calZ

Donating Members-

Posts

661 -

Joined

-

Last visited

-

Days Won

19

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by calZ

-

What year is your car, manninen?

-

RockAuto has it listed at 8.75", or 222.25mm. The bolt pattern is the exact same on the Toyota booster as the 240Z booster. There's some discussion about it and then bawfuls installed one in this thread:

-

Front brake upgrade with slip-on rotor

calZ replied to calZ's topic in Brakes, Wheels, Suspension and Chassis

The surface that contacts the innermost brake pad. I have Z31 hubs that I used to mock up a wheel speed sensor add-on, but yes, I'm waiting on some 5-lug hubs from T3. -

Front brake upgrade with slip-on rotor

calZ posted a topic in Brakes, Wheels, Suspension and Chassis

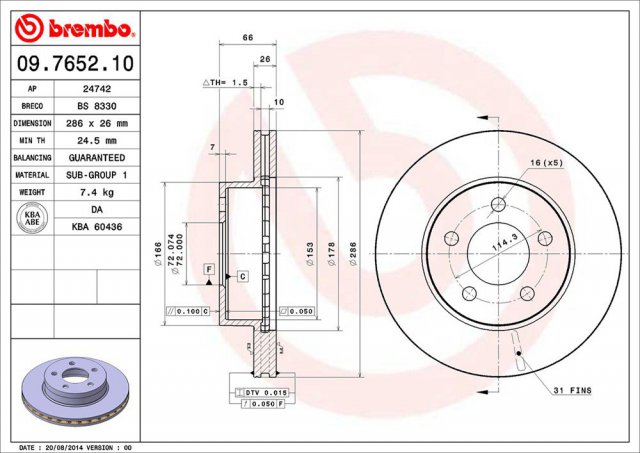

Has anyone ever used a slip-on rotor on the front? I've been interested in making it happen since it would match the rears(T3 Q45 swap), and it would mean I could pull the rotors off without having to mess with the wheel bearings. I found a rotor that I think would do the trick. It's a front rotor for a 99-01 Ford Explorer and has 0.2mm clearance on the center bore and 0.6mm on the outer hub bore. The rotor is 26mm thick instead of the standard 28mm the Q45 front calipers are made for, but that's not an issue. The inboard face of the rotor would end up ~10mm further out than stock, but I don't think that's in an unreasonable spot. Thoughts? I'll attach the drawing of the Explorer rotor below. Btw, the European Brembo site has a "search by size" option for rotors. Great tool for coming up with custom brake solutions. https://www.bremboparts.com/europe/en/catalogue/size?producttype=Disc&th=28&a=68&issizetolerance=True -

Picked this up recently. NOS from Japan. It's likely going to stay in its box in bubble wrap on my shelf for quite a while at the rate my car is being finished.

-

Zcardepot is doing 10% off their entire store, and silvermine has some items on sale as well.

-

1997 Toyota Tacoma booster and master bolt in and the master is 1" if you're simply looking for a bigger master.

-

He's asking if you're sure your cam is timed properly. In other words, is your camshaft position lined up correctly with your crankshaft position.

-

How are you going to control this? With the original E30 computer? I've been exploring ABS a bit but haven't found something very tunable other than the expensive Bosch setup.

-

My thoughts as well. Why make a tubular control arm and not continue the tubes all the way to the pickup point? That plate doesn't look thick enough to me.

-

What? You can just click the link and look at items. Are you sure you didn't click an ad on the page or something?

- 11 replies

-

- skillard

- retro spec

-

(and 2 more)

Tagged with:

-

I emailed T3 and confirmed with them that they use the standard 5x103 pattern, so that's great news. I also test fit the hubs onto my car over the weekend. With the turbo hubs, they clear the dust shield by over an inch. That means they might get pretty close the the spindle with 5-lug 280Z hubs since they're lower offset, but I think you could play with the adapter thickness to get clearance if necessary. The round part of the spindle is not much smaller than the tone ring, so some clearancing might have to be done to get a sensor in the right spot.

-

I don't think so. When you have the 4-lug pattern, the rotor bolt holes get super close to touching the tone ring bolt holes. Add in the material on the "legs" of the tone ring and there's not room to get a rotor bolt in.

-

Do you have a picture? All the front brake kits I see on their site seem to have the outer 8-hole pattern to bolt the rotor to the hat, but I think the hat still uses a 5-hole pattern to attach to the hub.

-

So, it turns out the hole pattern isn't that oddball. It seems to be simply 5x110, but one of the threaded holes on the tone ring is drilled off-center. This caused a bunch of headaches until I figured it out. Always nice when OEM parts have issues. Drawing is attached. You might be able to tighten up the radii of the bolt holes a bit, but it all depends on what type of tolerance for part imperfections you want. Thickness and countersinking would depend on your material and application, so I left that out of the drawing. The inner and outer radii of the adapter itself don't need to be exact, and might actually vary depending on your hub and rotor. Basically, everything in here other than the 5-hole patterns aren't test fit for other applications, so use without verifying at your own risk. SubaruToneRingAdapter.pdf

-

BHJ is running the business side for them so they can focus on making parts and catching back up. They promise RetroSpec parts with actual professionalism in terms of ordering and updates. You might be able to go through them to get an update.

-

I would talk to these guys.

-

Why do the bots all go for the same post?

-

Quick count looks like 44 teeth. Do you know what the rotor bolt pattern is? Stock is 4x103mm, and the 300zx hubs are 5x103mm. SilverMine uses the 5x103mm pattern on their hubs, but I can't find measurements for AZC or T3. I did find SilverMine blog post from 5 years ago claiming T3 uses 5x3.85", which would limit rotor choices to only T3 stuff. They may have updated since then.

-

That's the link to the image mentioned above. I'm not sure it it's for an S30 or S130.

-

I'll put a drawing up when I get everything figured out. I thought about making these to sell as a kit, but since everything seems to be working without modifications it hardly makes sense. I'd just be reselling OEM parts minus the spacer. One more hurdle is that the test fit was on 300ZX turbo hubs. I don't have a pair of 240Z five lug hubs to check clearance on, so the rotor clearance could be different there. Maybe I'll pull off my 4-lug hubs this weekend and give it a look.

-

6.5mm. I think on the second iteration I'm going to go thicker so I can countersink the bolt heads. I've yet to throw the hub on the upright to check for clearance and how to mount the sensor, but I don't foresee any issues there.

-

Forester, but yeah. Good call on that.

-

Update with pics! So the adapter finished printing. I should have taken a picture of the shiny finished product but didn't. I can't now for reasons to be explained soon. I'll attach a pic of the in-progress print. Initial test fits made me think I didn't have a chance to get to the heads of the rotor bolts once the tone ring was on, meaning I'd have to attach the tone ring from the top. Because of this, I left the ring-to-adapter holes small enough to be tapped. There was more space than expected, so I was able to run down the rotor bolts with a 1/4in drive socket at an angle on the head. This won't work when you really need to torque them down, but that's easily solvable by converting to socket cap screws instead of hex head. The tone ring hole pattern is some oddball radius, so I'm still working on that. When drilling the holes to expand them enough to get the bolts to go in, I kind of blew out a couple holes and cracked the adapter ring. Apparently resin printed parts are a lot more brittle than FDM ABS parts. I'm going to print some 100% scale drawings and match the hole pattern up with paper before I print another adapter ring. Long story short, here are a couple pictures of the tone ring mounted. It fits these turbo hubs like a glove.

-

Good timing. I picked up a tone ring last week and worked on an adapter this weekend. I'm going to need to drill through the original mounting holes of the tone ring so it can be fastened from the top, but it should work. I'll have to make some angled spacers/washers for the final attachment, but I'm 3D printing a prototype adapter ring on my resin printer right now. It just barely fits in the build area.