Leaderboard

Popular Content

Showing content with the highest reputation since 12/10/04 in Posts

-

Don't tell my wife Like I tell other people. some like to fish, some like to bowl, I like to make.6 points

-

He's saying although we are launching a DOHC head in 2024 we readily admit it will be pale in comparison the mighty KN20 from Datsunworks. At least that's what I'm hearing.4 points

-

4 points

-

**UPDATE Went to court yesterday and basically played dumb. Told the judge that "I went to the state ref and he told me since the car is so old that he couldn't do anything to certify it. So how do I go about taking car of this ticket. The vehicle is a pre smog vehicle so I've never had to SMOG it" The judge said "Ok so what Im going to do here is dismiss the case cuz it seems like your car doesn't qualify for an inspection. Sorry about the inconvenience Mr. Soto" I tried to play it cool but I was so happy. After reading all the horror stories from other people about having to revert to stock and all that I was lucky I guess Hope this thread helps someone going through something similar4 points

-

Greetings Everyone, Due to the increase in spammers HybridZ, registration has changed from being automatic to manual. That means one of the Admins will need to approve any new registrants. If you ask or tell someone about HybridZ (please do) let them know registration isn't automatic anymore. We'll do our best to stay on top of any additions and hopefully you all will see a lot less spam. Thanks, The HybridZ moderation team4 points

-

3 points

-

Unfortunately, it is too late. Maybe for round 6 in a couple of years Got the shirts in and will start breaking things down and shipping things out next week. This week is busy with work travel, so appreciate your patience while I get a few out each day on my lunch breaks.3 points

-

They received all of the shirts without backorders and are starting on printing this afternoon!3 points

-

I really wish things would swing back towards the forums. I can't tell you how many times I know the answer to or could add to a post on FB but I don't since it really has no longevity. I always felt like I was adding to the overall knowledge base when I posted here. I can go on and on but I really hate it.3 points

-

First start up since starting the restoration. Kind of shocked she started right up on the first go. Was expecting something on the MegaJolt to need fixing, but it worked great. Went with Magnacor wires, but they made a mistake and did not fit them up with the right coil boots. Being remade and shipped, so I am using 05’ ford explorer NGK wires for now. Went with a “7” heat NGK plug on account of the 10:1 CR. It’s raining this weekend, but just need to dial-in some crude alignment and she will be road worthy IMG_2339.mov3 points

-

Just wanted to say again a HUGE "Thank You" to @cockerstar for doing this (a FIFTH time)!!!! Really appreciate all his time and effort to make this happen. You da' man, Ryan!!! 👍👍3 points

-

3 points

-

I want to thank all of you here for giving me inspiration for my build. I have adopted the Hybrid Z name for my build years ago since this site provided a lot of information that I consider priceless. I was able to meet some great people at ZCON, some that know my build and others that just wanted to say hello and compliment me on my build. When I built this car I built it as my version of what a Z should be therefore I know a lot of people were not going to like it since it was my vision and nothing else. Taking my car to ZCON for the 1st time and walking out of there with these awards it’s just incredible, especially with all the awesome cars I was competing against. It’s great to see the judges appreciate all the hard work and effort that has gone into it. These are the awards I received. 1st Place in Ultra Modified Best Engine Gold Cup- This was totally unexpected and shocking it was given to a Z with and LS3 since most of these guys are Nissan purists. Again, thank you all for your support and keeping this site alive.3 points

-

Update : I had been fighting an erratic wideband on the rear collector -cylinders 4-6. Well it turns out I still had a leak at the collector which is before the O2 sensors - dammit . This is a Z story header and collector . The collector pipe was modified for my exhaust and I thought I had the flange true , but it still leaked . This time around I eliminated the gasket all together and used Red Loctite only . At the same time I had a new O2 sensor installed since I was that deep into it . I DID see evidence of a leak but changed the sensor anyways . FIXED! This change helped so much with the tune and you could hear it ! I was able to get the banks to harmonize much better with AFR’s and sound . This helped to mitigate the drone I was getting at low rpm cruise . I thought this would also fix an issue I’ve seen on every intake I’ve used where the AFR’s between the two O2 sensors would be different during high vacuum running - light cruise . Megasquirt didn’t seem to be able to compensate in those scenarios though I had two separate O2 sensors dividing the banks . I ended up going into the injector trims and adding fuel to 1-3 since they ran really lean under high vacuum . Maybe they suck all the air out of the plenum before it reaches the last 3 cylinders . I added almost 20% to 1-3 . At this point the AFR’s evened up and you could feel and hear the difference . This is probably the best I’ve had my L running . Happy guy right now2 points

-

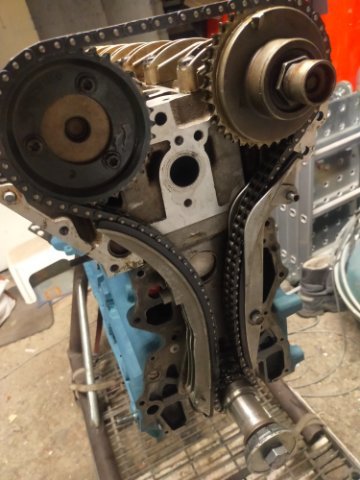

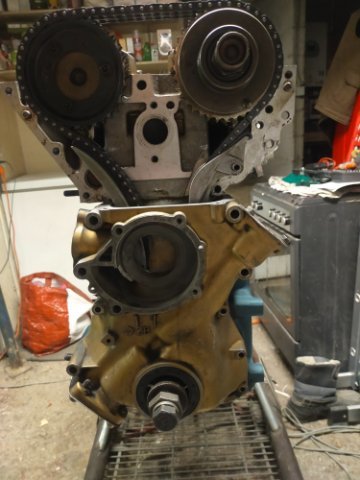

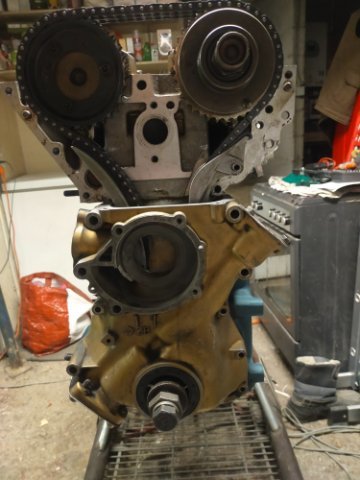

well yes , stock guides , just to make lower axes in the block, and the stock cover is modified to make some space, electric water pump ( davis Craig ) , and tensioner on the right side, in place of the water inlet ( spring and lock without oil pressure ) no need for oil pump drive or distributor for i put dry sump pump system and megasquirt ignition and injection EFI with yamaha bike itb's So simple and cheap , just a little of brain storming ! oh ! and a little joke for the head cover !! Lol !2 points

-

There is no swap hardware to put the Z transmission behind a V8. It wouldn't handle the torque anyway. The 260Z engine is about 158 cubic inches, compared to 350 for a SBC. The old Z transmission bearings are typically ready to fall apart besides that, not uncommon even with the stock engines. It would probably last about one pull. I haven't done it myself, but I wouldn't even try it just based on what I've learned.2 points

-

You have packed a lot into your intro. There's some good advice below to consider in the posts to your question. But I have to ask you what is it about the 280 you love? I don't mean that coyly or as some flippant remark. What is it you really like? I'll give you why I like the Zs. I grew up around them when they were new, my uncle was a general manager of a Datsun dealership so we got to try out the new cars. We raced with my uncle at autocross and hillclimbs (I was a kid so I just went along). Back then the Z cars were fast and sounded awesome (I have the hearing loss to prove it), and were amazing at cutting through the corners both stock and modified. Our local racing club had about 10 people driving stock to all-out racing versions. 50 years pass and a lot of that coolness has mostly worn off except for the look of a lowered S30 with an airdam and rear spoiler. I have to admit the sound of a modified Z makes me happy when I hear it. But this site exists to help people get the most out of them. And the reality of that is as cool as the L28 engine is you're looking at spending a lot of money and you'll have an engine that makes 200 to 250 HP. Sure you can get more but then all the other parts that connect to that engine are starting to get pushed past their limits given the age. While I don't disagree with any of the posts below you should still read about a lot of the mods and why they were done. You'll find that in many cases they were driven by it costing too much, parts NLA, etcetera. A bit of advice from me. Never by an engine, transmission, or rear end unless you plan to use it within a few months. Even if you plan to use it that's not the same as ready to bolt in. If you want a street car with a certain coolness and triple Weber carbs, then build it. But when you spend 10K on an engine and find it's somewhat finicky to drive but cool all the same. But for less, you could have 350 HP V6 in the DI Chevy LV3. It won't sound the same as the L-motor but it's lighter, a lot newer, and will get excellent mileage, It will start anywhere if it's hot or cold by the sea or at altitude. This site has a ton of info on how to do the same for the suspension and how to get a cheaper rear diff, especially if you want an LSD. I could write a lot more but this is probably too long as it is. Welcome to Z ownership. Cary2 points

-

Yes, with the carbs you can get rid of the ECU and EFI parts. The complete EFI harness can be removed. The guys that know on the site (from the past) say that the exhaust system is restrictive and opening it up helps a lot (see John C posts from the past) , and that if you decide to use a performance cam go big (see JMortensen posts from the past). The typical "Stage" 1 or 2 cams don't add much, apparently. So, the simple and effective way to add some power is with a better exhaust system and a big cam. Cams are more expensive than they seem because you need to buy lash pads and rocker arms along with the cam. The collection of parts costs can add up. But it's a pretty simple operation to get it done. Many people like the lighter flywheel. It takes more finesse on the clutch pedal but they say it's worth it. Fidanza is a good choice. For street driving an LSD doesn't add much. You might wait on it and see if you have traction problems. There is a ton on the site from the old-timers, around the 2000 to 2015 time range. Things have slowed a lot on the site as people have moved on. But their contributions are still here. Many of the guys were racers and/or engineers/mechanics/machinists and spent a lot of time and money on their projects. Today's car hobbyists really only know turbos and EFI since that's what they were raised on. Good luck.2 points

-

Life has been kicking my ass lately! Between my job changing significantly, being super sick, and some significant medical issues with my daughter I haven’t made the progress on shipping orders that I have wanted to. Post here if you’re really itching to get yours and I’ll move it to the top of my list. Otherwise I’m moving along as ordered. I’d like to get these wrapped up so I can transfer the remaining funds over to Dan.2 points

-

We’re going on track this Sunday at Willow springs Will set-up the car tomorrow at a friends shop since they have a flat-level garage floor (which I do not). Also in the middle of adapting the front brakes to 280zx rotor and caliper per EP spec-line. Caliper mounting on the strut assembly will require some welding and drilling, so it will have to wait till after this weekend. Greg Ira was nice enough to ship me some race pads he has that fit the OEM calipers.2 points

-

2 points

-

Hi everyone! I have the shirts and should be able to start getting some out today. I was primarily working from home at least 80% of the time, but my job just got pushed to 60-80% travel so I haven't had breaks at home like I used to.2 points

-

Well, after more testing, it seems to be a user error. Was able to drive for a good hour today without and bucking/shudders. I think it's a combination of a new clutch and upgraded transmission/rear end that I have to get used to. The car seems to like higher rpms when starting from a stop, and a different clutch engagement that what it was before. Car is much more fun with the new parts. Not a fast car, but a fun one.2 points

-

No, you just pull the bearings off of the front of their shafts. The countershaft bearing is pretty tight to the gear and takes some trickery. The mainshaft bearing needs a puller with long arms. You can push the rods back to get more room. The transmission will have multiple gears engaged but it won't matter. When you reinstall the front case put it in a single gear (one rod moved) to avoid locking up the transmission by accident. Here's a decent video about the countershaft bearing, different tranmsision but same concepts. He did the same thing I did, clamping a two jaw puller in to the gap, otherwise the jaws pop off. The mainshaft is a more normal operation but the length of the shaft has to be managed. It takes some work. If you have friends that have pulled bearings or gears it might be worhtwhile to get some more ideas and tools on-hand. Notice the odd combination. Go to 4:00 if it doesn't start there.2 points

-

4th gear doesn't use the countershaft, it's direct drive. That's a good clue. Sounds more like the countershaft bearing. Looks like you'll need to split the cases, so you might as well do the mainshaft/input shaft bearing also. It's not a super-finesse job. Just needs some ingenuity. It's fun. Part of Z ownership. Here's a good illustration of the parts you'll be looking at. I'm sure that there are "how-to" videos out there somewhere. You can get a factory service manual on the internet that shows how to take it apart. Good luck. https://www.zhome.com/ZCMnL/tech/240SX5spd/Transmission2.htm2 points

-

Order is with the screen printer and will keep you guys posted when I get an ETA on delivery.2 points

-

Finally got this thing tuned right, kept fighting an issue where the car would break up on quick throttle changes and in boost. Engine had NGK b6es-11 plugs, I went to a NGK bpr7es and all my problems disappeared. Engine is leaking oil pretty bad though from what looks like where the timing cover and cylinder head meet, l am genuinely amazed at how much oil can come out of there. The stock head gasket was torn there, and I RTVed it up a lot after the fact. Maybe my PCV valve is faulty and pressurizing that area under boost? Once I get this oil leak handled Ill take it to the dyno.2 points

-

2 points

-

@calZ, I spoke with John yesterday and I'm going to do another round. 36 item minimum from my print shop, but I think we can hit that!2 points

-

I am still around, I don't check regularly. I still have my Z. I joined here when I was 15, I am about to turn 38.2 points

-

2 points

-

2 points

-

I welded 4x 1.75" wide 0.06" thick strips from the roll hoop to the body, two on the sides right below the window frame and two to the roof support .75" outboard of the dimple die holes. I cannot believe how much quieter the car is and how much better it handles bumps, hard accelerations, sharp turns, etc. Its really incredible, wish I'd done this a year ago.2 points

-

Car is still around. Still drysumped LS2, jenvey throttles with quaife 6 speed sequential and independent 9 inch. 18 x 11 wheels and 300 mm slicks all round, big AP brakes. Cool car, but the process over 9 years has been expensive. 3 x R200s, 3 t56 gearbox’s, 3 sets of coil overs, 2 sets of brakes (plus numerous rotors and pads -last set of maintenance rotors and pads was $3400. I motor blown due to oil pressure, one due to a lifter, one cooked, but still ran. Driveline is not bullet proof, but works hard so requires a little maintenance. Video is what I class as a diagnostic video. It also happens to show a Z doing a 2.18 lap around Bathurst. My quaife had dropped one tooth on 3rd gear.2 points

-

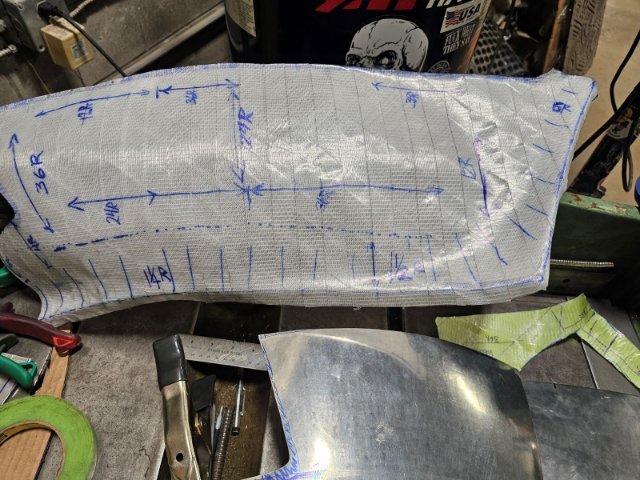

For this build I decided to jump in with both feet and learn how to build fiberglass. I found out early on that I would need to build up a custom air dam so I decided to build out a door as a trial to learn the process. I have done plenty of small FG projects but never something large that involves building a mold tool. You can see the process in the pictures. First sanding and waxing the door (plug) and applying mold release. Then a layer of gelcoat and then laying down multiple layers of heavy matt until the mold has enough strength and rigidity not to break when pulling the final part. The only mistake I made was not smoothing out the original door. I thought it looked fairly straight but it turned out to have some waves in it. It also had some small flaws I thought would be easy to correct in the mold. I was dead wrong. It would have been much easier to correct the flaws on the original door than to work on the mold. You can see the final surface on the mold. Then I prepped the mold, laid in some layers and a new door popped out. It's hard to tell in the pictures but the surface finish turned out great. I added some cardboard rolls in the back to make it stiff. It is attached to the car with push button locks and pins on the bottom. For the final touch I 3d printed a door handle.2 points

-

It would be helpful certainly, but I think in general, Apex and Techno (to name a few) aren't making parts which require that level of explanation. Quick steer knuckles, adjustable sway bars and RCA blocks are about as intense as anyone has gone until Apex started doing their subframes, allowing for roll center adjustment. Otherwise, listing a spec as "Up to 4* more camber over stock" or "3" wider front track than stock" or "Stronger!" are just, to my mind, stating the obvious. As a counterpoint, GKTech who makes a huge variety of drop knuckles and extremely modified components does a fabulous job detailing their R&D and decision making: https://blog.gktech.com/blog/gktech-rear-suspension-uprights/ I think if companies for the Z were making parts like this, it would make sense to detail choices.2 points

-

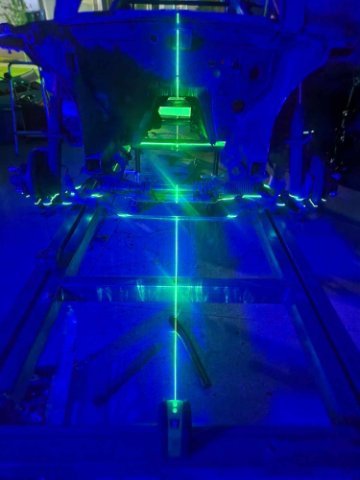

So I made a laser alignment tool based on a few Ideas I gleaned from the forum. I made a slip collar that fits over the CD009 output shaft that holds a 45ACP laser bore setter. I'm using this for the horizontal alignment. Works well. I made a target that has a couple of alignment lines. The bottom is parallel/perpendicular to those lines so you can use a level to get it plumb. I then proceeded to drill so many holes in it that it's almost useless:) The key word here is almost. That was a far over to centerline as I could get it. I need to rework either the Diff mount or the trans mount to get it any further but it's only about a half a degree so I may live with it. I'm running the Technoversions RT mount and I switched to the top mount instead of the stock bottom. This brought the pinion angle down to 2.8 degrees. The transmission is at 2.9 degrees so I'm pretty satisfied. Hard to tell if it made much of a difference but the math says it should.2 points

-

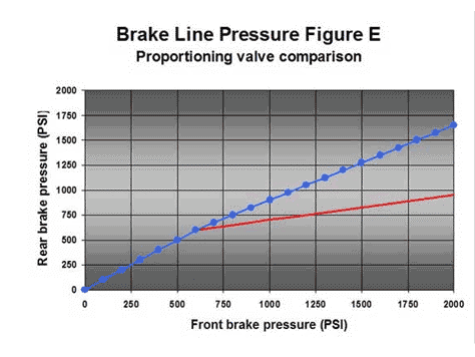

As I mentioned on the previous page, a prop valve in the front is never a good idea. As brake pressure increases, the proportion of braking done by the circuit with the valve decreases. With a valve in the front, the harder you hit the brakes, the lower the percentage of front brakes you get. This is not good, because the harder you hit the brakes, the more weight transfers to the front wheels and off of the rears. So the wheels with less traction get an increasing proportion of the braking effort as you step on the brakes harder and harder. "Proportioning Modifications We could start this section by clearly stating that you should not modify your proportioning valve. But, what fun would that be? In all seriousness, making changes to the proportioning valve to effect brake bias should be left to those with the proper tools and measurement devices, but if you have tweaked your vehicle beyond recognition, this may be your only solution to restore a sense of proper bias to your braking system. We’ll start here with three of the most basic rules regarding proportioning valve installation and selection. 1. If you have the deeply-rooted need to install your own adjustable proportioning valve, be advised that they should NEVER be installed if the factory unit is still in place. Proportioning valves in series with one another can do nasty, unpredictable things! 2. If you have the deeply-rooted need to install your own adjustable proportioning valve, be advised that they should NEVER be installed in-line to the front brakes. The effect would be to make your vehicle rear-biased before you could say “terminal oversteer.” Front brake line pressure should always be left alone – only the rear pressures should be considered for proportioning. 3. In all cases, the basic brake system balance needs to be close to optimized to start with. This is the only way that a proportioning valve can be effectively utilized. You should never assume that simply adding a proportioning valve will address all rear-bias conditions, as even the best proportioning valves must be well-matched to the target vehicle." https://www.apcautotech.com/getmedia/d958a29e-4ebf-41fd-931f-bf7e4451801b/brake-proportioning-valves.pdf2 points

-

Found a site for downloading the FSM that I have never seen before, with a lot of nice information, link below http://240260280.com/Docs/2 points

-

The plan was to do some track days this year, so I needed some brake ducts and an oil cooler. I sold/bartered a set of series 1 scooped backing plates I had for a set of normal ones. No need to cut up the rare stuff. Took the new backing plates, cut them to 8" diameter, took a 3" exhaust collector and modded it to fit the cut down backing plate. Welded, drilled holes in the duct hole and then used cut off wheel and die grinder to open the hole in the backing plate up. Also took a section of the rim of the stock backing plate and welded it on for stiffness and to close the gap between the backing plate and the rotor vents. Doesn't look all that wonderful but I think it's going to work well. 1 down, 1 to go, then can modify my front end for the scoops and hook up the tubing.2 points

-

2 points

-

Thanks to everyone that purchased a piece of apparel in the fundraiser to help @SuperDan with operating costs for the site! We sold a total of 88 shirts with a resulting profit of $1202.19, which I just sent 100% of to Dan. It won't show as a donation because I sent it via friends and family to ensure every penny made it to him. This should cover the site's costs for about 6 months. Moving forward, I'll be doing an annual apparel sale with 100% being donated towards operating expenses. Each year we'll do a different promotional item since many of you now have several HybridZ shirts in your closet! Looking forward to hearing your ideas on what you'd like to see along with the shirts. Hats, beanies, keychains, stickers, etc all come to mind.2 points

-

Semantics is a big deal on this forum. It is one way that separates us from other forums. Making sure an item is called the correct name that people recognize will go a long way. If you want I can edit the title of your post which directly asks for a workaround to the combo switch. Semantically it seems to be called a multi-function relay. The relays themselves seem to last quite a while, I'm still using several stock ones in my 71 that was in use till 2010. I would suspect as miles pointed out it may be the switch contacts on the stalk going out. The hazard lights switch has its own set of wiring so it may be acting as a red herring if you are using that as the reasoning in your train of thought. I suggest taking a breath, people are here to help of their own accord, it may be frustrating to seemingly answer the same question or when someone is caught on a seemingly unrelated point, but realize we need clarity to try and help. It may serve to help their train of thought, and it may seem tedious, but given the free help, maybe try being accommodating? It may serve better to have a post where you clarify exactly what you are looking for that you or others can refer to someone asking a question in the post. I can't answer as I've only looked at the early Z wiring in detail, but it seems odd for the blinker wiring to go through the floor so I can identify with others as to the confusion. I'm finding a note that the part number was used for a fuel pump relay, might be something else to check. I do know the pins are a standard spade connector so you could wire in a modern relay if you can pin out the contacts and make little adapter lengths, I've done that for some older plugs before. Identify power, ground, switch ground, switch power, and output. Then you can use any modern automotive relay.2 points

-

Did it. Not a bolt on deal, but easier than a LS1 swap! Nobody here should be scared. rear parking hat brakes2 points

-

2 points

-

2 points

-

Machine work finished! I can relax a little:) Just got done with their first bath. Still need de-buring and edge finishing but the majority of the work is done. The VCT holes are drilled and tapped but they haven’t been drilled all the way through. Easily opened up with a drill if needed. The head has provisions for three sub plates. Timing chain idler, upper tensioner and a slack side guide pivot. The idler and tensioner are connected to the oil system and o-ringed. It is getting really crowded in there with all the oil passages, head bolts and cam tower bolts. Next stop vacuum resin impregnation.2 points

-

Ready for battle! Getting geared up to start machining the heads. Officially the first production run.2 points

-

With all do respect newzed you have contrbuted nothing new to the solution of the problem that I had not already addressed many weeks back with DSS. I may not be using terms that agree with you.... I said “bind and won’t turn” and you prefer “won’t spin”. Your suggestion of filing off a dust cap is impossible as we are talking about solid billet machined parts that are meant to be to spec. You just can’t take a file to this stuff and call it good and I don’t own a lathe. I purchased these parts at great cost per DSS selling them as bolt on and in regularly use on many S30 Z’s. They have since admitted that they have NEVER had this stub axle on 240Z and admitted that there stub axle was previously copied off of an unknown Datsun stub axle they were told was an S30. I have supplied them all of the measurements using my mics and calipers for the risers so the bearing would fit per spec. Unfortunately, the first riser was not machined to measurements I provided so they did them a second time, this time per my measurements and they are perfect. Great, however the billet machined shoulder then cam into contact with the housing and again would not spin. Soooooo I sent them a stock 240Z OEM stub axle along with their axles with the understanding that DSS would machine into the billet stub axle the proper recess and width allowing the stub axle to fit as OEM with the stock stamped dust cap. DSS sent the axles back to me with shoulder machined down but without the necessary recess. I called them concerned they still would not fit however, per their instructions, bolted them back up as they were “within .005 tolerance of OEM”. I bolted them back up and they continue to press against the housing and will not spin. I called DSS with the bad news and they said “sorry, we didn’t think the recess was that important”. My response was “why didn’t you just machine the axle to match the OEM one I sent”? There Response- “Im not sure i need to talk to the machine shop”. As of this afternoon, DSS has requested I send it all back one more time and they will make it right. I’m going to give them that opportunity again as I am to far into this to just turn back. So, after month of emails, pictures, and sourcing hardware to fit (since the supplied hardware hits the differential on the adapter side of this conversion) I am again hoping that DSS machines these stub axles to OEM spec. Keep in mind, this is advertised as a “bolt in no modification kit”. Im really not offended that I’m not making sense to you. I’m offended and ticked off that I was sold a product that has never actually been bolted on to a 240Z and that I have been patiently (admittedly sometimes not so) trying to help them produce a useable product from the other side of the U.S with phone calls emails and pictures. The final straw is sending them an OEM axle with the instructions “make a copy of this” and it still came back machined wrong. Every point you have made regarding bearings and risers and clearance I agree with fully and in fact I communicated to them to fix those issues as they arose. It’s been a long process. I’m sorry I can’t satisfy your deepest need for every piece of communication and I honestly can’t tell you why they keep getting it wrong. Funny thing is, they can’t explain it either, but they sure as heck are not blaming me. Lee thanked me for my patience with all of DSS mistakes. Getting into a war of words is not my bag. I’m bummed out this crap is clogging up the forum. I apologize if I offended you. I’m really just a hard working guy that loves Z’s and gearhead culture in general. I’ve been building and racing for most of my 50 years of life (first kart and motorcycle age 5) and building cars in my garage is my therapy..... supposed to be fun. Given all my frustration with this purchase, i just needed a place to vent and I really want others to avoid the same. So hearing that I’m a whining complainer that doesn’t know what the hell he is saying and is incompetent to turn a wrench hits where it hurts to be perfectly honest. Agree to disagree is cool with me, time to let this squabble go. With respect, Jim2 points