NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

'78 280z 5 speed transmission rebuilt - still rattles

NewZed replied to alex44's topic in S30 Series - 240z, 260z, 280z

You can find quite a bit around the various Datsun forums about the noise from the transmission when in neutral with the clutch engaged. Might be that your 4th gear grind just made you hyper-aware. I had three different 5 speeds in my car at various times and they all had the noise that went awya when you pressed the clutch pedal. I have a memory of @JMortensen telling a story about a new rebuild having the noise. I found one. -

'78 280z 5 speed transmission rebuilt - still rattles

NewZed replied to alex44's topic in S30 Series - 240z, 260z, 280z

Get a list of all of the bearings that they replaced. The adapter plate bearings are tough to do, they might have skipped those. Any notes on how far down they took it would help too. Since you told them to only replace what they thought was worn they might not have gone very far. More details on what happened after you forced it in to 4th might help. Did you drive it afterward? How did it get to the shop? Did the problem go away? -

Can't remember but I think that it might actually be in Monroe's Rebuild book. But here is a writeup that a past member put together. The towers are bored for the cam after they are installed. When they are removed any mismatch on reassembly can cause cam binding. I've never done it myself I just remember reading about it. He doesn't mention the tapping, I must have seen that somewhere else. Basically, if rotation gets tight a couple of light taps on a tower or two can loosen it up. The goal is to get everything torqued and have a cam that rotates freely.

-

Somebody probably used the torque values in Monroe's Rebuild book. Apparently there's a typo in the book, the value is too high. Make sure you do the tap-and-rotate alignment when reassembling. Nissan considers the cam towers as non-removable.

-

76 Alternator Upgrade To Maxima Alternator 90 Amps

NewZed replied to Datsunjoe76's topic in Ignition and Electrical

Here's another wiring scheme but I think that it causes the brake warning light to stop working. Or stay on. Can't remember. http://www.zcarcreations.com/howto/voltreg.htm p.s. if it's quiet when you're working on it you can hear the relay click and see a spark at the terminal when you reconnect the battery. That tells you that you still have a problem. -

76 Alternator Upgrade To Maxima Alternator 90 Amps

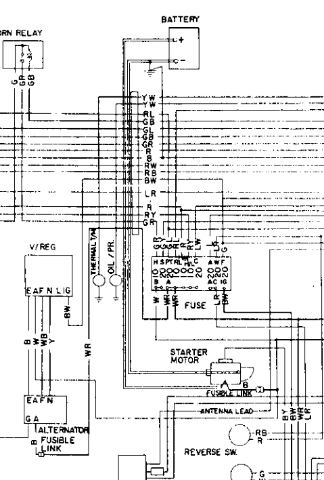

NewZed replied to Datsunjoe76's topic in Ignition and Electrical

I had the same problem. My memory is vague but I think that I found that you could just disconnect the relay and the battery drain would stop. But then the brake light in the dash does not work, for the parking brake or the pressure differential switch. The brake light even acts as an "engine not running" light. It needs power only when the engine is running, to turn the light off. Anyway, I ended up cutting the power wire to the relay, I think it's the yellow one, and tapping in to the fuel pump power line, which is next to the passenger seat. That restored the system to where it only had power when the engine was running. That is the key. The relay needs power when the engine is running only. In the meantime I think that you can just unplug it. -

Get the one for your year of car. I have found that the zstore AFM's run rich though. That could be a problem in CA. The old EFI engines take some work to get running right. It probably won't be just a bolt on and go project. It's possible that you don't really need a new AFM unless you don't have one at all. Have you done the electrical tests on it? Good luck.

-

76 Alternator Upgrade To Maxima Alternator 90 Amps

NewZed replied to Datsunjoe76's topic in Ignition and Electrical

You might be on the right track. The relay is under the passenger seat. What wiring scheme did you use to get rid of the external voltage regulator? There are at least two common ones. -

Is it an R180 or an R200?

-

Most of us call it an air flow meter - AFM. https://www.thezstore.com/page/TZS/PROD/11-3040 https://zcarsource.com/fuel-systems/fuel-injection-components/air-flow-meter-mass-sensor/

-

If you have a meter or test light you can also check for power at that terminal when the key is turned to Start. That's what the ignition switch does, sends power there.

-

The most common reason for just a click is dirty battery terminals. Make sure that they are clean and tight, at both ends of the cable. Watch out for those clamp-on terminals they go bad often. If you apply battery power to the starter solenoid terminal the starter should turn the engine. Make sure the car is in neutral. You can do this with the key off, using a piece of wire from either the battery terminal or right at the starter motor. Even a screwdriver works if you know what you're poking at. That will tell you if it's a switch problem or something at the starter or battery. BBB Industries has a good diagnosis video that might be worth watching. https://www.rockauto.com/en/moreinfo.php?pk=536171&cc=1209394&pt=4152&jsn=440

-

Diff crossmember structural rigidity questions

NewZed replied to Zetsaz's topic in Brakes, Wheels, Suspension and Chassis

Pretty pretty pretty sure that @JMortensen looked at that in the past. -

Dished pistons never have any "real" "quench". The turbo engines aren't quench chambers. "Quench" or "squish" is a word that is usually undefined and unmeasurable. Usually determined by eyeball. There's a theory, combustion gases squirting and swirling around, piston tops being cooled, etc., but I don't think that you'll find anything anywhere where anyone has shown that they compared "quench" to non-quench in an L engine and saw an effect. Most of the discussions center around the old "engineers did it it must mean something". No offense to anyone intended here. If someone has data that would be cool. While you're researching, look for stuff on the exhaust port liners and turbos.

-

Also hilarious when somebody joins a forum for the sole purpose of criticizing another person's post. Even funnier when they don't offer any sources or even a clue about who they are. Just another voice in the wind. Hear my opinion.

-

Engine Blow-By. Catch Can hose routing

NewZed replied to 5 Star Rising's topic in S30 Series - 240z, 260z, 280z

You're not going to blow a head gasket from excess crankcase pressure. Maybe a valve cover or oil pan gasket. The milky stuff would be because combustion gases contain water and you had blocked the path for combustion blowby to escape. Don't tear your engine down for the wrong reasons. -

Engine Blow-By. Catch Can hose routing

NewZed replied to 5 Star Rising's topic in S30 Series - 240z, 260z, 280z

You are correct, you blocked off the crankcase vents and are allowing pressure to build in the crankcase. You could disconnect the hose to the side of the block and leave it open at the catch can. That would allow venting and the catch can might actually catch vapors before they exit in to the engine bay. You would want to block the port in the side of the block if you do that, otherwise you'll have oil vapors leaking our down there. -

New 280zx Alternator Swap not charging 240Z.

NewZed replied to 5 Star Rising's topic in Ignition and Electrical

The B+ terminal where you would be measuring the 16 volts should be connected to the battery positive post through the lug at the starter. There is a fusible link in the circuit. Use your meter and check the circuit. Follow the wire from the alternator to the battery post. Check the fusible link. Looks like Nissan ran the circuit through the fuse box on the way to the starter. The ammeter is on a parallel circuit, called a shunt, that would not control current to the battery. -

What brand of piston? Add connecting rod to the possible cause list. If the problem stays with #1. That's probably what you meant by hole. Interesting problem.

-

-

Some 280ZX's come with an R180. It's the smaller weaker diff. Might be the one you had and that's why it disintegrated. The R200's are pretty tough. But if you really want something stronger, the answer is in the forum you posted in. https://forums.hybridz.org/topic/128217-ford-super-88-irs-swap-thread-rear-brakes-too/

-

This is more important than setting the TPS, it will never really run right if the spring tension in the AFM is not right. See if you can find the glue blob marks and rotate the wheel back so the glue blobs match. No idea why you decided to loosen that screw, you really don't want to mess with it. As far as the TPS, it depends on what type it is. Is it a switch or sensor? If you got the original with the car put it back on the 240SX TB does not add anything to performance. Here's a link to FSM's. https://www.classiczcars.com/files/category/9-factory-service-manuals/

-

You don't even need to push the clutch in. None of those modifications should affect the ability to start it. You'll probably need a multimeter and/or test light to get it working though. The old electrical connections and relays and various other parts tend to get crusty. You can get factory service manuals at various other web sites around the internet. You'll need one.

-

Oops. I missed that. But, ironically, it makes the numbers even more suspect without the verification. No offense to him, but he is selling parts. Let's see the dyno sheets or at least a description of how they were tested. Somebody with an LS swap did some burnouts? I don't think he's getting 400 ft-lbs from an L26 or L28, even with a turbo. You can find a lot of posts from the past making fun of the 800 HP claims for various axle options. Seemed picked from thin air.

-

Curious - how do you know this?