NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

Nearing the end of the rope on my 280z (text heavy)

NewZed replied to SoCal'77's topic in Trouble Shooting / General Engine

List the numbers that you got from the "bible" tests. Coolant temperature resistance versus temperature (measured at the ECU), fuel pressure with and without the vacuum hose connected, ignition timing, etc. Describe what parts are on the engine now, AFM (is it the right part number), distributor, ignition module (is it the stock 1977 unit?), PCV system (all of those hoses on top and under the intake manifold) complete and properly connected, etc. Then describe n detail, with numbers like seconds or minutes, what the problem is. "It dies then takes 30 seconds of cranking with the fuel pump off to start" or similar, whatever describes the situation. Engine dies, won't start is too vague. The EFI system has a lot of parts and they are all connected, and need to be working right. Any one of the things I mentioned above could screw up the way your engine runs. -

They all do. It's normal.

-

Nearing the end of the rope on my 280z (text heavy)

NewZed replied to SoCal'77's topic in Trouble Shooting / General Engine

This is completely wrong. Seems like you've got the skill with hand tools but you don't understand how electronic fuel injection works. No offense, but that's what you're showing. It's important to know at least the lowest basics to make these things run right. The Engine Fuel chapter of the FSM does an excellent job of explaining how the system works. You gotta read it. The fuel pump is on all of the time that the engine is running. If you take an 8 hour drive, the fuel pump had power and pumped fuel for a solid 8 hours. -

Nearing the end of the rope on my 280z (text heavy)

NewZed replied to SoCal'77's topic in Trouble Shooting / General Engine

Slapping is generally a bad idea. A loose distributor shaft won't cause your tach to "go nuts". EFI with a return line on the fuel supply doesn't vapor lock. Fishing around isn't necessary when the full FSM is available through the internet with detailed diagnostic procedures. You need to find a full size screen so you can do some study. Get a meter and open the FSM and generate some numbers that tell you something. -

Many old L28 EFI systems are lean. For whatever reason, old electronics, or today's fuel, adding resistance to the coolant temperature circuit can fix the problem. Actually, it seems that Nissan might have set the EFI tune on the edge initially, especially for the ZX's, for mileage or emissions reasons maybe and now it's too lean. It's not uncommon to find a resistor in the coolant circuit wiring on an old ZX. Many people add a potentiometer to tune on the fly. Search for BRAAP's EFI tips in the L Series FAQ's and you'll see it described.

-

Nearing the end of the rope on my 280z (text heavy)

NewZed replied to SoCal'77's topic in Trouble Shooting / General Engine

Signs do point to the ignition module (stravi's power transistor, there's one in the module). "my tach would go ape-shit". The noise from the fuel pump relay is what happens when the engine is about to die. No air through the AMF to keep the pump contacts closed. You've done so much work on it that it's hard to tell where to focus, but, if you're desperate, wire in a GM HEI module, for ~$20, disconnect your stock module by the fuse box (insulate the wire ends so you don't get a short), and see what happens. It's a fairly common problem, the tach behavior and the fact that it revives after cooling down are signs. But, search around on HEI module swap for 280Z's first and see what you think. -

I'm new and would like some help with I.D.

NewZed replied to I just don't know's topic in Gen I & II Chevy V8 Tech Board

The Service Manual is full of drawings, very well-done. The internet is full of pictures. Even a car with intact original parts is a complicated project. More help - Body Electrical chapter for the links and those parts. -

Nearing the end of the rope on my 280z (text heavy)

NewZed replied to SoCal'77's topic in Trouble Shooting / General Engine

Bear. Should have joined about $1000 ago. You've described the past, but there's not much about the present. What is today's problem? All I can get is sometimes the engine dies when you shut the door. -

I'm new and would like some help with I.D.

NewZed replied to I just don't know's topic in Gen I & II Chevy V8 Tech Board

Those used to be connected to the fusible links. They power everything in the car. They're needed. Here's an easy link to the Service Manual - http://www.nicoclub.com/datsun-service-manuals -

I posted your Facebook work in Post #4. It references 240 and 260, but no 280. Hence the darkness about 280Z's. It just seems odd that Nissan would add the R200 option to the S30 cars and create and leave in place a new problem. Since they changed other stuff at the same time, it's not clear if they missed something or not. Someday, I'll get a 240Z and do some measurements. Or check for binding when i have my 280Z apart again. It's working too well to take apart right now.

-

What goes up usually comes down. New diff mounts actually have a little bump of rubber in between the metal pieces to absorb the shock, The stuff after "Since" doesn't quite make sense.

-

The later one is probably shorter from top to the collector flange. Take a measurement. It should fit the head but the exhaust pipes will be too far away, and and not aligned correctly. You'd need to do some pipe work.

-

The problem, if it's real, is probably more noticeable with stiff bushings, like polyurethane. The stock rubber bushings would just deflect outward, most likely.

-

All I have are 280Z parts. So I went to the only other source available, the FSM, and compared engineering drawings. I don't have the software to manipulate these images the way I'd like but I think that I was able to match the bearing race sizes. And they seem to show that the 280Z flange and axle assembly is actually slightly narrower than the 240Z. It's not dramatic at all but might work out to a few millimeters in real size. I'm not trying to make a case for anything, just trying to figure out what's different. Feel free to take some shots. I used a caliper to compare images on the screen and resized them until the bearing races were the same diameter. 1976 drawing on top, 1972 240Z bottom. Note that you have to measure to compare flanges, the 240Z image is offset to the right.

-

That is my proposal. Assuming that track width and wheel offset are the same, that's all that's left. Or the 280Z's bind also, but nobody has noticed it.

-

Saw some of your other posts but can't remember if you knew this one or not - http://www.thezstore.com/page/TZS/PROD/11-2995

-

Cylinder Head Temp Sensor question(L28ET)

NewZed replied to rickyellow zee's topic in Trouble Shooting / General Engine

Not butt-hurt, but amused (that's an intentional pun). At least you have a page number now, although it is after the fact. -

Cylinder Head Temp Sensor question(L28ET)

NewZed replied to rickyellow zee's topic in Trouble Shooting / General Engine

Faking to try to get his answers? We all used to do that when we were kids. Or it could be a reading issue. -

Cylinder Head Temp Sensor question(L28ET)

NewZed replied to rickyellow zee's topic in Trouble Shooting / General Engine

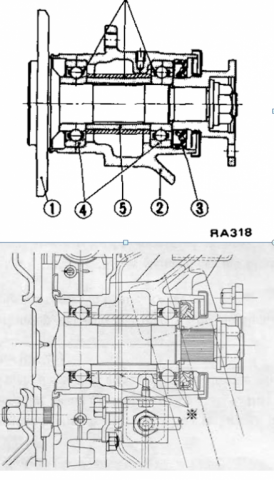

Pretty well described in the FSM. Can't go wrong looking through that, it's like a school book. -

I don't have the parts to confirm it but, assuming the wheel track widths are the same, 240Z and 280Z, the only thing left is the companion flange depth. The 240Z companion flange must stick inward farther than the 280Z flange.

-

simplicity and reliability, ZX turbo track toy

NewZed replied to stupid_fast's topic in S130 Series - 280ZX

Looks like a two car demolition derby. Have fun with it. -

You were clear. It's a self locking nut on a stud with either a washer under it or a flanged clamping area. Designed for zero movement once it's torqued to the proper spec., locking the bar to the diff cover. The size of the hole is not a big factor unless it's so wallowed out that the nut and washer is slipping inside. Take it apart and remove any burrs on the clamping area, clean all grease/dirt/oil from those areas, including the flat area on the diff cover. Put it all back together and torque it down. A clean, dry surface with good surface contact and it shouldn't move at all. Burrs, dirt, defects, with lubrication, will allow it to move and the nut loosen.

-

simplicity and reliability, ZX turbo track toy

NewZed replied to stupid_fast's topic in S130 Series - 280ZX

It's only been 17 minutes. Drift is an odd freak show kind of entertainment. Not like modifying a car for handling and performance. They're two very different areas of expertise. -

The torque spec. is 54 to 69 ft-lbs. Not enormous but more than snug. The only play should be what the bushings allow.

-

First - click on the Continue Reading link. Then continue reading.