system is an odd collection of parts.

-

Did he say why? Appearance, measurement, package...?

-

If you have short axles because the Honda diff is wider than the R200, you might be able to have an adapter made. Like the TR6 guys use. Note that one adapter is thicker than the other. One of those things you have to pay attention to. http://tr6.danielsonfamily.org/DiffGoodparts.htm

-

The reason they do all of this is because there are no simple axle swaps to get what you want. The viscous diffs use a different axle design internally than the early open and clutch LSD diffs. No swap and go options. Besides that, is the weak Honda diff the same width as the R200 you're installing? If not, the axles you want to use are probably too long. There are many things to consider and many threads describing how people have missed one or two of them.

-

The issue gets pulled out and beat up occasionally. There's a ton out there on how to get newer diffs working in older cars and it always leads to custom CV axles as the simplest path to success. People have cut and welded four bolt flanges on to 6 bolt stub axles so they could use the later model viscous diff. You could do the same. By the time you add up the design time, and pay the shop to do the precision work (proper welding, runout on the flange surface, issues with control arm interference [that 6 bolt flange is big and runs close to the arm on the Z cars], etc.), a custom CV axle looks like a better option. Just easier to cut and spline a shaft so that it can use the ends you want. Find a driveshaft shop that does CV's, give them a length to shoot for, and the two ends and they can probably get it done.

-

Look through what the kit has and determine what each bushing does. Then decide if you need the whole kit or just a few. Think about what affects the handling issues you're trying to change and focus on affecting those parts. You mentioned old shocks, but decided to buy a bushing kit. Several of the bushings sacrifice ride softness for handling precision. One man's increased responsiveness and road-feel is another man's harshness. If you're planning other changes like low profile tires, you might do those first, since they'll make the ride harsher too. Keep your variables separate so you know what's doing what. For the crowd - Is the polyurethane T/C rod bushing an issue with the ZX? I know it is with the Z's, maybe not with the ZX. Nissan moved the rod from mainly compression to tension, from Z to ZX. May have changed some other design aspects.