NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

Clicking/ticking is the common bad CV joint noise. On front wheel drive cars you hear it all the time as they turn. You said that you had an R200 and CV axles and replaced it with a different R200 (the CLSD) and a different set of CV axles. Seems like you could put the other CV axles in, and give it a short test drive. If the noise stays it's probably the diff. If not, you damaged some axles.

-

If you can't see the plate on the top look at the area around the speedo cable. Here are two pictures I took a while ago of my 76 4 speed and 78 5 speed. Trying to find a way to tell them apart from below. The 78 5 speed case is almost straight as it passes the speedo cable. 76 has a noticeable bend.

-

How are the bushings in the shifter? If they're bad they'll let the lever move too far and it might bind up before it moves far enough. There's a round plastic one on the bottom and two at the fulcrum pin.

-

You didn't fabricate some sort of flywheel locking device in order to torque the bolts did you and forget to remove it? You said "lock flywheel". Leave something in the oil pan? Get the oil pickup tube jammed in the crankshaft? You're looking where no work has been done. 1) Drop oil pan 2) Impact gun + thread on pulley puller to remove crank pulley bolt + washer 3) Remove front timing cover (anything else while the cover was off?) 4) Replace crank snout seal (seal installation screwed up somehow?) 5) Bolt front timing cover back in place with new gaskets (something got jammed?) 6) Bolt in AZC oil pan with new gasket (has it been removed and things checked yet?) 7) Lock flywheel and torque crank pulley bolt + washer back to ~100 ft-lb with loctite blue (flywheel locking method?) You have an odd situation...

-

Just curious, but what exactly is getting pressure when you press the axle in to the differential? Does the internal clip let go and the axle moves inward? Or does the clip hold in that direction and the pressure is on the inner spline? Inner bearing races, axle dust shield? I don't have a good picture in my head of what's connected to what, or what the dimensions are.

-

Does the lever move up in to the spot for 5th but nothing happens? Or does the lever just not go to that spot? Are you sure it's really a 5 speed? People switch knobs often.

-

Undo the stuff you did between works and doesn't work. Damper pulley, oil pan, whatever else. That's what I'd do. Damper still looks most likely since it's on the crankshaft.

-

Could also be that somehow you've jammed the damper up against the timing cover.

-

If I'm reading right, the actions above are the last significant actions between when the crankshaft would turn and now, when it doesn't. Seems like the damper (I think you're calling it the crank pulley) reinstallation is the most likely cause. Maybe you jammed the woodruff key past its keyway in to whatever is behind it (I don't know what's behind it, I think more keys and keyways). 100 ft-lbs can do some jamming. Might try loosening the damper bolt or just removing the damper, then using the propeller shaft to rotate the engine. Put the car in gear and roll it. Inspect the woodruff key slots for damage first, might have to be fixed anyway.

-

A too-long bolt in the thermostat housing will pin the timing chain guide to the chain and sprocket. The threaded hole is open on the back. Not uncommon. Don't forget the belted accessories also. Alternator, AC compressor, water pump and fan.

-

You said that the clutch works. Not sure how you tested it, but if you have someone press the pedal while you try to turn the engine that should tell you if the transmission input shaft is bound up. Unless the input shaft is jammed inside the crankshaft pilot bearing, disengaging the clutch should leave you with the engine only. If it turns with the clutch pedal down, bit not with it up, then the input shaft is stopping the movement. The transmission output shaft should turn while in gear also, if the clutch is disengaged, since it's the engine and the transmission that are being engaged and disengaged. Except for the pilot bushing. In short, a working clutch system should separate the potential problem areas. Edited - spelling

-

Can't remember exactly where I saw it, two places I think, but it was very recently: check that you didn't use an overlong bolt to install the slave cylinder. Apparently it's possible to jam the bolt end in to the pressure plate cover that way.

-

Actually he said the post at the top of the picture, the "A" post, was disconnected. That would explain the lack of charging. He may have fixed that but doesn't realize that he probably blew a fusible link when the wire touched body metal as it was dangling around, shorting the battery. Wiring issues can get out of control.

-

Unable to bleed front brakes

NewZed replied to MikerZ's topic in Brakes, Wheels, Suspension and Chassis

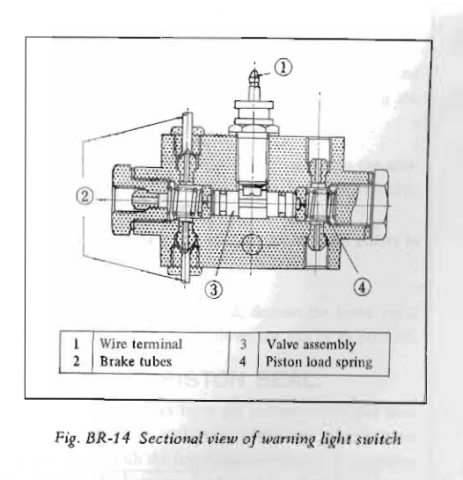

Here's a picture of the older switch. I really don't know how the older ones work, I've just seen that they need to be reset if they get tripped. Maybe they have a tendency to get stuck? My 76 had the switch and it fixed itself as soon as I fixed the problem (calipers on wrong sides). The OP never said what year car he's working with. -

Unable to bleed front brakes

NewZed replied to MikerZ's topic in Brakes, Wheels, Suspension and Chassis

Nissan changed the switch design sometime in the first few years of the 240Z. You're showing the newer design. -

Unable to bleed front brakes

NewZed replied to MikerZ's topic in Brakes, Wheels, Suspension and Chassis

MC's have been known to destroy their seals when they see a new part of the bore. The booster just amplifies the force from your leg, Brake fluid is denser than air. There must be some pedal pressure, there's a spring and you're also pushing on the rear brake system. -

I got the impression that the TPS should have a value at closed throttle and that MS is then calibrated to that value. In other words, you would tell MS that "6" is closed, and that whatever value the TPS puts out at wide open is 100%. Most sensors always put out a signal and the control system is calibrated to what you want those values to mean.

-

One cable or two? Maybe you're putting them on the wrong terminals. You're not really using that meter are you? You said you "put the meter on the ignition coil" but didn't report any numbers. You can check for a short to ground before you connect the battery. No need to look for sparks.

-

Yet another rotor sizing question...

NewZed replied to Blob1620's topic in Brakes, Wheels, Suspension and Chassis

Hybridz member Nigel has done some nice work in the past. Wrote up the 71C transmission swap for the S30. Seems to know his stuff and he's dug in to the situation you're currently in. Worth a read for sure, maybe the next group. http://forums.hybridz.org/topic/113199-yet-another-rear-drum-to-disk-conversion-option/ -

So what are you seeing that's different between the two? Sounds like you think it's a clocking problem, since you mentioned drilling holes. There's a whole calibration procedure described in the Megamanual.

-

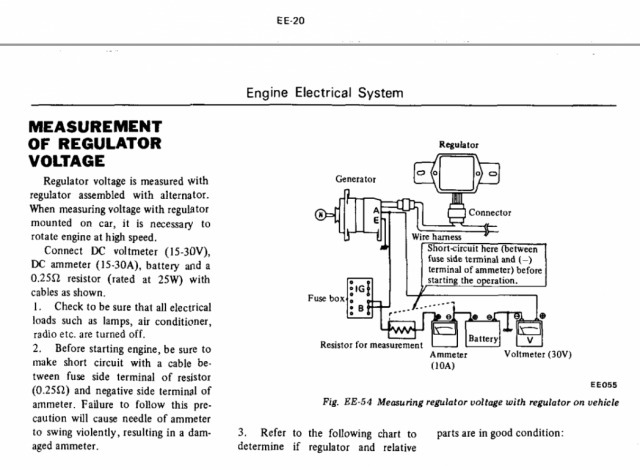

Missed the part about "you were tempted". Thought you already did it. There's a whole long procedure for testing the external regulator in the Engine Electrical chapter. But, it sounds like your L wire has just lost it's connection. I think that is described in FSM also. The simplest of checks is to just turn on the key and check for battery voltage at the T plug on the alternator. When working on electrical stuff, your first action is always to check that power is getting to where it's supposed to be getting. Once you actually use a meter for more than 5 minutes and either confirm power, or confirm no power, you'll never post again about "maybe I should check for power". It will be incomprehensible to not use the meter first. Some people carry meters in their car.

- 5 replies

-

- 280z

- alternator

-

(and 4 more)

Tagged with:

-

S30 OEM brake line diameters?

NewZed replied to superduner's topic in Brakes, Wheels, Suspension and Chassis

I think that the lines were all essentially the same over the years. Probably the same for all Datsun/Nissan/Infiniti platforms. It's the actuating cylinder sizes that affect pedal effort. The metal lines just allow fluid movement so size doesn't matter. The booster has to fit the mounting studs and clear other parts. The master cylinder should be matched to whatever it's pushing on. An all disc setup would need a different MC than discs and drums to get a good balance of travel, effort, and stopping power. -

On 1 - you didn't say anything about rewiring to use an internally regulated alternator. It's not just a bolt-in and go swap. On 2 - have you read page BE-42? At least that's the page in the 1976 FSM. The 1975 version online doesn't seem to have a BE chapter. No signs of any meter measurements either. Take the gauge out and measure at the plug if you can't find the source wire.

- 5 replies

-

- 280z

- alternator

-

(and 4 more)

Tagged with:

-

custom ring and pinion questions for sti R180 torsen LSD

NewZed replied to Ivemadeahugemistake's topic in Drivetrain

Your thread is interesting, but probably not for your original reason. To those who question how an R&P can be cheaper than a set of tires - ivemade is in the region of the world that makes most of the world's stuff.. He just happens to be in the R&P region instead of the tire region. To ivemade - the desirable R&P ratio is determined by the transmission ratios and the tire size. Most cars come in about 12:1 on first gear x rear ratio (for example 3.062 x 3.9 for a 280ZX), and use about a 24 - 25" tire. Many early transmissions had very low first gear ratios, like 3.592 (with the 3.36 rear gear - 12.07) for the early 240Z, but that changed over time to higher first gears, and lower rear gears. So you need to do the math from first gear to tire size to decide what R&P ratio you want. It's interesting outside of your goal, because you know somebody that can make custom ring and pinion gear sets. The ring gear size is not changed when the ratios are modified, it's the number of teeth, with the ring gear size kept the same, to fit the housing and differential carrier. So if your guy really knows what he'd doing, all you need to do is give him a ratio and a ring gear size and he should be able to tell you what he can do, within a certain range, like 27:1, or similar. As I understand things... p.s. my use of terminology could be off.