NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

-

Roberts280Z is correct. It's energized by the top gear switch. For some reason, maybe emissions or knocking reasons, Nissan did not want the vacuum advance to work in the lower three gears.

-

Dyno and u-joint replacement advice

NewZed replied to jkelly's topic in S30 Series - 240z, 260z, 280z

Sometimes they're hard to see, especially if they're covered in greasy dirt. The plug has a thin head with a slot for a screwdriver. Should be here. This picture shows the hole still open. -

Only lights working on 280z are blinkers

NewZed replied to rjwill's topic in S30 Series - 240z, 260z, 280z

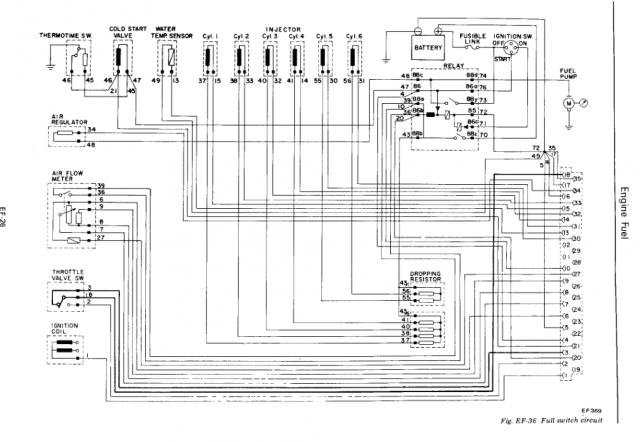

Under the plastic steering column cover there is the switch for the headlights and the running lights. The solder joints break pretty often. when you ran the hot wire you bypassed the switch so that's a clue. The wires on the top are where it breaks. Talking about red wires and black and white wires kind of shows that you're not using a wiring diagram. You should get one. It will help. 76 is probably close if you can't find a 75. There are small diagrams in the Body Electrical chapter. http://www.atlanticz.ca/zclub/techtips/electrical.htm https://www.classiczcars.com/files/category/1-wiring-diagrams/ https://www.classiczcars.com/files/category/13-280z/ -

Dyno and u-joint replacement advice

NewZed replied to jkelly's topic in S30 Series - 240z, 260z, 280z

The u-joints can all be lubed. They might not have a Zerk fitting but they should have the hole with a slotted plug in it. Take the plug out, put a Zerk in, fill them up, and put the plug back in. Inspect the seals and seams closely for rust or looseness. If you do find a bad one, just replace the one. I found that the new aftermarket joints were looser than old Nissan joints. -

Dyno and u-joint replacement advice

NewZed replied to jkelly's topic in S30 Series - 240z, 260z, 280z

The Nissan u-joints are of very high quality. $80 each, with precision clips to ensure an exact fit. If they're not dried up or rusty, why replace them with $20 u-joints? The R180 will probably blow before the u-joints. -

ignition Anyone else using FAST EZ EFI? Help

NewZed replied to Shiboh's topic in S130 Series - 280ZX

They're 188 mL(cc's), at 3 bar, apparently. The design is licensed from Bosch, the Bosch 280-150-105 injectors are the same and often used in place of the factory injectors. http://users.erols.com/srweiss/tableifc.htm http://www.atlanticz.ca/zclub/techtips/injectors/index.html -

ignition Anyone else using FAST EZ EFI? Help

NewZed replied to Shiboh's topic in S130 Series - 280ZX

You could use dropping resistors with the stock injectors. I don't know what's in the zcardepot kit, but that should allow their use. -

Check the hoses to the core in the engine bay at the firewall and the return line to the front cover. Also check the back of the head where it meets the block. The HG can leak there.

-

I don't know why Rockauto even has that AC Delco switch on that page. They are slipping. The description is all wrong for the car, even the brand. The Beck Arnley should work. It's a sensor.

-

You should put the part numbers or links in to your post. Nobody knows what you actually worked with. The hole is BSPT. After 1977 the sender was combined with a switch. Those parts has two terminals. One terminal is the pressure sender and one is the switch. You can use that on your 76 and just leave the switch terminal unused, if you already have one. Beck Arnley has been supplying Z parts for years. Their sender probably works. If I was starting from zero I'd go with that one. It has the best odds. p.s. make sure that you use a thin wrench on the flats to tighten it. Don't try to turn the body it will break loose, spin, and damage the guts. https://www.rockauto.com/en/catalog/nissan,1976,280z,2.8l+l6,1209226,electrical-switch+&+relay,oil+pressure+sender+/+switch,4588

-

That "shell7" link I placed above is a page of the JTR web site. https://jagsthatrun.com/collections/datsun-z-parts

- 13 replies

-

- companion flange

- driveshaft

-

(and 1 more)

Tagged with:

-

The R180's have axle holes surrounded by five bolts. The R200's don't. For some reason I can't figure out the side view that you showed, the axles are in shadow. Also the R200's have a rectangular chunk of aluminum on the bottom of the diff cover. Your second picture seems to show it but it would be upside down. Can't see the drain plug to know what's up or down. It looks like an R200 but those are bad pictures.

- 13 replies

-

- companion flange

- driveshaft

-

(and 1 more)

Tagged with:

-

This might help. https://shell7.tdl.com/~jags/Pages/Parts_DAT_driveshaft_flange.html

- 13 replies

-

- companion flange

- driveshaft

-

(and 1 more)

Tagged with:

-

What years 280Z? The 75 280Z's had R200's with the same pattern as the later 300ZX's (I thought..). They were oddballs. Check your driveshaft u-joints to see if they are removable, look for the internal clips. 280Z's had staked u-joints, not replaceable without machining. Here's some part numbers from an old thread, below. I'm not sure what's what in the thread, I thought that the 75 280Z parts would fit the 300ZX diffs. Not sure which if these is which, but it shows where your problem probably started. You'll have to do some more searching and checking of your parts. https://forums.hybridz.org/topic/113866-280z-r200-differential-pinion-flange-wanted/

- 13 replies

-

- companion flange

- driveshaft

-

(and 1 more)

Tagged with:

-

This is reasonable. Worth checking. Don't make decisions based on assumptions. Make the assumption then check to see if it's happening. Is your tachometer needle behaving normally? Does it seem like spark is happening correctly?

-

I don't think that you can say this with certainty.

-

Just curious, but many people have mentioned looking at your diagnostic data. Is there some reason that you're not? You're obviously able to change the settings, you changed the injector values. If you look deeper you might find something. So far it's just been guessing about a clicking noise. If the injectors are dumping fuel you'd smell in the exhaust and see it on the plugs. Are you seeing signs of running rich or assuming that it's rich. I remember on my 76 when the idle got too low the fuel pump relay would cut fuel and the engine would stumble until I hit the throttle to raise idle speed. In the cabin you'd hear a bunch of clicking noises. Maybe the clicking noise is a relay or two and not the injectors. Keep looking. Good luck.

-

How about the pickup tube? Could be clogged or maybe it even fell off? If you took the filter off and nothing came out, you're pretty much at the first place to look after the pump. I don't think that system is complicated. Don't know. Good luck.

-

You might put a mechanical gauge on the pressure sender port to be sure about what you think is happening. Or just remove the pressure sensor from the block and crank the engine over. If you're right, no oil will come out. If you're wrong, there will be a mess. Just a simple test to be sure you're on the right track. Also, are you sure that your drill motor is turning the correct way? Counterclockwise would be reverse on a drill motor.

-

There are too many pages and I haven't been following, but does your EFI system have any feedback or measurement tools? A "dashboard"? You might be able to pull up injector open duration and see if it's out of whack. That could be an input signal problem. If you have an oscilloscope you could probably measure actual injector open time and compare with the ECU's programmed duration and look for mismatches. Stuff like that. Just spit balling. I'd check your EFI system capabilities though, some of them are pretty sophisticated.

-

Good luck. Beware the vague terms like burnt or overpowered. With electricity there are two very basic things - breakdown voltage and over heating. Breakdown voltage is when the electricity just "blows through" the insulation, due to voltage over the limits of the insulation, to short circuit to ground, or to the next wire over in an injector. Overheating is what happens when too much current passes through a conductor and creates more heat than can be dissipated over time, which can also damage insulation. With injectors the insulation between the windings is the same for low or high impedance. They both use 12 volts. Peak and hold "peaks" at 12 volts then drops to a lower voltage to hold at a lower current. It doesn't start at a lower voltage. The biggest beware is to know that many of us are just Googling, or guessing. Injectors are pretty durable devices. The odds are very low that your EFI system damaged them. The injector companies will gladly sell you a new set while you try to figure out the true source of the problem. A meter is your best friend. You don't have to be an expert to measure the basic stuff.

-

But the system would send less current if you had them set to low ohms. Your high ohm injectors can't be overpowered by any of the injector settings. If you had set low ohm injectors to high ohm, maybe. You could pull the connectors and measure resistance with your meter.

-

The injectors are cooled by fuel. Seems more likely that the injector control transistors would get damaged. But if they are high ohm injectors then they should be more safe if you set them to low ohm. Besides that the power pulse is very short. I don't really think that you can damage injectors with an incorrect impedance setting. Your transistors are probably fine too, they don't see much current. Your problem is probably something else, I'd guess.

-

280zx (1983) shocks and springs, anyone?

NewZed replied to supernova_6969's topic in S130 Series - 280ZX

You should always get full weight on the suspension and roll the car back and forth before evaluating changes. Make sure the shocks aren't binding by moving the car up and down. And consider tire size, a smaller tire will lower the car but make the gap bigger in the arch. Best to measure from the rocker panel to the ground if you're talking about lowering. Don't blend lowering with tire gap. And drive over a few speed bumps slowly early on so you'll know what's going to scrape later.- 23 replies