-

Posts

1394 -

Joined

-

Last visited

-

Days Won

24

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by jhm

-

For future reference, you can insert some flat spacer plates between the frame rail and the sway bar mounts to increase clearance between the sway bar and the alternator. Spacer plates out of flat aluminum plate, any thickness you want. This may give you the additional clearance you need to run the 18mm bar, if you wanted to. You can also do the frame rail reinforcement modification on the sway bar mounting points, which has a secondary effect of additional spacing between the bar and the engine accessories. You can make the reinforcement pieces yourself (which is what I've done), or buy them premade from Bad Dog Parts.

-

Sounds like the smaller/lighter 18mm bar might be plenty stiff for your needs. Are you running a rear sway bar of any sort? If you stay with using stock-sized springs, that will obviously be the main LIMDAC in tuning/balancing the car's handling. FYI for your reference: a 1" front sway bar from ST = 11.5 lb = 5.2 kg. Interesting mod....many thanks for following through on this!

-

Yes, I know Speedhut gauges are a fine product in general; however, it sounds like even if you can manage to get the fuel gauge calibrated correctly, it only reads in increments of 1/4 tank. My stock fuel gauge reads accurately and consistently, so I'll be sticking with that for now. I very much appreciate everyone's inputs on these....always good to have first-hand feedback on a product.

-

Interesting reading on the fuel gauge issue -- thanks to those who have posted here. I guess I know which aftermarket fuel gauge I will not be buying.

-

I think you're suggesting shortening your rear LCAs (and half-shafts, or CV axles) in order to achieve a shorter effective rear axle length, allowing you to run wider rear wheels & rubber without changing the exterior sheetmetal. True? If so, I think there are better ways to achieve your goals. Solid narrowed rear end comes to mind, especially if you're making big power and planning to drag race the car. Give us some more info on what you're planning to do with the car, and folks can probably help more and steer you in the right direction. Your initial post doesn't really provide much info, and just has people guessing at what you're ultimately trying to do with the car.

-

Suggest you start by reading all the FAQs -- plenty of good discussions in there on how to accomplish all the mods you are considering. You can try reshaping the rear flares, as JonMort suggested. If you do, I would consider adding a similarly-styled flare to the front....for both functionality and aesthetics. If you decide to replace, replacing the rear quarter panels is a very common repair. You can get the panels used from a donor car or new from one of the vendors that produce reproduction body panels. Good luck with it. Your car appears to be way further ahead than many project cars are at the start.

-

Looks like you've built your own fuse and relay block inside the engine compartment....are any of those circuits switched?

-

Ah, sorry -- did not realize that your car was equipped with air conditioning. My bad.

-

Joost, it's been a long time since I've had the stock ventilation system; but IIRC, all air flow is controlled mechanically (i.e. via cables between the dashboard controls and the blower assembly). Those old cable systems can get gummed up and not work smoothly, the cables can break over time, or the flapper valves internal to the blower can stick or get jammed in one position. Any of those issues could be why you're not getting hot air to your windscreen defroster vents. It could also be as simple as the heat ducting hoses falling off the heater blower or the plastic defroster ducts up at the base of the windshield. Any of these problems should be easily fixable by disassembling/cleaning/repairing/adjusting/etc as necessary without any great expense. Do you have the FSM for your car? It gives a pretty good description of the cabin heating/ventilation system. http://www.xenonzcar.com/s30.html Cheers.

-

Unless you plan on using an electric water pump, I don't think this will really achieve your intended goal. The fan will continue to run after you shut the engine off; but will really only effectively cool the fluid in the radiator vs cooling the engine. I'm surprised this setup worked on your Alfa, but I know pretty much zero about most Italian hardware. Maybe the smaller Alfa engine block and overall cooling system was small enough to be affected by the cooler fluid in the radiator. Regarding your second question, you could install switched and unswitched "hot posts" (using relays of course) to power a variety of high-draw accessories, like your electric fan, AC/heat blower fan, etc. This approach gives you a lot of flexibility in your wiring strategy, and provides max amperage directly to accessories without running through the fragile OEM switches and wiring harnesses.

-

And there's a nifty driveline angle finder in the Tremec Toolbox app for your smartphone.

-

Cool stuff....thanks for sharing! I love perusing old/original documentation, like those Datsun comp parts brochures.

-

Are these what you're looking for?

-

After you decide what you want, here's some useful links for sourcing the correct unit: https://forums.nasioc.com/forums/showthread.php?t=1969700 https://forums.nasioc.com/forums/showthread.php?t=2597453

- 5 replies

-

- drivetrain

- r180

-

(and 2 more)

Tagged with:

-

73 240z steering wheel shakes

jhm replied to milesz's topic in Brakes, Wheels, Suspension and Chassis

Wheels out of balance seems to be the obvious answer, in most cases. Other possibilities include flat spots in tires, rims that are bent, worn steering rack bushings (the mounting bushings that are used to clamp it to the front crossmember), worn steering coupler, worn out shocks. -

Amp gauge and indicators question?

jhm replied to Whitley_280z_2+2's topic in S30 Series - 240z, 260z, 280z

Sorry, I didn't watch your video earlier; but just watched it now. Looks like you have a Voltmeter, vs an Ammeter (i.e. "Amp Gauge")....is that correct? Two different gauges that measure two different metrics. Typically, a voltmeter will react much less to changes in system amperage draw than an ammeter. From your video, I'm guessing that the engine was NOT running when you filmed the video? Is that correct? If so, I would try the same test again but with the engine running (and the alternator charging). You should see much smaller (and possibly none) fluctuations in the voltmeter reading, because the alternator/voltage regulator will keep things more stable in your electrical system. And obviously, the voltmeter should be reading somewhere in the 13-14 V range with the engine running. If not, there's a problem with the battery charging subsystem. Hope this makes sense. If not, feel free to ask more questions. -

Amp gauge and indicators question?

jhm replied to Whitley_280z_2+2's topic in S30 Series - 240z, 260z, 280z

Yes, completely normal. Any change in system draw will cause the Ammeter needle to move around. -

Not sure from your photo, but is it this sensor? https://www.carparts.com/details/Nissan/280Z/Replacement/Coolant_Temperature_Sensor/1976/SET-RB31280001-2.html?utm_source=connexity&utm_medium=cpc&utm_campaign=affpla&TID=zlaaff

-

Front strut replacement questions

jhm replied to Tarheelz's topic in Brakes, Wheels, Suspension and Chassis

I may have misunderstood your original post. Is the rust inside your strut tube (where the shock is installed), or on the underside of your strut tower? My earlier response assumed it was the latter; but now I'm thinking it's the former. Sorry, my bad. As Newzed stated, you can remove the rust mechanically; or use a liquid chemical product to neutralize the rust. After it's cleaned up and painted, a little oil inside the tube will help prevent future oxidation and help with heat dissipation. -

Front strut replacement questions

jhm replied to Tarheelz's topic in Brakes, Wheels, Suspension and Chassis

If you wanted, you could put one PU bushing on the "front" of the TC cup, and leave your new rubber bushing on the backside of the cup. This minimizes the risk of damaging the cup due to the inflexibility of PU. Regarding your second question....I don't know what your definition of "quite a bit" is; but how about removing the rust, painting, and if necessary, weld in some reinforcement sheet metal? It's a pretty simple shape, so it should be easy to cut and fit the reinforcement pieces. -

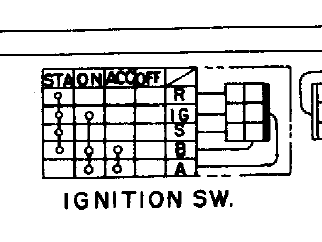

Sounds like a loose connection somewhere in the ignition circuitry; judging from your statement about driving over a speed bump. WRT your question on the ignition switch/lock: no, I don't believe that would contribute to your issue. Once the ignition switch is moved to a particular position, those connections are completed and it doesn't matter whether the key is in the switch or not. My key is very worn, as well, and I can remove it from the switch anytime without any affect.

-

White smoke and coolant from exhaust.

jhm replied to Sjoost's topic in S30 Series - 240z, 260z, 280z

Hey Joost- Sounds like the problem started after you fixed some coolant leaks in the vicinity of the fuel rail? If so, maybe relook those repairs to ensure the repairs themselves weren't the cause of your issues? Have you had to refill your coolant during these tests, or is it maintaining a constant level of fill? Liquid in your exhaust during first couple minutes of startup is not all unusual, as NewZed pointed out, and can even be caused by nothing more than atmospheric condensation (usually from the previous shutdown). If this is what's occurring, it will be water only. If you can detect actual coolant in the liquid in the exhaust (I don't know how one can definitely do that), then you likely have a problem. A good way to monitor engine temperatures is with a simple IR thermometer, especially if you're not confident in the temp gauge readings. You can use the IR unit to check temps at various points....radiator, coolant lines, engine block, etc. Good luck with it. -

Good question. Was wondering the same thing myself. @RTz, @SuperDan, @stony, @tube80z

-

Not a website, but this may help some with parts list and prices. (You need to be a FB user.)

-

LS1 T56 240Z springs, what to run? No Coil overs.

jhm replied to Richard Oben's topic in Gen III & IV Chevy V8Z Tech Board

No, the d-shape is to keep the shock shaft from spinning whilst tightening the top locking nut. I don't know about Koni Yellows, but the stock hole should be compatible with the shaft on KYB, Tokicos, Sachs, and other popular strut inserts made for the S30. Bilsteins are an obvious exception, due to the large shaft diameter and top locking nut.