Leaderboard

Popular Content

Showing content with the highest reputation since 02/06/26 in all areas

-

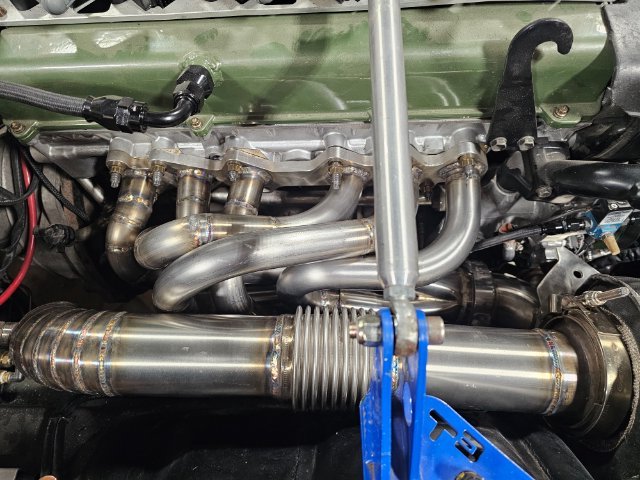

Looking GREAT!! 👍👍 I really like the metalwork....makes you look like a skilled Italian craftsman (whereas mine makes me look like a one-armed monkey with a rock and a baseball bat.)2 points

-

2 points

-

2 points

-

HybridZ is now 26! It's too old to remain on its parents' health insurance plan, and now needs a real-job, with benefits and maybe even a 401K plan. Anyone left here, who started working on their V8 Z project back in the 20th century, and is still wrenching on it? Anyone?2 points

-

I know how to close the ads 😄. And I don't expect entirely ad free. I do as a user don't want 80% ads though. And agreed there is cost involved, not doubting any of that. There is no such thing as a free lunch as they say. Guess we are all constant problem solvers 🤔. My only thought isn't so much from a how do I block ads, but I know hybridz gets referenced all the time on Facebook groups and Reddit. If I was a new user and didn't happen to have adblock setup, I definitely wouldn't sign up because nothing looked legit. My .02, appreciate y'all listening and I'll go back to my own problems 🤣1 point

-

Tap the arrow on the drop down ad and it will collapse. Then just scroll down. I too lament how prevalent ads are on the internet these days, but Dan has to pay for the server somehow. I like the membership idea. The merch campaigns always bring in a ton of money, but that takes a lot of work from whoever is organizing it.1 point

-

1 point

-

Thanks jhm — appreciate the honest response, and totally understand the bind. Obviously, I'm shooting in the dark here. I don't know the traffic, active users, new users etc. Firstly: you are correct, ad block exists. I could do something like that for mobile too just like desktop versions. Out of curiosity, has there ever been any thought toward a paid ad-free tier? Honestly, if it was under $5-10 a month I'd sign up today, I pay $9 a month to Skooler.com, I've used it once, but have never bothered to cancel the membership. Feels like there might be others who'd rather pay a small amount than fight the ads, not a one time donation, but an a subscription and a badge. Are the ads currently through something like AdSense, or do you have any direct vendor relationships? I can't help but notice a Ford Mustang dealership ad on a 280ZX forum and wonder if there's a more Z-relevant way to fill that space. Not trying to armchair quarterback, just genuinely want to see this place thrive. Self Acknowledgment: these things could have been tried during my time away and that is on me.1 point

-

1 point

-

I just posted this to ZCAR: “Receiving periodic/automatic emails that say: ‘Come back, we’ve missed you!’ Sometimes life gets busy enough that I forget to login. I appreciate getting occasional emails reminding me of this great resource. I also think it helps keep the involvement up in the forum. Excellent idea. Thank you.”1 point

-

02-26-2026 ATLAS Z UPDATE: Today I got my rollbar and rear strut brace back from the powdercoater as well as the tunnel I dropped off to sandblast. The rubber is still on there, but this yucky sticky layer of honey look goos (glue) is gone. I also picked up my trans mount, he welded it up and added gussets on both sides out of 1/4" plate. I painted the back side quickly before I ran out of paint. Ready for the next day in the garage! P.S. self tapping screws and sheet metal (18 ga) here and ready to built it back, then the welder will stitch weld it and weld the plates over the top and over on both sides to the door jambs. 1/4" thick, 4 inch wide plate. Car will be overbuilt int his area like I did with the radiator support. 350-400 horsepower you really have to, even with the reinforced floor I have.1 point

-

this is very cool, I will be following along. Love the custom work. I am doing a 1jz swap myself at the moment so nice to see another with another person fab ideas1 point

-

1 point

-

😅 hopefully the only thing looking this good is the front. Ill leave the rest looking abit rougher. Really wanting to pull it out this year and at least drive around the block1 point

-

02-18-2026 ATLAS Z UPDATE: picked up my 1/4" thick steel plate for making the transmission mount, set out my seat belts for cleaning, and my rear strut tower brace from Apex and a Autopower Street rollbar from Motorsport Auto have arrived. So, I will decide what color I want to powdercoat stuff (gloss black of "polished aluminum") , and keep pressing forward. Will be COLD for a few days, so any work done will be indoor stuff. PICS:1 point

-

8th build? Wow! I'm still nursing my first (and only). Car has been on the road, and off. Registered, and not. The current iteration is "not". I need help - local help - with the care and feeding of the engine. The real problem isn't with the Datsun parts, but the Chevy parts... namely getting that darned engine to work properly. Seems like a simple problem, no? But nothing is simple these days! Also, the exhaust is too loud, and the transmission is geared wrongly. I need a custom re-welding for the former, and to write a check for the latter. I also need an engine hoist and a place to work on the car. Success with hobby-cars, begins with success in real estate!1 point

-

02-14-2026 Happy Valentines Day! Today I got the transmission in. Took a long time. I left the pilot bearing in the freezer overnight, and I was able to tap it in easy. After I installed the clutch and made sure to use the ARP lube on the bolts, I started prepping the trans tunnel. I had to cut off the factory trans ears and grind them smooth and gave them a quick coat of paint. Then the hard part started. After trying and trying, I realized the trans tunnel just wasn't going to let it happen.....so I started cutting it out from the firewall back about a foot or so, then more and more..... little at a time, as I needed the room. I did keep the pieces cut out, As I will cut and modify and have a mobile welder come and weld them back in AND while here weld a thick steel flat plate about 3-4 inches wide the trans area and passenger floors to add more reinforcement for the power level of the engine. I was able to use a floor jack and level the engine up, and now you can see in some of the pics, what it looks like level.....yeah, dusty but you can still see it. My center console will be modded with the center floor cut out leaving a small ledge on both sides so I can make a custom aluminum floor. The shifter mechanism will be left fully exposed, I love look. It makes the shifter throws SO SHORT! So, big day. All in, now need a trans mount underneath that will bolt through the floor into plates to hold it, the reinforcement plates across, and eventual console mod. I got VERY dirty! Cheers! PICS:1 point

-

Hi all, I'm new to HybridZ. I'm looking for information on the best parts to pull from a donor car I just picked up. My 240z and the 1982 280zx donor are in the pics. The donor car is complete and the odometer shows 71k. My plan was to pull the full drive train and swap it into my '72. I will save all the parts from the '72. I want to keep the car all Nissan. So, for the motor, is it worth keeping the fuel injection? I have also seen something about using custom brackets for the rear disk brakes. After I have picked what I want the rest will be parted out. Thanks for looking and good info. Bill1 point

-

02-11-2026 ATLAS Z update: I got back half of the car all wired in except for a license plate light I am waiting for it to arrive. pretty cool LED unit I found on Amazon for 8 bucks. Got the headlights almost in. I always have a problem with this job. I had to break out the angle grinder and mod to get the driver's in....unsure so far far with the passenger one. Strange..... it REALLY fought me. I also got the 10AN line between my main filter and pump in, so it is ready for installation. PTFE lines take some work.1 point

-

Thank you. a bit overkill but im happy with how it came out. I hadn't planned on making them but no reason i can't. I can get some material and when i get some down time i could make another one.1 point

-

up here in the north east we get some great fall scenery for cruising but can get a bit chilly so the heater will be used for that aswell. but the defroster on a raining track day will be important. Thank you. love being creative during a build.1 point

-

Happy Birthday HybridZ. I’m a little over one year into my V8 track build, this forum has been very helpful 💪1 point

-

Well Happy Birthday to Hybrid Z !There is still plenty of time to keep playing! What a great forum it has been. Thank you for those who help keep it going! I'm close to the 20th century (2004) since i started on my Z. Still going strong1 point

-

Second Owner of the SEMA SHOW Toyota A86 Body The First Owner of the SEMA SHOW Chinese Made Copy of the Toyota A86 Body decided to sell the body. The real question is why? The next Owner bought it with the idea of attempting to assemble the body and create a drivable car. As the body has No VIN Number and No Manufacturer ID Number, they knew that car registration in most states would not be possible. They intended to use this body as a Race Car as no registration would be necessary. As the video demonstrate that most mounting holes that not align with OEM parts. Also, they discovered a lack of sufficient welds on the body panels. Mounting brackets were missing or mislocated. So even if it was going to used as a Race Car, major welding and reinforcement of the vehicle would be necessary. So far, there has no one that I know who purchased a 240Z body from this same manufacturer. So far, we could not get a firsr hand through inspection of the Zbody and find if that body is manufactured better or not.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

FWIW, I have a ZTrix hood on my 2X Nat Champ EP car. It weights 10 lbs and was weighed with an accurate scale. I asked John Washington to lay this up with weight in mind. The hood is sufficiently stiff and doesn't have any CF in it. It's pretty surprising really. I bought some more of these recently with John and they weighed 13.5 lbs. I assume this hood would work properly with the front torsion mechanism on the stock Z, but we don't use that or the rear latch. Hope this helps. Greg Ira1 point

.jpg.b34f27553f5960421801c8ab2cbf5db3.thumb.jpg.7889e8073010b6a0d8d6aae0626e768b.jpg)