NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

Valve lash increases (looser valves) as the engine heats up, hence the bigger FSM spec. numbers for a hot lash adjustment. Just saying for clarity. The "starts better when cold" might be the better clue. What settings change as the engine gets warm?

-

Not cheaper though.

-

1/71 240Z Rear Wheel Cylinders

NewZed replied to rayaapp2's topic in Brakes, Wheels, Suspension and Chassis

The classiczcars guys might know more since they love the early 240Zs. http://www.classiczcars.com/forums/content.php Also, if you have the pieces, a complete strut and hub transplant, to the later parts might be an option. Nuts, bolts and a brake line. -

The block model number is cast in to the side of the block, just behind and below the driver's side motor mount. Yours should be an F54 block, but could be an N42. Even if it's an F54 though, you could have flat top pistons, not factory issue for the turbo motors. The head number is between the 1 and 2 spark plug holes, on the bottom edge of the head. With the CHTS shown in one of your pictures, yours will probably be a P79, P90 or P90A. Those two numbers will tell you something. Apparently the turbo distributor has a different drive "gear" that's why you have to change the "quill" (? - I think that's the right word) from the oil pump. Your pictures do show some hackiness so you could have a mix of parts. A fun puzzle.

-

It's just a ratio. If you don't have uneven drag on your wheels, you can mark both wheels and the pinion flange, then turn the drive shaft until both wheels turn one complete revolution. Count the number of turns of the flange to get the ratio. You'll have to guesstimate the .336, .54, .7 or .9 at the end. 1/3, 1/2, 3/4, almost all the way. If the wheels turn unevenly, you can lock one wheel, turn the flange until the other wheel does one revolution and divide the flange turns by 2. Use a torch on the metal around the plugs. Apply heat. It makes a big difference. No link in your last post.

-

Looks like a repackaged MSD 6AL. http://www.store.procompelectronics.com/index.php?target=products&product_id=36823 See MSD's instructions for the 6AL (6425 PDF, Page 2) - http://www.msdignition.com/instructiondownload.aspx You probably need the adapter.

-

Just saw a comment by JohnC on zcar.com about "brinnelling" a bearing race (see Brinnell Hardness test). I think that it means damaging a race's bearing surface by pressing the balls in to it with too much pressure. Did you have any problems with installing the new bearings? Any chance that pressure was applied to the wrong race?

-

Are you using an adapter? Procomp is MSD, right? This might help you get your point across - http://en.wikipedia.org/wiki/The_Elements_of_Style

-

Aftermarket? That's all I know. Good luck with it. I fixed the link in my last post. Meant to connect to atlanticz's page.

-

There should be a letter - http://atlanticz.ca/zclub/techtips/cam/index.htm Your picture and description don't quite fit with the cam for an N42 head though. I think that the N42s had the spray bar and the N47s went to the internally oiled cam. No spray bar, plus pretty sure that I see an oil hole on a lobe. Maybe there was a transition period for the cam. Probably an A cam, either way, which seems to be one of the more popular stock cams. Anyway, someone will probably need it in a couple of weeks...

-

Every week or so someone is looking for a cam with rocker arms and towers. You could sell the head for those parts alone probably.

-

Have you checked all of the components using the 1983 FSM? If the swap was straight across, no modifications, from an 83 to your car, that would be the place to start. It shouldn't need "tuning" if it's stock. The pieces are designed to work together as-is. www.xenons130.com/reference Here's a popular swap link - http://forums.hybridz.org/index.php/topic/38461-240z-260z-280z-turbo-swap-guide/

-

Replaced Cap/Rotor - Runs Roughh

NewZed replied to RonK's topic in Trouble Shooting / General Engine

Some time with the Engine Fuel section of the FSM will save you and your mechanic a ton of time and money. Once the basics don't work, there's no better place to go next. An ohm-meter at the ECU connection with the FSM open will answer a lot of questions and probably lead to the source of the problem. You're at the head of the endless expensive path that many have followed. It's not a carbed small block chevy engine. It's easier than it seems, once you start testing things, it all makes sense. -

Replaced Cap/Rotor - Runs Roughh

NewZed replied to RonK's topic in Trouble Shooting / General Engine

RonK, I replied to your PM. As I said, he might looking at the vacuum advance switch, not the water temp sensor (WTS), since the WTS doesn't actually have wires, just pins. Easy to check at the ECU connector and worth doing. If the wires at the ECU don't give the right resistance for the temperature then you can look for problems between there and the sensor. -

Lots of good info but lots of iffy opinions also in that web page.

-

Replaced Cap/Rotor - Runs Roughh

NewZed replied to RonK's topic in Trouble Shooting / General Engine

-

If there's residual pressure after the clutch pedal is released I think that that means the rod in to the master cylinder is not coming back fully. It's adjusted too tight. It should have a small amount of play to allow the piston in the master cylinder to come all the way back, opening the port to the reservoir, relieving pressure. There's a similar problem occasionally described for brake master cylinders where the brakes slowly stop releasing and eventually lock up as the fluid gets hot. The master cylinder piston blocks the return port in to the reservoir, the fluid heats up and expands, brakes get applied.

-

Ground Control coilover issues

NewZed replied to 2eighTZ4me's topic in Brakes, Wheels, Suspension and Chassis

Sorry about that, I knew I shouldn't have posted. Good news for you. By the way, since the gland nut fits on the back tube, then the amount your guy cut off would be the difference in length between the original strut insert with spacer and the one that's in there now. Just sayin', math-wise, since the strut tube length has to match the insert length plus spacer (if used), after cutting, to get the gland nut to do its job. I'm done... -

Ground Control coilover issues

NewZed replied to 2eighTZ4me's topic in Brakes, Wheels, Suspension and Chassis

Just a neophyte's view - in Post #5, you said the fronts look perfect but Picture 4 shows only about 1.5" of shock travel, with no load on the strut. logr had the key comment I think, about stroke. The whole point of sectioning is to allow the use of a shock absorber (aka insert) in a position where the stroke can be used effectively. You're almost on the bump stops already. And in Post #1 you said that the BZ3012 was a 240Z front. It's a 280Z front for a stock setup, I believe. Maybe just a typo but could be important. Some of the Tokicos appear to be the same shock, just with different numbers, so it may not matter. Good luck with it. -

Replaced Cap/Rotor - Runs Roughh

NewZed replied to RonK's topic in Trouble Shooting / General Engine

Maybe this clue means something. Is the water temperature sensor still connected correctly? The wires are in the vicinity of the distributor, maybe it got knocked loose. Everything might be fine except it's running super rich because the ECU thinks you're up in Canada in the winter time. -

FS5W71C into 260z Auto to Manual conversion

NewZed replied to astrothedog's topic in Nissan L6 Forum

Here's another writeup for the 71C (300ZX) or 71H (240SX) case (bellhousing) swaps. http://www.motortopia.com/cars/1973-datsun-240z-11118/car-pictures/240sx-transmission-swap-14041/DSC04293JPG_Thumbnail1.jpg-266482 And from atlanticz - http://www.atlanticz.ca/zclub/techtips/240sxtransmissioninstall/index.html Here's one for the SR gear box, which appears to be the same as the 71C and 71H - http://forums.hybridz.org/index.php/topic/40643-tutorial-sr-gearbox-onto-l-series-engine/page__p__331608__fromsearch__1#entry331608 -

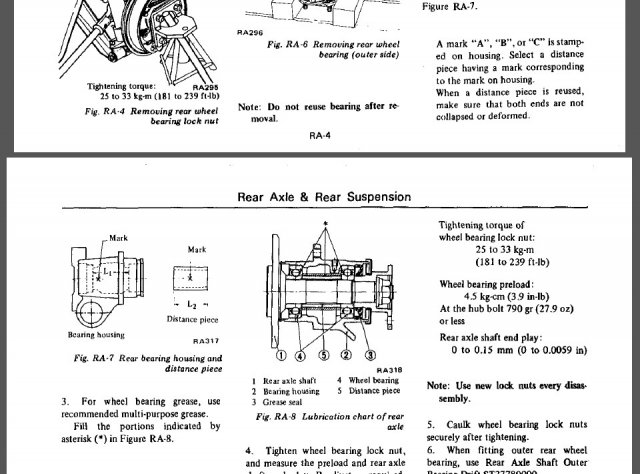

Maybe you got your "Distance Pieces" swapped. Check out this picture (for 1976 but probably the same) or the FSM, Rear Axle section, if you have it. The letter on the piece has to match the letter on the housing. By the way, if they were swapped, then the other side might have damaged bearings now. If I understand the drawings right, a short distance piece will allow the full 180 ft-lbs of pressure on the inner race, across the ball bearings to the outer race. Does the side that looks correct turn after tightening?

-

Measure from inner flange to outer flange on each side. The measurement should be the same. If there's a problem with the one with the shallow nut, it will be wider. Why is your thread titled "Half shaft issues" but you're discussing axles and companion flanges? Did you try the shaft and it's too long?