NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

Settling on two rear end options...

NewZed replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

You're covering a really wide range here. Including wheel hubs with your discussion of differentials. Talking about up to 450 ft-lbs of torque. That is a huge amount of torque. The R180 won't handle that if you get sticky tires and try to use it. The Ford diff setup is more appropriate for big torque but is a fairly extensive amount of work. As Ben280 says, it depends. -

-

Thanks for the observation? It works today. Maybe it's the Heisenberg effect. If you had tried earlier maybe you would have got the same message. Who knows...

-

-

Help diagnosing large amounts of white smoke coming out the exhaust

NewZed replied to jjslade's topic in Nissan L6 Forum

Might as well look at the spark plugs when you take them out for the pressure measurement. -

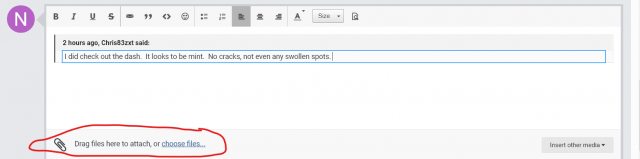

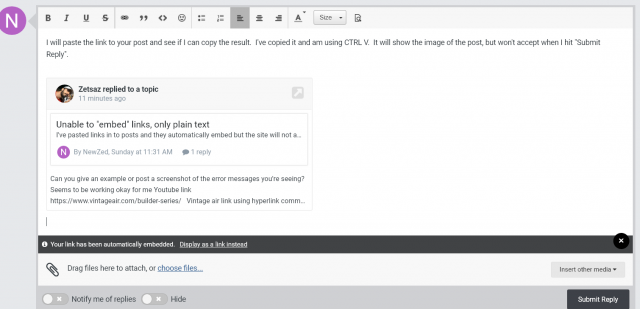

You can try it yourself by using the share function in the upper right corner then using CTRL V or "Paste" into your reply.

-

-

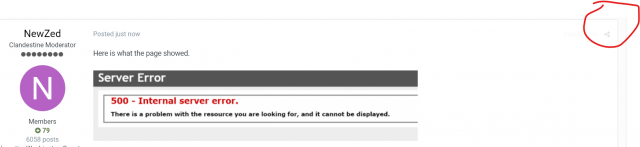

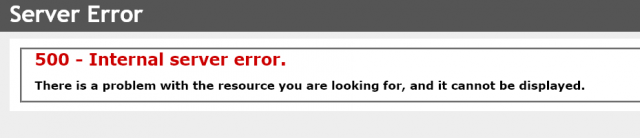

Here is the link to the web error page. I had to paste it then use "display as a link instead". https://forums.hybridz.org/topic/131711-unable-to-embed-links-only-plain-text/?tab=comments&failedReply=1

-

I will paste the link to your post and see if I can copy the result. I've copied it and am using CTRL V. It will show the image of the post, but won't accept when I hit "Submit Reply". So, it didn't work. I'll post the error message in my next post. It's what showed up after I hit "Submit Reply". I had to delete the embedded link to get this one to come up. Here is the image of what I attempted to do.

-

Help diagnosing large amounts of white smoke coming out the exhaust

NewZed replied to jjslade's topic in Nissan L6 Forum

Could be a cracked head. Check your spark plugs. They'll be a clue. -

I've pasted links in to posts and they automatically embed but the site will not accept the post unless I convert it to a plain text link. And the error messages have been different and unclear. I would guess that people have just quit inserting links or given up on posting links, because of this issue.

-

Wanted: S30 stub axle/companion flange. Or two.

NewZed replied to XplosiveLugnut's topic in Parts Wanted

240Z's have 25 splines, 280Z's have 27. https://forums.hybridz.org/topic/69569-240z-vs-280z-stub-axle-strength/ -

Underwhelming Lap Times

NewZed replied to Twisted46's topic in Brakes, Wheels, Suspension and Chassis

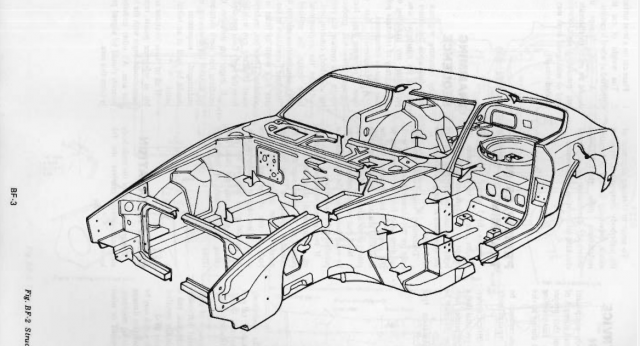

Don't have anything worthwhile to add but I can't remember if you have a 240Z or a 280Z. When I first got my 76 280Z I was surprised at how stiff the unibody was. Before I knew better I lifted from the back of the front frame rail and could get the whole side of the car up with no apparent flexing. I was used to old chevys that creaked and groaned and bent as you lifted them. The difference between the 240 and 280 bodies is often a topic of discussion. -

ignition Anyone else using FAST EZ EFI? Help

NewZed replied to Shiboh's topic in S130 Series - 280ZX

The O2 sensor signal is used by the system to adjust the open-time of the injectors. Impedance will not have an effect on the feedback signal. No offense to you guys but you should study up on how EFI systems use the O2 sensor signal. It's called "closed loop" control. It's still not clear how long people are waiting before they decide something is wrong. You need to let the system stabilize. Efforts to fix things before the system is stable just causes continued instability. Still, both FAST and zcardepot are selling kits with poor instructions and explanation of how things work. I wouldn't buy one for that reason alone. The FAST site is full of hype with very little support. Their forum function doesn't even work. I think that they're just milking the market until they die. http://www.cpgnation.com/forum/#technical-faqs-reference-articles.85 -

I found it. I was more talkative back then. Some good comments from other members though. Having problems posting, this is a test. The site would only take the lin, as a link, not embedded. Weird. https://forums.hybridz.org/topic/116305-torsional-rigidity-testing-280z/

-

I think that they're showing "boxed" body components. Integral reinforcement as you said. Like the rocker panels are one of the most important structural elements of the unibody. People often overlook that area when dealing with rust. The "frame rails" are just added stiffeners. They'll replace the stiffeners and leave the rusted out rocker panels. So, when looking at the cowl, or any body area, look for those reinforced areas. But, I'm not a structural or automotive engineer, so don't put too much weight in to my words. Somebody had a thread on the site where they really went deep in to how to reinforce the body. I think that they even built a framework to load the frame and measure deflection. It might be in an FAQ area, or might be found by a search.

-

-

At least I get the satisfaction of realizing that my intuition was right. I saw the first post and thought that I might not enjoy a dialog with the poster. But I took a chance, to see which way things would go. Could easily have gone the other way, with acknowledgement, a simple clarification, and offering some ideas. Oh well. I miss those old days. Good luck JMort.

-

Sorry. I have the disadvantage of too much good schooling, I guess. Proper grammar would be "engaged/disengaged smoothly". Not "completely smooth". My over-trained brain was expecting different words. Never mind. Too early for word battles. Good luck.

-

I can't figure out what the heck you mean. Could you add some words? p.s. "engaged" is clutch pedal up. "disengaged" is clutch pedal down. But you still need to add some descriptive phrases also. When, exactly, do you hear the clunk/knock?

-

The triggering mechanisms are the same on the ZX distributors. The different distributors have different timing curves but work the same at idle speed. When a spike passes a spike a voltage pulse is generated. By "compare" I meant to set them side by side and see if the breaker plates and other moving parts are in the same orientation. Sit and stare at them for a while. Set them up so that they should be in exactly the same position and see if the spikes are oriented the same way. You can use your engine for that also, install them both, one at a time and take a picture of the reluctor spikes and trigger ring spikes. They'll probably be different. Then find a way to make the new one look like the old one. The oil in your engine should be below the level of the rear seal. No reason to create a puddle if the seal blew. But, no reason for the seal to blow from an engine "cough" through the intake manifold unless it was barely seated. So that is odd. Your clutch should be fine, it's on the other side of the flywheel. Thousands of leaky seals out there. At least you have something to do that doesn't require getting out and about and exposed. Good luck.

-

ignition Anyone else using FAST EZ EFI? Help

NewZed replied to Shiboh's topic in S130 Series - 280ZX

You just have to pull bits from a variety of past stories. Basically you have to tune it to within a certain range, then let it "learn". I think that their target market is people who buy this and have a tuner install it. http://www.cpgnation.com/installing-a-fast-xfi-system-in-a-1964-fuel-injected-hemi-dodge/ If you can get the ECU closed loop correction under five percent, you’re good to go. Richard targeted 12.8 for the max power A/F ratio and the fourth pull resulted in this setup. -

ignition Anyone else using FAST EZ EFI? Help

NewZed replied to Shiboh's topic in S130 Series - 280ZX

Their support page has a lot of broken links. http://www.cpgnation.com/fast-quick-tech-video-installing-the-ez-efi-2-0/ -

ignition Anyone else using FAST EZ EFI? Help

NewZed replied to Shiboh's topic in S130 Series - 280ZX

There's a process, but it's not clear what it is. Megasquirt has a "learning" function also, in case anyone wonders. http://www.cpgnation.com/inside-the-fast-xfi-2-0-hardware-and-software-tuning-features/ "The Self Learning VE table works by looking at your target air/fuel table and your base VE table and comparing the two, creating an automated VE map for your vehicle. Through the use of a dyno or normal street driving and with a wideband oxygen sensor and closed loop tuning, a ballpark fuel table can be created in short order. This obviously isn’t meant to nor can replace human input, but it will certainly get you a base to tune from. And for those jumping from the street to the strip and back, this is a great tool."