Leaderboard

Popular Content

Showing content with the highest reputation since 05/08/23 in Posts

-

Don't tell my wife Like I tell other people. some like to fish, some like to bowl, I like to make.6 points

-

He's saying although we are launching a DOHC head in 2024 we readily admit it will be pale in comparison the mighty KN20 from Datsunworks. At least that's what I'm hearing.4 points

-

4 points

-

**UPDATE Went to court yesterday and basically played dumb. Told the judge that "I went to the state ref and he told me since the car is so old that he couldn't do anything to certify it. So how do I go about taking car of this ticket. The vehicle is a pre smog vehicle so I've never had to SMOG it" The judge said "Ok so what Im going to do here is dismiss the case cuz it seems like your car doesn't qualify for an inspection. Sorry about the inconvenience Mr. Soto" I tried to play it cool but I was so happy. After reading all the horror stories from other people about having to revert to stock and all that I was lucky I guess Hope this thread helps someone going through something similar4 points

-

Greetings Everyone, Due to the increase in spammers HybridZ, registration has changed from being automatic to manual. That means one of the Admins will need to approve any new registrants. If you ask or tell someone about HybridZ (please do) let them know registration isn't automatic anymore. We'll do our best to stay on top of any additions and hopefully you all will see a lot less spam. Thanks, The HybridZ moderation team4 points

-

3 points

-

Unfortunately, it is too late. Maybe for round 6 in a couple of years Got the shirts in and will start breaking things down and shipping things out next week. This week is busy with work travel, so appreciate your patience while I get a few out each day on my lunch breaks.3 points

-

They received all of the shirts without backorders and are starting on printing this afternoon!3 points

-

I really wish things would swing back towards the forums. I can't tell you how many times I know the answer to or could add to a post on FB but I don't since it really has no longevity. I always felt like I was adding to the overall knowledge base when I posted here. I can go on and on but I really hate it.3 points

-

First start up since starting the restoration. Kind of shocked she started right up on the first go. Was expecting something on the MegaJolt to need fixing, but it worked great. Went with Magnacor wires, but they made a mistake and did not fit them up with the right coil boots. Being remade and shipped, so I am using 05’ ford explorer NGK wires for now. Went with a “7” heat NGK plug on account of the 10:1 CR. It’s raining this weekend, but just need to dial-in some crude alignment and she will be road worthy IMG_2339.mov3 points

-

Just wanted to say again a HUGE "Thank You" to @cockerstar for doing this (a FIFTH time)!!!! Really appreciate all his time and effort to make this happen. You da' man, Ryan!!! 👍👍3 points

-

3 points

-

Update : I had been fighting an erratic wideband on the rear collector -cylinders 4-6. Well it turns out I still had a leak at the collector which is before the O2 sensors - dammit . This is a Z story header and collector . The collector pipe was modified for my exhaust and I thought I had the flange true , but it still leaked . This time around I eliminated the gasket all together and used Red Loctite only . At the same time I had a new O2 sensor installed since I was that deep into it . I DID see evidence of a leak but changed the sensor anyways . FIXED! This change helped so much with the tune and you could hear it ! I was able to get the banks to harmonize much better with AFR’s and sound . This helped to mitigate the drone I was getting at low rpm cruise . I thought this would also fix an issue I’ve seen on every intake I’ve used where the AFR’s between the two O2 sensors would be different during high vacuum running - light cruise . Megasquirt didn’t seem to be able to compensate in those scenarios though I had two separate O2 sensors dividing the banks . I ended up going into the injector trims and adding fuel to 1-3 since they ran really lean under high vacuum . Maybe they suck all the air out of the plenum before it reaches the last 3 cylinders . I added almost 20% to 1-3 . At this point the AFR’s evened up and you could feel and hear the difference . This is probably the best I’ve had my L running . Happy guy right now2 points

-

It's not the votage drop that matters it's what the voltage drop indicates. No spark will be created if the current through the coil is not stopped. You could also disconnect the coil negative at the coil and check the wire for continuity to ground, key off. Disconnect the wire, put one meter probe on the end and the other probe on a good bare piece of metal or the engine block. You should get OL or infinite/huge ohms on your meter.2 points

-

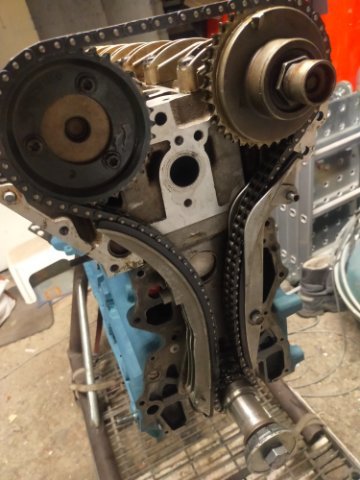

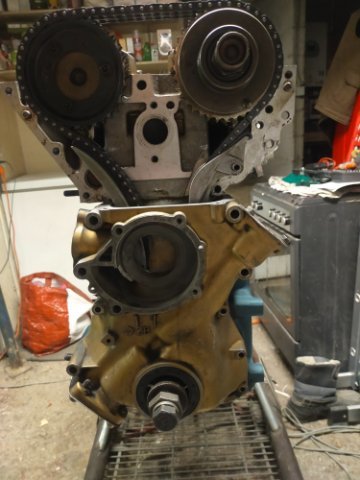

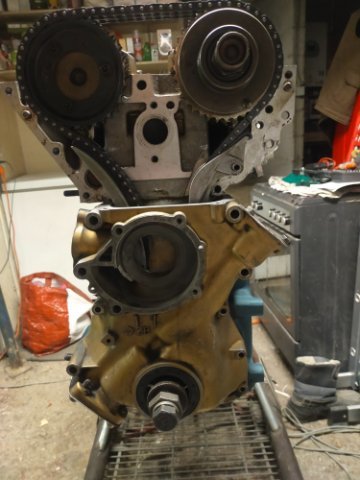

well yes , stock guides , just to make lower axes in the block, and the stock cover is modified to make some space, electric water pump ( davis Craig ) , and tensioner on the right side, in place of the water inlet ( spring and lock without oil pressure ) no need for oil pump drive or distributor for i put dry sump pump system and megasquirt ignition and injection EFI with yamaha bike itb's So simple and cheap , just a little of brain storming ! oh ! and a little joke for the head cover !! Lol !2 points

-

There is no swap hardware to put the Z transmission behind a V8. It wouldn't handle the torque anyway. The 260Z engine is about 158 cubic inches, compared to 350 for a SBC. The old Z transmission bearings are typically ready to fall apart besides that, not uncommon even with the stock engines. It would probably last about one pull. I haven't done it myself, but I wouldn't even try it just based on what I've learned.2 points

-

You have packed a lot into your intro. There's some good advice below to consider in the posts to your question. But I have to ask you what is it about the 280 you love? I don't mean that coyly or as some flippant remark. What is it you really like? I'll give you why I like the Zs. I grew up around them when they were new, my uncle was a general manager of a Datsun dealership so we got to try out the new cars. We raced with my uncle at autocross and hillclimbs (I was a kid so I just went along). Back then the Z cars were fast and sounded awesome (I have the hearing loss to prove it), and were amazing at cutting through the corners both stock and modified. Our local racing club had about 10 people driving stock to all-out racing versions. 50 years pass and a lot of that coolness has mostly worn off except for the look of a lowered S30 with an airdam and rear spoiler. I have to admit the sound of a modified Z makes me happy when I hear it. But this site exists to help people get the most out of them. And the reality of that is as cool as the L28 engine is you're looking at spending a lot of money and you'll have an engine that makes 200 to 250 HP. Sure you can get more but then all the other parts that connect to that engine are starting to get pushed past their limits given the age. While I don't disagree with any of the posts below you should still read about a lot of the mods and why they were done. You'll find that in many cases they were driven by it costing too much, parts NLA, etcetera. A bit of advice from me. Never by an engine, transmission, or rear end unless you plan to use it within a few months. Even if you plan to use it that's not the same as ready to bolt in. If you want a street car with a certain coolness and triple Weber carbs, then build it. But when you spend 10K on an engine and find it's somewhat finicky to drive but cool all the same. But for less, you could have 350 HP V6 in the DI Chevy LV3. It won't sound the same as the L-motor but it's lighter, a lot newer, and will get excellent mileage, It will start anywhere if it's hot or cold by the sea or at altitude. This site has a ton of info on how to do the same for the suspension and how to get a cheaper rear diff, especially if you want an LSD. I could write a lot more but this is probably too long as it is. Welcome to Z ownership. Cary2 points

-

Yes, with the carbs you can get rid of the ECU and EFI parts. The complete EFI harness can be removed. The guys that know on the site (from the past) say that the exhaust system is restrictive and opening it up helps a lot (see John C posts from the past) , and that if you decide to use a performance cam go big (see JMortensen posts from the past). The typical "Stage" 1 or 2 cams don't add much, apparently. So, the simple and effective way to add some power is with a better exhaust system and a big cam. Cams are more expensive than they seem because you need to buy lash pads and rocker arms along with the cam. The collection of parts costs can add up. But it's a pretty simple operation to get it done. Many people like the lighter flywheel. It takes more finesse on the clutch pedal but they say it's worth it. Fidanza is a good choice. For street driving an LSD doesn't add much. You might wait on it and see if you have traction problems. There is a ton on the site from the old-timers, around the 2000 to 2015 time range. Things have slowed a lot on the site as people have moved on. But their contributions are still here. Many of the guys were racers and/or engineers/mechanics/machinists and spent a lot of time and money on their projects. Today's car hobbyists really only know turbos and EFI since that's what they were raised on. Good luck.2 points

-

Even if 100 people commited to purchase, its still tiny small numbers vs an OEM production. Its got to be done out of passion and at least not to lose money. This is why this is such a huge acomplisment for someone like Derek, We are fortunate the passion runs deep. I cant imagine the hours of "un-billed" time2 points

-

Life has been kicking my ass lately! Between my job changing significantly, being super sick, and some significant medical issues with my daughter I haven’t made the progress on shipping orders that I have wanted to. Post here if you’re really itching to get yours and I’ll move it to the top of my list. Otherwise I’m moving along as ordered. I’d like to get these wrapped up so I can transfer the remaining funds over to Dan.2 points

-

We’re going on track this Sunday at Willow springs Will set-up the car tomorrow at a friends shop since they have a flat-level garage floor (which I do not). Also in the middle of adapting the front brakes to 280zx rotor and caliper per EP spec-line. Caliper mounting on the strut assembly will require some welding and drilling, so it will have to wait till after this weekend. Greg Ira was nice enough to ship me some race pads he has that fit the OEM calipers.2 points

-

2 points

-

Hi everyone! I have the shirts and should be able to start getting some out today. I was primarily working from home at least 80% of the time, but my job just got pushed to 60-80% travel so I haven't had breaks at home like I used to.2 points

-

Well, after more testing, it seems to be a user error. Was able to drive for a good hour today without and bucking/shudders. I think it's a combination of a new clutch and upgraded transmission/rear end that I have to get used to. The car seems to like higher rpms when starting from a stop, and a different clutch engagement that what it was before. Car is much more fun with the new parts. Not a fast car, but a fun one.2 points

-

No, you just pull the bearings off of the front of their shafts. The countershaft bearing is pretty tight to the gear and takes some trickery. The mainshaft bearing needs a puller with long arms. You can push the rods back to get more room. The transmission will have multiple gears engaged but it won't matter. When you reinstall the front case put it in a single gear (one rod moved) to avoid locking up the transmission by accident. Here's a decent video about the countershaft bearing, different tranmsision but same concepts. He did the same thing I did, clamping a two jaw puller in to the gap, otherwise the jaws pop off. The mainshaft is a more normal operation but the length of the shaft has to be managed. It takes some work. If you have friends that have pulled bearings or gears it might be worhtwhile to get some more ideas and tools on-hand. Notice the odd combination. Go to 4:00 if it doesn't start there.2 points

-

4th gear doesn't use the countershaft, it's direct drive. That's a good clue. Sounds more like the countershaft bearing. Looks like you'll need to split the cases, so you might as well do the mainshaft/input shaft bearing also. It's not a super-finesse job. Just needs some ingenuity. It's fun. Part of Z ownership. Here's a good illustration of the parts you'll be looking at. I'm sure that there are "how-to" videos out there somewhere. You can get a factory service manual on the internet that shows how to take it apart. Good luck. https://www.zhome.com/ZCMnL/tech/240SX5spd/Transmission2.htm2 points

-

"Grinding" is not very specific. Can you add details? Have you driven it? Is it the same in every gear? 71B's are known for destroying the adapter plate bearings. Did you find any metal on the drain plug magnet? If you've been driving it you might drain the fluid and see how it looks. Might also be worthwhile to lift the car and get underneath with the engine running to see if you can locate the noise. Replacing the main and countershaft bearings is not very difficult. You only have to split the cases and pull the bearings off of the ends of the shafts. The adapter plate bearings are more difficult.2 points

-

Order is with the screen printer and will keep you guys posted when I get an ETA on delivery.2 points

-

Finally got this thing tuned right, kept fighting an issue where the car would break up on quick throttle changes and in boost. Engine had NGK b6es-11 plugs, I went to a NGK bpr7es and all my problems disappeared. Engine is leaking oil pretty bad though from what looks like where the timing cover and cylinder head meet, l am genuinely amazed at how much oil can come out of there. The stock head gasket was torn there, and I RTVed it up a lot after the fact. Maybe my PCV valve is faulty and pressurizing that area under boost? Once I get this oil leak handled Ill take it to the dyno.2 points

-

2 points

-

@calZ, I spoke with John yesterday and I'm going to do another round. 36 item minimum from my print shop, but I think we can hit that!2 points

-

I am still around, I don't check regularly. I still have my Z. I joined here when I was 15, I am about to turn 38.2 points

-

Hi HybridZ universe! Been taking a break from the car for a bit, but starting to get more motivated here. Let's do our quick catch up first. ORP was an interesting event. We had positives, but the issue that wrecked the car in July surfaced it's head again. Turns out the ABS was overpowering the master cylinder seals on the front circuit and causing massive pressure losses. I had more pronounced but less consequential failure out there, but had good data to show what was wrong. I got my hands on some Tilton Type 79 master cylinders, developed specifically for the Audi LeMans teams who were seeing a similar failure in their master cylinders. I also had to upgrade the pedal box as these are bearing mount master cylinders. The plan was to run the car again at PIR, but that event ended up getting canceled, and so the car has sat since September. Slowly getting poked at, and trying to figure out where I wanted things to go. I made some aero mods to the fenders, and have been slowly cleaning up the firewall and some other areas. The big change I'm in the middle of here is with my ECU. I'm ditching the megasquirt and going Haltech. The LS never really ran right on the megasquirt, and when I started seeing some odd stuff starting it up for the first time this year, that was all the impetus I needed to ditch that. It'll be for sale shortly, expect to see it soon. Hoping to get to an event this year with the car, but really not sure when or where. For now, here's where we sit. I put it down on the ground for the first time since August last year.1 point

-

Nice-looking piece. Can I suggest you move your post to the Vendors' Forum? https://forums.hybridz.org/forum/27-vendors-forum/ Thank you.1 point

-

1 point

-

1 point

-

@jhm @tube80z helped me out. super simple solution. For anyone in the future, double check the size of the image (1600x1200) is what i resized to1 point

-

A friend built an endurance car (Chumpcar/Lucky Dog) and was going to use a new Nissan gasket. I talked him into gluing the windshield and was amazed at the results. The difference between this and a normal gasket was the same having a strut bar or not. This car has been used hard, ridden some large curbs, and never cracked a windshield. I'm not saying it can't happen on the street but I'll be gluing in my street car's windshield when we get to that point. Cary1 point

-

@jhm thanks John!! Yeah I fabricated the sway bar mounts over a year ago, before paint, so I’m glad to see they work as intended. They are tight! I mean… really tight 😂 zero play, and it responds immediately. Far cry from OEM in hindsight. yeah I got the set for $500 locally! I can’t afford all this race car stuff without getting it at steep used discounts. Now I need a set of wheel levelers, as my garage (aka, 1920’s cellar) is wildly uneven. I’ll get the fender and hood on, so I can take some more shots of it moving around. Really happy with the way it handles so far. I did string alignment, but I need to re-do it on a flat, level surface.1 point

-

1 point

-

All the Z iterations can look good with minimal modifications. I personally think the z32 had perfect proportions not surpassed since. So simple but so exact. For this build as all of my builds, I am sticking with stock half shafts and Spicer U-joints. Never had a fail road racing yet. Cheap and effective only if you limit the angles generated and minimal power loss. I currently plan to raise/lower the diff as required to keep them in their sweet spot. They even withstand high power drag racing if you can keep them close to straight when launching. If it looks like I will struggle with this when I final assemble the rear, I will be scrambling for some CVs.1 point

-

The factory mounts are pretty tall. I think you're going to have to remove them with any seat you choose at that height. If you want to race might need to go 1x1 square frame and screw directly into the tubes. BTW, removing the mounts is a PITA too. 487 spot welds holding those bastards in.1 point

-

Get factory workshop manual. Clean all grounds in engine compartment and the connectors for the ECU and fuel injectors. TPS, AFM, all sensors.1 point

-

Updated list and payment instructions sent to everyone 1. 7d2jz 2. MAG58 - PAID 3. MAG58 - PAID 4. Crespo79 - PAID 5. Jeffrox 6. jhm - PAID 7. onthego- - PAID 8. onthego- - PAID 9. pepper - PAID 10. pepper - PAID 11. ModernS30 12. Masonvonritchie - PAID 13. rxx2rxx2 - PAID 14. rxx2rxx2 - PAID 15. Sonethirty 16. S30TRBO - PAID 17. S30TRBO - PAID 18. Kennysgreen280zt 19. Kennysgreen280zt 20. Kennysgreen280zt 21. ElliottOhZ - PAID 22. Oki570Z - PAID 23. lowrider - PAID 24. lowrider - PAID 25. lowrider - PAID 26. jnjdragracing - PAID 27. jnjdragracing - PAID 28. OldAndyAndTheSea - PAID 29. OldAndyAndTheSea - PAID 30. JonRHD - PAID 31. JonRHD - PAID 32. 75280z 33. 75280z 34. CalZ - PAID 35. CalZ - PAID 36. LanceVance 37. LanceVance 38. Stunt 39. Stunt 40. _akuma_no_zetto_ - PAID 41. _akuma_no_zetto_ - PAID 42. 1 tuff z - PAID 43. 1 tuff z - PAID 44. Zlost - PAID 45. AydinZ71 - PAID 46. AydinZ71 - PAID 47. zredbaron 48. zredbaron 49. zredbaron 50. airbrush-ed 51. Chris Damato (FB) 52. Chris Damato (FB) 53. evildky 54. torqen2k1 - PAID 55. torqen2k1 - PAID 56. torqen2k1 - PAID 57. torqen2k1 - PAID 58. torqen2k1 - PAID 59. torqen2k1 - PAID 60. Mayolives 61. Mayolives 62. Mayolives 63. bkz72 64. Wizzurp 65. Wizzurp 66. Leon 67. Gollum 68. Gollum 69. Gollum 70. AB240z 71. AB240z 72. AB240z 73. AB240z 74. AB240z 75. AB240z 76. AB240z 77. AB240z 78. AB240z1 point

-

@NewZed if one were to avoid using a surge tank in the engine bay, I agree. You would have to solve your slosh/starvation issues at the tank. Even a momentary vapor bubble pulled into your fuel line will cause a problem with EFI, if the ~40psi doesn’t cause it to collapse. SU’s, you would be OK to a point, since the fuel dumps into an atmospheric reservoir anyways (float chamber). I am a big fan of the quart surge tank though. S30 has a ton of space up front to choose from, but it would be a struggle to fit Z31+. That’s a heck of a lot of fuel to run-through, and the shape means you will use it all before you pull Vapor into your EFI pump. To be specific, this is my experience with the L28et street Z I have (@16psi). Have not raced yet… I’m just an Engineer that comes-off as a know-it-all, and humbly accept criticism as a result. I don’t mean to be condescending, but I recognize i can be. John and Ben are real racers though cars almost running! Should be hitting the track by Feb (thanks to my California mortgage payment). good luck to the OP! PS: same problem to consider with oil starvation, but it would take significantly more lateral G’s than what it takes to suck Vapor in your tank when <1/3 tank.1 point

-

Been a while since I have posted on HZ. I ran into Jon (JHM) at Dominion yesterday. I've been coaching and instructing with a number of groups, and I've got approximately 6 regular clients I coach, and a handful who pay me periodically to review their data and footage. Some of the tools and systems I use: Harry's Lap timer (still a good and cheap product that incorporates your phone's camera) - Limited data based on your accelerometer and GPS. Down side is no sensor driven data. Traqmate - Still a great option, if you can find a working traqdash, even better - Down side is they're out of business and have been for a long time. AIM - The best and most comprehensive system I've used and I've got two in two racecars IN HOUSE - Down side is cost and complexity of the software. Tons of help, but it requires commitment to learn to use and isn't "easy" out of the box. Garmin Catalyst - The best "beginner" device going right now, but honestly, it's a fancy tablet based "Harry's lap timer" with some limited coaching functions in a tablet form. Us instructors like it because we can share data and build profiles for multiple users on the same device and then compare the data among drivers. It's still "not" cheap at about $800 to get all in with camera/wiring harness/tablet and mount. Racebox - I've used this one time only, and it seemed like a competent device. We ran it against Harry's lap timer and both read identical data. It's limited and the mount was a little finicky. For the money, I'd just use Harry's lap timer. Of course, cameras are a part of the mix, and you can spend a small fortune integrating a system to utilize the data overlays for the cameras (I'm looking at you, AIM). One of the things that Garmin does well is integrate the data and video together for easy review and uploads to SM. For those still using go-pros (I am one), Racerender is a nice way to stitch the data together with the video, if you are patient and have the desire. The instructions can be a little clunky and if importing AIM data, you need to convert the channels to CSV first. With, even the most season'ed racers, I've found many people only want a few bits of data. I log 14 channels on my 968 powered 951 racecar, and we log 8 on the 944Spec. Most people want RPM, Brake, Acceleration, speed and lap time. If you're going to use your data logger to diagnose problems (like I used to on Sasha Grey) then you'll really want more than just the basics. OIl Pressure, oil temp, coolant temp, Amp or Volt, EGR, AFRs all can go a long way towards helping you keep your given platform in check. Do you want to learn how to read data? I recommend to my clients to get iRacing and VirtualRacingSchool.com. Then Use both in tandem to learn a given track in a given platform. ALL of this data directly translates to reading data and comparing your laps and data to your coach's. I've found this translates into real life with most of the more popular systems out there. Happy to help, or weigh in further, but I'm best reached through email as I'm never on here anymore. dat74z At Yahoo.com1 point

-

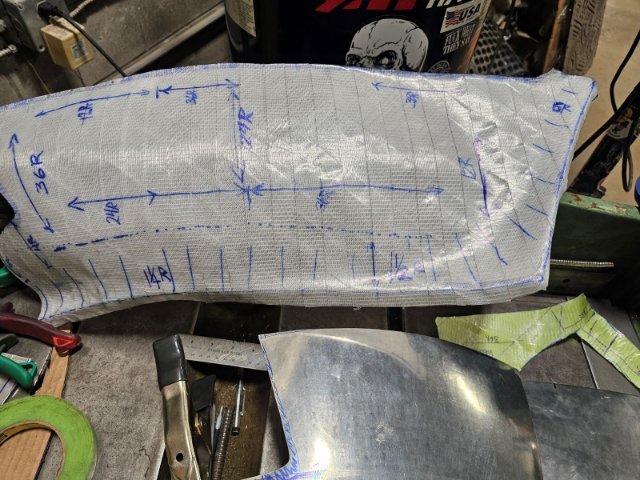

Reapairing Right Side Dashboard Ac Vent Hose- The Right AC Vent 2"Hose was broken off from the Duct Vent. So a method to reconnect that hose would have to be found. I diecided to use a 3' piece of 2" radiator to"splint' the Vent Hose to the plastic Vent Housing. Used the Hot Glue Gun to adhere the Spint to the Vent Housing. Inside View of the Splint The Finished Repair if the AC Vent Hose and Duct I had to fabricate a Micro Phillips Screwdriver to remove the Three Phillips Heas Screws to Chrome Duct Vent. This Micro Phillips Screwdriver also was used in other 'tight spaces" where normal phillips screwdrivers would not fit. Modifying the Dashboard Center Vent- The Original Center Console Vent only had a small piece of foam around the vent tube leading to the Blower Box. I decided to construct a sheet metal Tube that provide a tighter seal to Outlet Vent. Making Template for the Vent Connector Bending the sheet metal with a 5/8" deep socket to match the template shape. Finished AC Vent Connector Next-Heater Blower Fan Replacement1 point

-

1 point

-

Felt like I should finally post on this thread. 1977 280z 2+2 1. Junkyard 2004 LS1 from a GTO completely stock 2. T56 with stock clutch and new throw out bearing (from the junkyard GTO) 3. JCI motor and transmission mounts and headers. Really great kit! 4. Tanks inc fuel tank and in tank pump. DIY 7 circuit fuse block with stock GTO engine harness. 5. Started October 2018 finished April 2020 (this includes a full restoration but still got some little stuff to do) 6. Eibach lowering springs, Toyota truck front breaks, Maxima rear discs, stock diff and axles, Vintage Air AC/heat with JCI compressor kit. Thanks to everyone on Hybridz answering questions and posting stuff. This site is a great resource.1 point

-

I watched this "Ultimate Factories" show about a month ago and they were at the BMW engine factory. They were talking about how cool the aluminum block was for their I6 motor, and how hard it was to cast. A good 15-20 minutes of the show was about the block. I was surprised when they said that the block ended up weighing 90 lbs. An LS1 block weighs 92. I don't know how accurate the weight they quoted on the show was, but I know the 92 lbs for the LS is accurate. The Chevy I6 was discussed briefly a couple years ago. I think the issue was that it was too tall. Here's the thread: http://forums.hybridz.org/showthread.php?t=87482 I'm not sure if they ever pinned down the height issue or not. I still remember that Baja truck. Thing sounded insane, like an old F1 car or something.1 point