NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

Anybody have trouble installing polyurethane bushings?

NewZed replied to jparker893's topic in S30 Series - 240z, 260z, 280z

Compare the new bushing diameter to the old rubber bushing diameter. there's no reason they shouldn't fit., I think that all S30's use the same T/C rods. Make sure also that you read up on urethane bushings and broken T/C rods too. Many people run 1/2 rubber, 1/2 urethane. -

Anybody have trouble installing polyurethane bushings?

NewZed replied to jparker893's topic in S30 Series - 240z, 260z, 280z

Tie rod bushing? What do you mean by "tie rod"? Maybe my memory or general knowledge is off, but I don't recall a tie rod bushing. Post a picture. Edit - just a guess, but maybe you're trying to use the mustache bar bushings in the tension/compression rod spot. They're both big and round. Also note that the T/C rod and its bushings are easiest to replace with the wheels and suspensions weighted. You can reach everything while laying beside the car. Almost impossible to get the bolts back in with the wheel hanging. -

77 280z odd timing, stuttering, hesitation on throttle

NewZed replied to ISPKI's topic in Trouble Shooting / General Engine

Google is full of "280Z firing order" posts and images. Probably easier to look at too, than the attached picture. -

Wanted 280 Z left rear tail lens surround plastic garnish

NewZed replied to zentech's topic in Parts Wanted

Do you have one Tokico shock - HZ3102, 3013, 3015, 3016 or 3038? I have the part, need one shock to fill a set. No gland nut necessary, just the shock, still pressurized and no signs of internal damage. Used is fine. -

1983 280zx will not idle, bad hesitation

NewZed replied to dukemushroom918's topic in Trouble Shooting / General Engine

What, in numbers, is the timing set to, initial, and what does it do when you rev the engine? That will tell you a ton about your timing and distributor quality, more than the finger test of spring tension. After it starts do you move the timing back or do you leave it at maximum advance (whatever that is)? What, exactly, non-essential components did you remove? When you talk about revving, is this while driving, or in neutral? What does "hesitation" mean, if you're in neutral? Odds are high that you have a vacuum leak and something out of adjustment. -

They got me. Apparently, there is actually a pump that pressurizes the tank. so weird that I didn't even search first. No wonder cars aren't getting lighter. I think I'll avoid all cars post-1995. http://www.autozone.com/autozone/repairinfo/repairguide/repairGuideContent.jsp?pageId=0996b43f802d818d Edit - although, it doesn't appear the the GMC Sierra uses one. So they were almost right.

-

Saw this column this morning and thought it looked like BS. Maybe the original Click and Clack have sold their identities or the whole thing is just a show. MIT graduates? The implication is that there's a pump that pressurizes the fuel tank, It would have to be an air pump that pumps outside air in to the tank. Sounds like total nonsense. http://blog.nwautos.com/2014/05/randomly_running_truck_is_confusing_owner.html?prmid=obnetwork

-

Drivetrain 'slop' Question for Turbo Car

NewZed replied to BlackdogNY's topic in Ford V8Z Tech Board

Looks like you're thinking abut buying this car so don't know much about how it was put together. What does the builder say about these issues? Could be something as simple as weak motor and/or transmission mounts. Sounds like a poor job on the swap. Something is loose or mis-aligned or out of balance. Stuttering (shaking?) on deceleration is a sign, since it has nothing to do with peak horsepower. Forgot to say - this isn't a Ford issue, it's more of a general drivetrain or swap issue. You might repost in a different forum to get more looks. -

1976 hard time idling after AC and heater removal

NewZed replied to dpuma8's topic in Trouble Shooting / General Engine

By "idle screw" do you mean the idle air screw, or the idle speed screw? If you added more AFM bypass air that would lean out the mixture. If you just added speed, that won't affect the mixture much. Not clear how warm the engine gets while you're testing. Could be that you switched the coolant sensor plug with the thermotime switch plug. Or the coolant sensor has lost connection. Maybe it's really just very rich, and there is no vacuum leak. Pull one of the small hoses from the intake manifold and see if idle speed goes up or down. If it's already lean from a leak it would probably go down, if it's rich it will probably go up. -

Trolling three week old posts to give advice you're not sure about seems a little odd. Post count pumper?

-

rb25det with rb20det tranny. speedo wont work need help !!!

NewZed replied to rb25detSpoolin's topic in Nissan RB Forum

The speedometer determines what type of speedometer drive you need. You need to describe your speedometer. If it's a stock speedometer, people could probably figure it out if they knew what kind of car you're working with. Engines don't require speedometers. -

Did you swap the MAP sensor to try and fix the problem or was everything fine until you swapped the sensor?

-

Iron/Aluminum block external casting differences.

NewZed replied to MaxxAction's topic in Gen III & IV Chevy V8Z Tech Board

Web page implies it's been tried and tested. http://www.lojinnovations.com/z32%20kit.htm -

switch2zcar.com down, need z31 wire diagrams for l28et

NewZed replied to subtle_driver's topic in Nissan L6 Forum

Might be something useful here - http://forums.hybridz.org/forum/92-turbosupercharger/ -

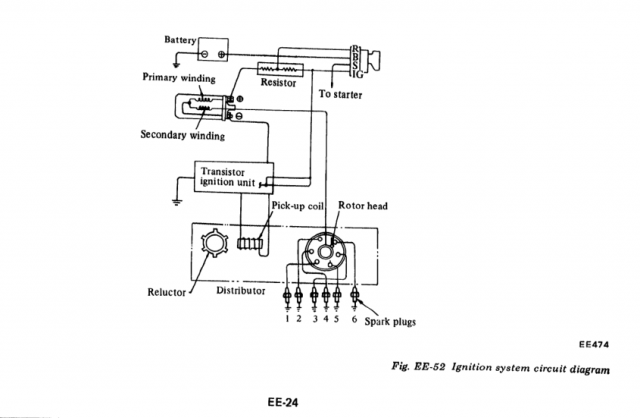

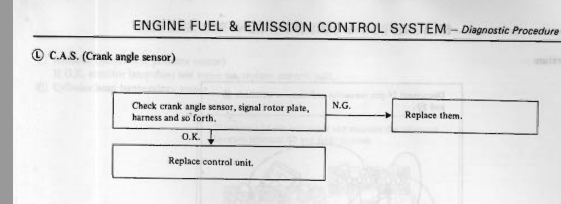

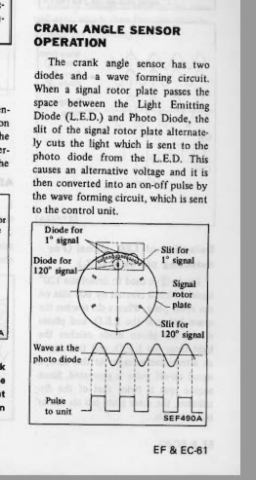

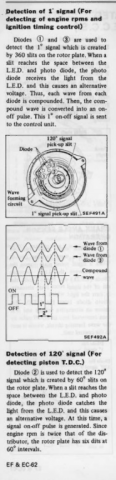

I can't really follow what your expectations are but the attached pictures might help show what the CAS output should be. Two of the wires should show a voltage pulse, from zero to probably ~5 volts. One of the wires will pulse rapidly as you turn the distributor because it's seeing 360 slits per revolution, the other will sit at zero, I believe, and only change state six times per revolution. So, if it were me, I might fabricate a narrow blade-shaped probe that I could slip in beside each wire in the connector while it's plugged in, to measure voltage. With the key on and no CAS movement, you'll probably get a 5 (that's your power supply to the CAS from the ECU), and maybe a 5, and a dead one. Stick the probe in the two that aren't constant 5, and spin. I might be way off, but that seems to what the pictures and text say. Added the "And so forth" picture just for the humor.

-

77 280z odd timing, stuttering, hesitation on throttle

NewZed replied to ISPKI's topic in Trouble Shooting / General Engine

Going from 15 to 25 is advancing the timing, not retarding. The obvious next step is to confirm that your pulley timing mark is correct. The notch needs to align with zero at top dead center on cylinder #1. Have you adjusted the valves? If you're not filling the cylinders fully (too much valve lash), then advanced timing would probably help. Have you confirmed that valve timing is correct (groove and notch on the timing sprocket and retainer)?. Incorrect valve timing could have a similar effect. Piece-meal is going to take you forever to get that engine running right but at least you're making progress. -

Mercedes OM606 swap with a manual transmission

NewZed replied to gijohnny23's topic in Other Engines

Post the youtube video link. Post the link "on here" about the 300zxtt transmission on the Mercedes motor. There. -

The Porsche bumper rubber looks good. Don't park where anyone can park behind you though, many people take "bumper" literally and use them as distance measuring aids when parallel parking.

-

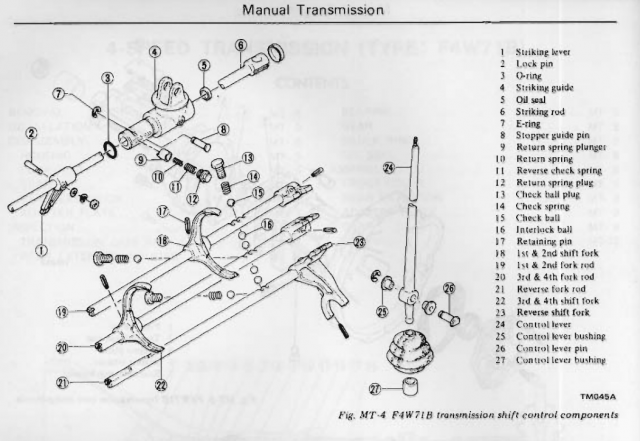

There are so many people out there these days staring at the internet on their tiny phone screens, I just assumed... Rebuilding "while you're at it" could be false economy, the rebuild kits out there aren't fantastic and some seem to have worse new synchros than used Nissan synchros. If it was in good shape you might just replace the main and counter bearings, while you're in there, fix the fork, and put it back together. Just an opinion. You can replace a fork without pulling any gears. Search Hybridz member duragg for a long thread on modifying the transmission for high RPM duty. Lots of detail in that thread.

-

Are you on a phone? There's a picture in Post #2. Pretty self-explanatory.

-

Here's one. I know nothing about the company, the guy, or the cat. http://www.brokenkitty.com/ http://www.brokenkitty.com/zcar/zcar.htm

-

grounding locations for ecu.

NewZed replied to wickiewicked240z's topic in Trouble Shooting / General Engine

Will it stay running? Idle? You can swap injector plugs to see if you have a wiring problem or an injector problem. Take the injector plugs off, one at a time, and note which cylinders work and which don't. Then swap a plug from a cylinder that works to one that doesn't and see if the dead cylinder comes to life. It won't fix things but it will tell you a little more about what's going on. And check your plug wires for firing order. 153624 counterclockwise. -

This is normal.

-

gland nut welded to strut tube

NewZed replied to grillhands's topic in Brakes, Wheels, Suspension and Chassis

Tack welds to keep it from spinning, or completely around? You'll understand the gland nut's purpose after you grind the welds to free the nut. BUT, you may actually be looking at the welds that hold the gland nut together itself. Aftermarket nuts typically have a flat hexagonal plate, for wrenching, welded on to a threaded core. Post a picture before you tear things up.