NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

Fuel Rails on an LS3 and best way to run

NewZed replied to cooperma's topic in Gen III & IV Chevy V8Z Tech Board

Dead-head could be a problem with an Aeromotive regulator. They leak down immediately. The rail will be full of vapor on a hot engine and won't refill quickly. An FPR at the end of a long rail feeding eight injectors could have pressure consistency issues, across the injectors. Hard to rationalize which end would be high or low since the FPR is at one end and the pressure supply is at the other. But if the rail internals are small you could imagine a pressure drop at the end if the injectors in front use all of the pressure faster than the pump can build it, like at open throttle. The FPR can only close up completely to allow pressure to build, but the pressure has to build from the supply side. So you'd probably want a large diameter rail. Just a thought. -

Overfueling or flooding is one way that ECU's die. Could be the injector transistors are shorted, or, apparently, the solder joints at the cable connection point. People have had a milder case of the problem (running way too rich) and fixed it temporarily by beating on the side of the ECU or wiggling the main cable. I had one die while I was test-driving the car and the guy that helped me push it off the road said he could smell a lot of gas. It died and restarted about three times then died for good, before I pushed it off the road. Ran home and picked up the good ECU, swapped it in and drove home. I put new transistors in (not direct replacements, just an experiment) and it worked. Just an aside. Several people have reflowed the solder joints at the connector and fixed a similar problem. Anyway, if you confirm that the injectors are dumping too much fuel only when they're getting the signal from the ignition system (engine cranking or running), odds are it's an ECU problem.

-

A V6 transplant in to a Z car isn't the best starting point for "learning about engines". Get a 280Z with stock EFI and you'll learn a ton about the basics of electronic fuel injection, electronic ignition, and engine mechanicals on an engine you'll actually have room to work on. Then choose a path to another engine and more power. You'll be better off in the long run..

-

I wrote a while thing about injectors then realized that the most likely suspect is your FPR. It's blown and allowing fuel through the vacuum hose when the pump is running. Try disconnecting the vacuum hose and see if fuel comes out when you recreate the issue. I also get the impression that your pump runs all the time when the key is On, and may have been rewired. So the intake manifold would start receiving fuel as soon as the key was On. If it's not the FPR then consider this: The injectors would only stay open if they had a short to ground on the ECU side. You said that you "get a pulse" with the noid light but what does the light do when the key is on but the engine's not turning? IT should be completely off. Describe the "flooding". Does it fill with fuel if the key is turned on and left on, or only when the engine is running? The first would be a short, the second could be too many ignition pulses or overheating in the ECU. How long does it take to get lots of fuel? Seconds, minutes, or many minutes?

-

WAG - the ECU needs dropping resistors and you don't have them installed. ECU injector transistors overheat and stop working right.

-

Since you've already started it and run it for a while it may be too late, but I would focus on the cam shaft and rocker arms, if they're new. That seems to be the most common problem people have with rebuilt L6's.

-

"Tech" doesn't mean much these days. No offense to any techs out there, but it's just the title that shops give to people that work there. If you can turn a bolt without cross-threading you can probably get a "tech" title. As opposed to a certification or degree in a technical field, like automotive mechanics. Even a certification is only as valuable as the organization that gives it. The factory probably knew what they were doing when they wrote their break-in procedure. Page 27. http://www.xenons130.com/files/ownersmanuals/1982%20280zx%20ownersmanual.pdf

-

An oil pressure switch and a relay would probably do the job.

-

Passenger rear brake seized (1976 280z)

NewZed replied to nacitar's topic in Brakes, Wheels, Suspension and Chassis

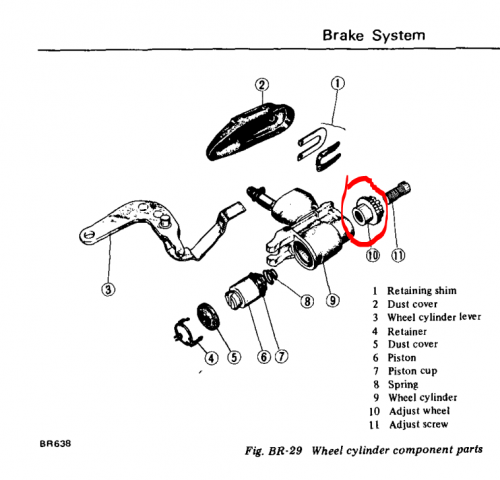

Actually that last instruction isn't much good of the drum doesn't turn. Peel the rubber boot off the backing plate. -

Passenger rear brake seized (1976 280z)

NewZed replied to nacitar's topic in Brakes, Wheels, Suspension and Chassis

-

Passenger rear brake seized (1976 280z)

NewZed replied to nacitar's topic in Brakes, Wheels, Suspension and Chassis

Look at the other half. -

Page 109 in the Rebuild book describes examining lash pad wipe pattern. Not much there except a captioned picture but it's there.

-

Is it Strong Enough?

NewZed replied to nicksoccer22's topic in Brakes, Wheels, Suspension and Chassis

Try to visualize this... then try to answer your question. Can't be done. -

Passenger rear brake seized (1976 280z)

NewZed replied to nacitar's topic in Brakes, Wheels, Suspension and Chassis

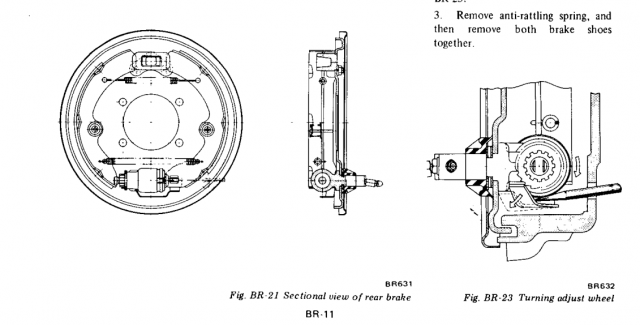

Ya gotta turn this wheel to loosen the shoes and hope they haven't rusted/bonded to the drums. Page 12 and 13 - http://www.nicoclub.com/FSM/280z/1976/BR.pdf -

There's a test procedure in the FSM. Tells where to apply voltage and what to look for after. Pages 19 and 22. http://www.nicoclub.com/FSM/260z/1974/EE%20Engine%20Electrical.pdf

- 2 replies

-

- charging

- alternator

-

(and 3 more)

Tagged with:

-

Interesting stuff, but outside the design principles. The system is under pressure all of the time that way, and the clutch will move toward disengagement as the fluid heats and expands, and away as it cools. Could also be susceptible to losing adjustment over time if one of the seals leaks slightly. Actually, I think that my moving disengagement point is probably due to slight leakage of the primary seal in the MC. Internal slippage. Also, your method makes the fluid in the reservoir irrelevant. It never gets in to the line or the slave. Probably stays nice and clean though. Anyway, sounds like you know what's happening. I'd use a bottomed out slave piston and adjustable slave cylinder rod if I wanted to have the TO bearing pressing on the clutch fingers. It lets the hydraulics do their intended thing and would be more stable in use and over time. Easier to adjust also, and allows maximum throw from the pedal.

-

The hydraulic is self-adjusting, resetting "zero" start point each time the pedal comes up. With the pedal up you can push the slave rod back in to the cylinder by hand, pushing fluid back in to the reservoir. Your adjustments at the pedal would preload a mechanical system though. So you didn't have 6.6 mm of activation at the start, you lost 6.6 mm on the other end, after your pedal adjustment. I assumed (or maybe saw somewhere, can't find it) that Duragg used a mechanical means to preload his clutch. You'd have to have the slave bottomed out and an adjustable rod at the slave and extend it out to preload the fingers. Forgot to say that if you do push the master cylinder rod too far out and piston too far in that you can block the return hole and lock the hydraulics. Then when they heat up they'll push out a little farther. Uncontrolled. It happens in brake cylinders. I've always felt that my clutch is kind of inconsistent in engagement point and wondered if it was the hydraulics. Considering how the seals can blow I'd think that somebody would have designed a mechanical system, for racing or just general simplification. You could probably design a cable pull.

-

I have an engine sitting in the garage with distributor out, all stock parts, probably 150,000 original miles, and I can reach in and grab the tang that drives the distributor with a pair of pliers to give it a twist. I get ~ 1 degree of play if I don't let it move up and down. It has about 1.5 mm of play up and down, and twists about 1.5 degrees on the gear face as it moves. No noticeable bushing/bearing play. Surprisingly tight considering the mileage and condition of the rest of the engine. A point of reference for you.

-

Try the tests here - http://www.pertronix.com/docs/instruction-sheets/1141.pdf The Pertronix modules are an old design without the protective power-cut features of newer electronic modules. If you left the key On for too long you might have overheated it. A stray spark will damage even the newer modules.

-

http://forums.hybridz.org/forum/35-nissan-v6-forum/ Your 85 has a VG30ET. Your 77 is an S30. Your 85 is also a 300ZX, not a 280Z.

-

Air intake temperature SOAR when I step off the gas.

NewZed replied to supernova_6969's topic in S130 Series - 280ZX

Then intercooler only removes heat produced when the turbo pressurizes the system. Otherwise there's no heat to remove, it's at equilibrium. ambient to ambient.. All of your measurements at low or no load (no boost), and with the throttle closed are the same that anybody with an NA engine would see. At zero boost there is no way for the temperature sensor to get hotter than the surrounding metal. The energy just isn't there. It's phyicsally impossible (I left that S there on purpose). So the turbo has little to do with what you're seeing. When you close the throttle but don't disengage the engine from the drivetrain, you might be pulling hot gases from the crankcase in to the intake manifold. There's no air flow to purge them and the pistons are moving faster, compared to idle. One possibility. It might be telling you somersetting about your PCV system, or condition of your rings, but probably has little to do with much. 215 degrees is a pretty weak skyrocket.- 28 replies

-

- air intake turbo temperature

- air intake temperature

- (and 3 more)

-

Open up the PD chapters and take a look - http://www.nicoclub.com/archives/nissan-300zx-factory-service-manuals.html

-

Nearing the end of the rope on my 280z (text heavy)

NewZed replied to SoCal'77's topic in Trouble Shooting / General Engine

Do you have power to the injectors? Have you tried starting with starter fluid? Is the engine flooding with fuel and the wait time is for things to dry out (pull a spark plug and see if it's wet or dry), or is it not starting because it's too dry. You were on the right track, confirming spark and fuel pressure. Now just figure out if the spark is strong enough, and if the injectors are opening when they should. You have to get under the hood with a meter, and a few other tools. -

Amusing. Curse words, watch the sound. short crash at 12:40 but lots of D-baggery along the way. Ends appropriately.

-

how to conect rpm tach on megasquirt help!!

NewZed replied to george k.c's topic in Trouble Shooting / General Engine

Single coil or wasted spark?