NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

John Coffey explored the myth of the shorter half-shaft. He died a few years ago though and it looks like the Facebook post is no longer active. I did find an old Hybridz post about it though, with the text copied over. Basically, they are all the same. The question about R200 width in the 240Z is discussed too though, but it's never r really been cleared up. But there were subtle changes in the half-shafts over the years. There's a bunch of part numbers. http://www.carpartsmanual.com/datsun/Z-1969-1978/axle/rear-axle-drive-shaft

-

Taking orders is not the problem. Completing them is. https://youtu.be/4T2GmGSNvaM?t=36

-

Apparently they have moved to a different location. Wonder if they'll make it. https://www.facebook.com/apexengineered/ https://www.facebook.com/apexengineered/photos/pb.159803257857337.-2207520000../1171773006660352/?type=3&theater

-

I blew up my kid's 240.....sorta

NewZed replied to jvandyke's topic in Gen I & II Chevy V8 Tech Board

You can. Somebody removed some of the cover bolts for some reason. Might be a good idea to drain the fluid if it's a wrecking yard, they have to do that. You might want to pull the cover and take a good look inside before buying. Look for chipped gears, burned bearings, etc. You can pop the side axles with a big screwdriver or tire iron. Sometimes you need a wedge, like a cold chisel to get them started they can be really tight. Check the bearing seat and seal surfaces on the axles for scorching and wear. People run them low on fluid sometimes. Your R180 bolts are the same I think so you can use those on the cover if you get it. -

The breaker plate is the part that rotates when vacuum advance is applied. It moves the pickup coil in relation to the distributor shaft to advance the timing. The distributor shaft itself can rotate freely but the breaker plate can be locked to it instead of free. Easiest way to check is to remove the vacuum advance canister and gently try to rotate the plate. If the balls are rusted in place you might break the plastic cage so be careful. Think about advance curves also. There the vacuum advance and the centrifugal advance. Once you get in to them there's all kinds of small details to worry about.

-

Forgot to say, have you checked the breaker plate on the distributor? Often they get locked up or broken and don't rotate anymore. You could use a 280Z distributor in its place. Or a 280ZX unit. The ignition module on your 260Z is one of the very first models and those old ignition modules fail on a regular basis. In short, consider the sum of the parts involved. And, the early electronic ignitions were not "high energy". They were just points replacements. Same plug gap,. 1978 was the first high-energy ignition module.

-

Looks like they are definitely different parts from the 280Z parts. Probably just the way it mounts on the breaker plate. If you could get a 280Z coil to mount next to the reluctor wheel correctly you'd probably be fine. Might be worth an experiment if you can get an old 280Z pickup to try. Here's the 260Z part numbers. Different from 280Z. Part #7. http://www.carpartsmanual.com/datsun/Z-1969-1978/electrical/distributor/260z Here's 280Z. #9. http://www.carpartsmanual.com/datsun/Z-1969-1978/electrical/distributor/280z

-

I blew up my kid's 240.....sorta

NewZed replied to jvandyke's topic in Gen I & II Chevy V8 Tech Board

Your halfshafts will bolt up. I was thinking of the stub axles, which are different for the R180's. But, if you can get the halfshafts for a decent price they're good to have as spares. People with V8's break those too. -

I blew up my kid's 240.....sorta

NewZed replied to jvandyke's topic in Gen I & II Chevy V8 Tech Board

Never mind. Blew it up myself, looks like an r200. Somebody already converted to R200. I think, based on the lack of side bolts. Ask for the half shafts too. -

I blew up my kid's 240.....sorta

NewZed replied to jvandyke's topic in Gen I & II Chevy V8 Tech Board

-

I blew up my kid's 240.....sorta

NewZed replied to jvandyke's topic in Gen I & II Chevy V8 Tech Board

AydinZ71 is right, I didn't look at your picture. You already have it. Your drive (propeller) shaft will work. The distance for an R180 and an R200 is the same. They are the same length. One area where you can get screwed up is if the R200 is from a 1975 280Z. For whatever reason Nissan used a different bolt pattern for the pinion flange in 1975 only. If you can find out it might save you some trouble. -

I blew up my kid's 240.....sorta

NewZed replied to jvandyke's topic in Gen I & II Chevy V8 Tech Board

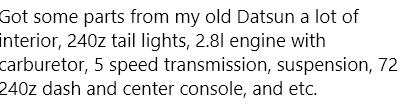

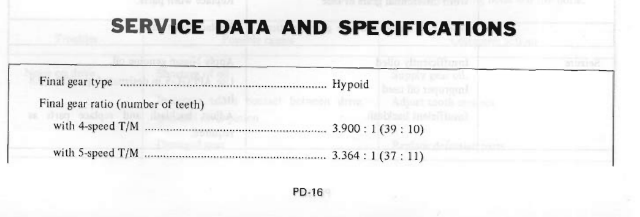

The Facebook R200 seems like a decent deal. Axles, half-shafts included for $200. Probably close to what you'd pay in wrecking yard prices today. I mentioned gear ratios in your other thread but with a V8 you could probably use a taller gear anyway. The torque doesn't need the low 3.9 and you'll get better cruising RPM with a 3.54. You only need an R200 diff mount and the curved cross-piece for the suspension drop-downs(to clear the bigger diff cover) to complete the package, I think, but should probably get something like the Technoversion RT mount to handle the power, if you don't have one already. https://www.technoversions.com/DiffMount.html Here's your other thread. -

You might need the halfshafts too, depending on which R180 you have, can't remember the details. Easiest would be to find a 76-78 junked 280Z and scavenge the parts. Sometimes you can get the whole car for less than the collection of parts. If you have to piecemeal it, the 280ZX's up 1983 (including) use an R200. Some use an R180 so you have to check to be sure. Check the ratios also. You might have a 3.9 now, but many R200's are 3.54.

-

Did you get new parts or used? The E12 modules are old and failing. You can use the red and green wires in the ZX distributor to run a GM HEI module.

-

Scroll down to the April 10 post here. Should have done some reading before you ordered. He is incommunicado. Good luck. Cancel that credit card charge if you can. S

-

Sounds like the stator or magnet or pickup coil in the distributor itself is broken or the wires have shorted. Download a 280ZX FSM and look in the Electrical chapter to see how to test those parts, or disassemble the distributor. In short, you probably have a bad distributor. Is it used? The bushings wear out in the ZX distributors, allowing the reluctor wheel to hit the pickup coil points. Here's a good description. https://www.atlanticz.ca/zclub/techtips/distributorrebuild/index.html

-

Just curious. What about the other guys? ZCarDepot and SilverMine? And Chequered Flag (Joe@ModernMotorsports's business)?

-

Maybe he needs another reach out. It's been almost 6 weeks.

-

Edited - the credit card charge challenging process requires oversight. I don't think that it's a given that the consumer always gets their money back. It's a process. If it was a U.S. business you could sue them in small claims court, report them to the attorney general in the state they are registered in, and also report them to the Better Business Bureau. Those are all remedies/actions for the consumer to take against companies that do not fulfill their obligations. Which is what Whitehead is doing here. But they're in Canada and the US Attorney General's office has a lot of other things going on right now. If a business needs a loan they should go to a financial institution. Whitehead has taken this person's money and is using at as collateral for loans or to stay afloat, paying their own bills. Often, what is happening here is a precursor to bankruptcy. Business will take consumers' money, use it to pay salaries, etc., delay as long as possible, then claim bankruptcy, leaving the consumer screwed. As JMortensen said though, there is a time limit. That should have been a sign, that Whitehead was stringing you along for a reason. They know about the time limit too. All in all, it's not a good sign. Looks like Whitehead is in trouble. Avoid them, until they either get back in shape or go under. https://whiteheadperformance.com/about-us/ Philosophy We are a customer service driven company We’ve built up and maintained our reputation over the last 30+ years by providing honest and friendly service, by going that extra mile to make sure our customers are happy and 100% satisfied with the work performed on their vehicles. It is no different today. Customer service is our number one priority.

-

Why didn't you just use the stock valve covers? Didn't you still have to redo things with the taller Holley cover? Just curious. What is the benefit of the Holley cover over the stock cover in the first place?

-

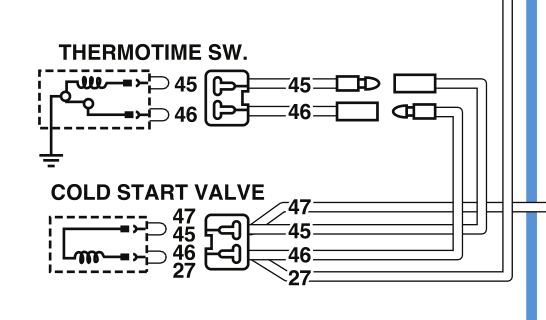

The wiring diagram might help. Looks like both wires get power so turning the key on won't tell you anything. One wire is the ground for the CSV and the other wire is the power to the internal heater in the thermotime switch. If you still have the bullet connectors in the harness you could use those to figure it out. One pin of the switch will have resistance from the internal heater (the curly line in the drawing). The other one will be very low resistance since it supplies the ground for the CSV through the switching portion. Measure resistance through the pins to ground, then connect the male bullet wire to the one with low/no resistance. Or, disconnect the CSV, turn the key on, and the wire that has power will be #47, from the relay. Which is connected to #45 at the terminal and would go to the side of the switch with resistance.

-

Just go ahead and start a thread with a big For Sale in the title. If it catches someone's eye they'll follow-up, if not your diff will get sold. You paid, so you have a legitimate usage of the site to sell parts, per the agreement as a member. Not really sure what's happening with the site. I think that SuperDan has lost interest. Or maybe something has happened to him. Classiczcars.com has a Parts for Sale page, and they like LSD diffs too. Good luck.

-

I think that what you're proposing is not the way that most people would get to a larger booster. Which is really all that you're trying to do. Swapping to a completely different pedal box to get a bigger booster seems like a more difficult path than necessary.

-

This part sounds like a failing ignition module. They overheat and stop working then start working after they cool off. Often they will stop working after getting the engine up to higher RPM. That's one way to test it, run it up to high RPM, watch the tachometer needle for weird behavior and see if it keeps running. This part is normal. Those lights are supposed to be on when the engine is not running, but the key is on. They should both turn off when the engine starts.