NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

need help QUICK! difference between turbo and non turbo slave cylinder

NewZed replied to supernova_6969's topic in Drivetrain

- 7 replies

-

- clutch

- slave cylinder

-

(and 1 more)

Tagged with:

-

You have to pick one. The only way to fit your words is that the clutch is in a state of constant slippage. Is this a new problem on a system that was working fine? Or is it a bunch of new parts that aren't working right?

-

Common problem. The site owner just hasn't clarified that you have to be a donating member to post a For Sale ad. Besides that you're breaking the Rules. Post a price. http://forums.hybridz.org/topic/113791-classifieds-rules/

-

Since you can read a diagram and know the wiring the best thing you could do now is to sit down and draw up a new diagram for all of the things that you want to use. The answers to your questions will fall out of figuring out where to draw the lines.

-

I suggest that you stop thinking in terms of Megasquirt and computers and switches and focus on how electronic engine management systems work. Understand what the engine needs then use your Playstation skills to give it what it needs. Read the EFEC, and the Engine Electrical, chapters of the FSM and you'll be way ahead of where you are now. You're approaching your project from the wrong side. Here's another good starter book, written by the guys that run DIYAutotune. It covers most of what you're asking about. https://www.diyautotune.com/product/performance-fuel-injection-systems-hp-books/ http://www.amazon.com/Performance-Fuel-Injection-Systems-HP1557/dp/1557885575

-

You're way behind where you need to be. Does the car run and drive now? Because it will be down for a long time if you start tearing in to it. Is it an automatic transmission car or are you talking about controlling the various switches on a manual transmission car? Where does Rasperry PI come in to the picture? Any old computer will work for tuning. Most people use the word "launch" to mean leaving the line in drag-racing. You mean "start". And it's not the soldering that's important it's making the right connections. If you're asking about a kill switch and a start button, Megasquirt is going to be a nightmare for you. https://www.raspberrypi.org/blog/raspberry-pi-compute-module-new-product/

-

Avoid thought processes that lead to random collections of words. Good that you mentioned that you talked to someone at DIY, but have you looked anywhere else? You know how to solder and read a diagram. What else? Seriously, you're not showing what your level of knowledge is. Do you know how the stock system works? Understanding the stock system, by reading the FSM will help you out a lot. The same basic principles apply. Have you looked through the FAQ's? Good reading there also. http://forums.hybridz.org/forum/93-megasquirt/

-

This is one of those "if you have to ask" questions. If you have to ask, then you'll probably run into problems. In principle, the E88 head, complete with cam, rockers, etc., should bolt right on easily, giving you a typical L28 engine but with smaller valves. Basically a flow-choked L28. Apparently there are several E88 varieties though. Better learn more about what you really have. http://www.ozdat.com/ozdatonline/enginedesign/ http://www.zhome.com/ZCMnL/tech/head.htm

-

Are you sure it's fuel? Not oil? Or oil and fuel? If you have good rings, the cylinder should be getting the same amount of fuel as the others, it's blended at the carbs.. A wet plug could either be a misfire or it's not just fuel, it's oil and fuel, and the oil is causing some misfires. Fuel will dry off pretty quickly, oil won't.

-

I don't think that those plastic pintle caps in the stock manifold is a very good fit. I'd use a thin flat rubber washer myself. Maybe even remove the caps. I have a different type of 14mm injector, with no pintle cap and it barely reaches the other side, with an o-ring seal. Yours are stopped by that ledge on the pintle cap. Put an o-ring on and the spray pattern might impinge on the manifold hole. Better test fit and look. My thought process overall was that there's fuel pressure pressing down plus intake manifold vacuum. NA engine. Turbo engine's have more issues.

-

Never heard of them. Google says they're based in South Africa. But you're in Miami. Looks interesting. Good luck. http://www.gotech.co.za/

-

If you're using the CAS you were working on in your other thread, the ECCS controls spark timing. So when you set the CAS and distributor up according to the FSM, rotor-phasing should be correct. The only way you could change your phasing would be to rotate the CAS disc, which is not possible without modification. You have a stock ECCS system right? Nissan computer, CAS, etc.? I'd do what the factory says to do. Sorry to keep jumping in to your thread. I'll butt out if you want to hear from the turbo guys.

-

The FSM's are usually right. I go there before reading what random people on the internet that I don't know have to say. That is an ironic recommendation, of course. I'd crank it up, were it mine. Have a timing light handy. www.nicoclub.com/FSM/280z/1983/1983%20280zx%20FSM/

-

-

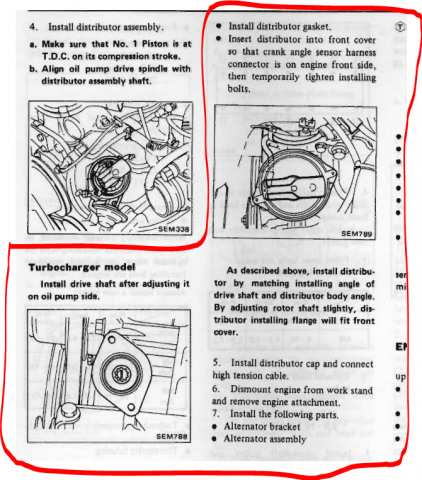

Did you look at the FSM online? Engine Mechanical - Assembly - Turbocharger model...

-

Man, you should have said in Post #3 instead of your snarky reply. You screwed up.

-

This is where writing skills come in to play. The phrase "instead of" would have helped. "S14 instead of S13". Then "if I use S14 calipers would the Z31 rotors work?" You wrote an unclear question then insulted somebody who gave good advice. Good luck. The internet is not really free.

-

Bench Bleeding 15/16 280zx master cylinder

NewZed replied to zgeezer's topic in Brakes, Wheels, Suspension and Chassis

I read your description as one cylinder (the MC is two cylinders stacked - in series basically) doesn't drain back and one does. With an open bleed screw you're not really generating any pressure. The back cylinder pressurizes the front cylinder. Most of the FSM's have a really good drawing of the MC internals. Some study there might give you a clue. But... Seems like you might be focused on an observation of something that doesn't really matter, along with the clicks at full stroke, which the MC will never see. Is there an operational problem? -

Read the MM web page. You could have answered your question in the time it took you to write and edit your post.

-

Where to source counter shaft bearing for the 83 280ZX FS5W71B

NewZed replied to wigenOut-S30's topic in Drivetrain

Where's the pictures? Which end, under the front cover or at the adapter plate? Curious, I've never heard of anybody blowing up that bearing. Usually it's the one in the adapter plate that goes. And I'm not sure which of the two go, the main or the counter., And how did it blow? Ball bearings everywhere? Was there other damage? Interesting problem, you should add more details. -

Why inch your way down from what is damaging your engine? Crank it way down to where it's gone and inch your way back up. If the head has been skimmed, you could have pretty high CR. But, the fact that it "started just recently" would indicate that the setup can work without detonation. More detail than "just recently" might offer clues. How long did it run well, what changes have you made recently, etc. Ideally, you would just dump as much information as you can in to a thread like this, in the first post. People will get bored and go away if it takes hours to just to get to the simple stuff. It took 10 hours just to find out what your timing was set to, and now 8 hours later, it's not even there, it's at 10. Good luck.

-

It's worth a lot to anyone that's converted their 240Z to an EFI system. The 240Z tank ports are too small for the fuel flow of an EFI pump.

-

How fast does it advance from idle? Put the light on it and take a couple of simple measurements. Maybe you have a broken advance spring. Also, for troubleshooting purposes drop the timing to 5 degrees. Don't hold on to the number you want and try to make it work, Figure out what the real problem is first. 15 is already higher than spec. You have more advance than spec,, and a higher CR than spec. on an engine that likes to detonate. And, when did it start doing this? Are you familiar with the engine or is it new to you? Could be you're spinning your wheels on a bad tank of gas. Just because the pump says 97 doesn't mean it's 97. When you say you tried race gas, do you mean you drained the tank and refilled with "race gas" or just put a few gallons in? And, as I understand things, in certain parts of the country "race gas" means methanol. And they mix it with Mountain Dew and drink it, then go to the hospital. What's the octane rating of your race gas?

-

How about a number? Are you running zero advance? Or is initial set to zero?

-

It's not normally done. There's only a tiny stub at the top of modern injectors after you cut the plastic away. Not much to fit a hose and hose clamp on to. And it's not a barb, it's just a round tube shape. Looks like these guys are doing that modification and selling them as replacements. But it's kind of a hack job. The injector companies put those barbs on there for good reason. With no flare and no barbs the hose could easily pop off. https://www.fiveomotorsport.com/fuel-injectors/nissan/280zx/ pallnet sells rails for the Z engines that will take o-ring injectors. http://forums.hybridz.org/topic/99098-pallnet-fuel-rails/page-15