-

Posts

336 -

Joined

-

Last visited

-

Days Won

10

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Exposed

-

great job on the fabrication! What thickness of aluminum did you end up going with?

-

had some time this weekend pulled the engine out hopefully for the last time. With the engine pulled I had alot more space to patch some of the rust. Going to start patching up the firewall covering up some of the holes I wont be needing. Glad with all the progress I've made this far, cannot wait to have it finished!

-

A musician's therapist (The $300 Z)

Exposed replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

Looking for help isnt always the easiest thing to do, good job on seaking some! What pump are you going to be running? I'm looking at redoing my fuel system as well this winter/spring but still in the planning stages. I had picked up a Bosch 044 and didnt really want to swap it out for something else. Are you going to be running the stock fuel level unit? -

Welcome to the forums! @Huntziilla -Was the engines compression checked? Youll need a rear sump because of the front cross member. Are you dead set on going with the R154? Have you considered any other transmissions that may be cheaper? -When I swapped my 1jz into my 72 the only specialty tool I used was an engine hoist. -Are you planning on making your own engine mount? Up in Canada you can find an almost identical Jaguar mount at princess auto, which I beleive is similar to habour freight, and they sell for about $10.00 CAD for two. -Looking at the link it looks like the engine wiring harness is there. Cannot see if its cut anywhere though. Hopefully someone can correct me if im wrong here but I would look at getting the ignitor and Map sensor included with the engine. I know when I purchased my 1jz it wasnt included and I did require it. -While the engine is out depending on mileage, I would probably open up the valve covers and look inside of the oil pan just to see how everything is looking. I'd change the belts and potentially do the water pump at the same time. Still waiting on picture of your car!!

-

@HuD 91gt I'm glad to hear that Im not the only one in this boat.

-

@walkerbk 👍 thanks for the link, Ill check them out. Im dreading the wiring again 😅, wishing I had done it well enough the first time.

-

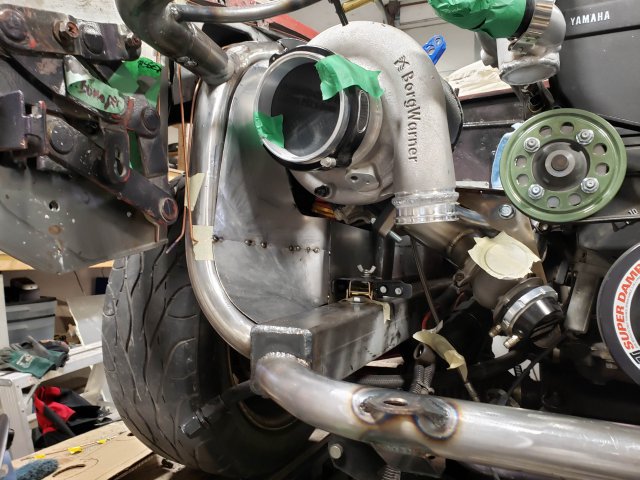

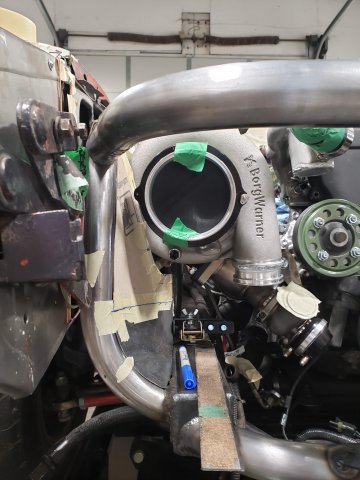

Awhile back I made the panels that attached to the hood hinge, when I bead rolled them I didnt account for the shape of the hinges so when I mounted the hood hinge it over top of part of the bead roll design. Normally I would just leave it but for some reason its been bugging...the old lady says im crazy. Ended up make "version 2" of that patch panel and I think Im happy enough with how it came out. Started working on the cold side piping for the intercooler as well. I ended up printing out some pie cuts to see what type of centerline radius would fit best, ended up using a CL radius of 3.5". If anyone needs any STL or gcodes on pie cuts let me know! Been looking at electrical connectors and I've seen people using Mil Spec, does anyone have any other recommendations?

-

Heavy Duty frame rails and connectors

Exposed replied to toolman's topic in Gen III & IV Chevy V8Z Tech Board

great job! really enjoying this build -

Frame rails too far gone to repair?

Exposed replied to ZigzagZ's topic in S30 Series - 240z, 260z, 280z

I have to agree with idahoskiguy, for the pictures posted I cannot see the car being worth 8500. I can only imagine what is under the paint.- 11 replies

-

- rust

- frame rail

-

(and 1 more)

Tagged with:

-

@LLave 😂 its funny how that always seems to be the case

-

starting to come together again! After this past week I've been motivated to get it finishe d, still plugging away on some filler panels. Lined up the fender and headlight bucket, needs a bit of fine tuning but luckily I'm not the pickiest person in the world. Would be nice to have it on the road by spring.

-

-

-

looking good, great use of the 3d printer.

-

-

Had a bit of time on my hands two weeks ago, had been waiting on the old ladies water to break. I have a headlight bucket that has seen better days, decided to try something different out, I couldn't source anything newer. Current prototype print is PLA settings are 210 at the nozzle and 60 at the bed. 20191125_235035.mp4 also got a bit more practice laying some beads as well, this is for a 59 chevy.

-

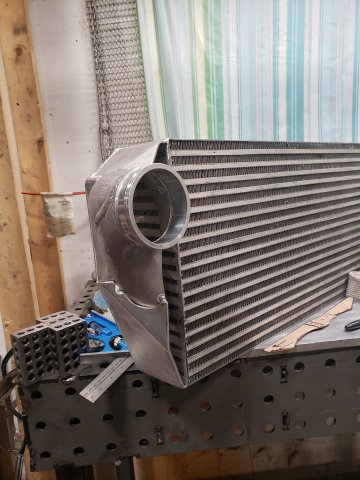

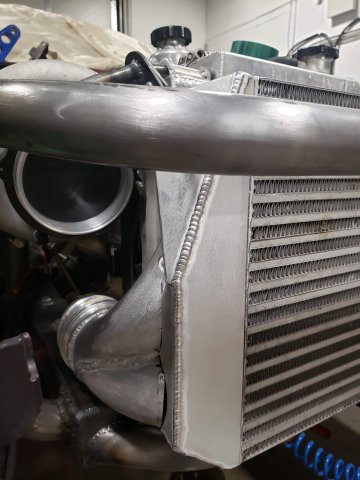

finished up the passenger side end tank and also finished the upper radiator hose connection. I 3d printed a couple dies for my bead roller and put a bead on a piece of 1.5" dia. tube, tube was cut from 90.

-

Yes I crossed over while in the trans tunnel, will probably do the same thing when I get to that point. Currently have the entire setup done with soft lines and brackets.

-

i ran my lines near the top of the trans tunnel then routed them to the "cold" side of the engine. When I redo them again Ill probably build a heat sheild with a bulkhead connector

-

Looking good 👍

-

-

finally found some time to begin working on one of the intercooler end tanks, mocked it up in CAD before starting, then got to work.

-

Need wiring help - 2JZ GTE direct ignition coil packs on GE

Exposed replied to M_Dragan's topic in Toyota L6 Forum

might be different for the 2jz but on my 1jz I still had my soarer igniter when I swapped coils. Everything worked well while I had the stock ECU. Everything remained the same once I swapped out the ecu for an AEM infinity. Hopefully someone with more knowledge is able to chime in. -

any build pictures? Looks like a good looking car.

-

@Zetsaz yup, that's awesome