NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

MS3 w/ MS3X Install - L6 turbo, sequential injection & boost control

NewZed replied to Sam280Z's topic in MegaSquirt

Wouldn't duty cycle give you a ball park figure on size? Kind of irrelevant for these injectors since they're hard to find but still might be useful in general. -

Nightmare Fairlady 280z fuel problems

NewZed replied to Nightmare_Fairlady's topic in S30 Series - 240z, 260z, 280z

Check continuity of the wire from Pin #1 of the ECU harness to the negative post of the coil. That's what triggers the ECU to open the injectors. -

Start a new thread in the proper forum instead of tagging on to an old dead thread about a BMW engine swap. In the new thread, describe exactly what you did that lets you know the fuel pump "dosent suck up fuel". Good luck.

-

Move your thread to this forum - http://forums.hybridz.org/forum/35-nissan-v6-forum/ , read the threads on the other VG30 flavors, and be more specific than vague terms like "retained equipment". What does that even mean?

-

Fuel pumps will run backward. Check the wires. And the obvious, considering Metor's post - pull the hose from before the fuel filter, not after, and see if any fuel flows. Put some thought in to how things are supposed to work. What now, what now, what now will take you forever. Getting fuel to the fuel rail is probably the simplest of the problems ahead of you.

-

An internet search on Datsun Parts LLC would have thrown up some flags. Yours is the clearest case of bad product that I've seen described though, besides the sand in the cylinder head story (see below). I'm sure that many people are just too embarrassed to share their experiences. A warranty for normal use is one thing, mis-representation is another. You might take your engine to someone who knows the engines and see if you have a case for a lawsuit, or PayPal or credit card claim. If it's worth your time. You'd be doing the rest of the world a favor. Here's a fairly recent thread on this guy - http://forums.hybridz.org/topic/105897-l28s-from-datsun-parts-ebay-store/ I hope this doesn't ruin your holidays. You might actually have some good parts there. My impression is that the guy buys used parts individually and reassembles them in to packages. Who knows, he might mean well, just doesn't know what he's doing.

-

"123 Ignition" Distributor Replacement for Nissan L4/L6

NewZed replied to Tony D's topic in Nissan L6 Forum

If the focus is on tunable advance curves, wouldn't it be simpler to use an external box? Miniaturizing is difficult, and could be the show-stopper. Once you get the basic hardware and the code worked out, that could come later. You could even strap it to the side like a ZX module instead of under the cap.- 30 replies

-

- Programmable Ignition

- Megasquirt

-

(and 3 more)

Tagged with:

-

Did you build the engine originally with these performance mods, or did you buy it this way? You said it was rebuilt but didn't say who put the packge together. If you bought it then confirmng what you have is a good idea. Confirm that zero on the damper pulley is actually TDC, cylinder pressure is not too high (if the heads been shaved CR could be higher than calculated), advance mechanisms work right (a spring could have popped off of the centrifugal mechanism), cam timing is correct (does Schneider provide a mark for reference or do you have to use a degree wheel?), etc., stuff like that. Considering what you said about the way you received the engine it seems reasonable to assume that somehting else might be screwed up too. Make sure that what you think is detonation is actually detonation, if you can. Maybe detuning the engine with retarded timing is just covering up an exhaust leak or some other noise that sounds like detonation.

-

BWD from OReilly Auto Parts.

-

I check mine with the wheels on the ground. Grab the top of the wheel and shake back and forth. Clicking noises from the hub area are a sign. But you could get misled by other parts moving around, like brake parts. You could also go by the FSM procedure and retorque the nuts, then check rotational drag. Just retorquing the nuts might tighten things up to where you know it was an issue, or just checking tightness of the nuts. Loose is bad. If you have to ask though, you might want to get some help. I hadn't been working on cars for quite a few years when I got mine and it took me a while to get my mechanical "touch" back.

-

I burned through my first set of new tires way too fast trying to use toe to correct for worn wheel bearings. If you're on a well-travelled road it wil have ruts, and the wheels will try to follow the ruts. Worn bearings let the toe adjustment change as you're driving. Most shops check for looseness but some just know how to put the car on the rack and run the machine.

-

Two problems were described - one, it won't pull past 5500 RPM, and two, it suffers detonation if the timing is advanced toward a "normal" range. Those two things aren't necessarily related. The power peak below 5500 RPM is pretty typical for the stock 280Z L28. Usually the cam is pointed to as the cause. Maybe your Schneider cam just isn't designed to breathe at high RPM. I assume that the restrictions of the intake ports and manifold play a part also. Whatever it is, the behavior sounds about like my factory stock 280Z L28. On the detonation issue - cylinder pressure will give a good idea of how the compression ratio (CR) and the cam profile, and its timing, are working together. High CR will raise "static" cylinder pressure, and the valve timing of a performance cam grind is supposed to lower it. Cylinder pressure, not compression ratio. Measure cylinder pressure and see what you get. Over 200 psi seems to get people closer to detonation problems. 170-180 psi is common for a stock engine.

-

Go ahead. Describe what manual you were using also for anyone else that's using it.

- 5 replies

-

- Fuel injector

- DIY

-

(and 7 more)

Tagged with:

-

Nightmare Fairlady 280z fuel problems

NewZed replied to Nightmare_Fairlady's topic in S30 Series - 240z, 260z, 280z

Good luck. Looks like a wild goose chase though (they're faster than they look). You've switched directions entirely from fuel pump doesn't run to injectors don't inject. Did the mechanic turn the engine over and look for flashes or just plug his device in and wait for something to happen? Putting a bunch of new stuff on when you don't know what's bad is a great way to make the puzzle more complicated. At least the relay might be a good investment, for resale. New ones go for over a hundred dollars. -

DOHC L6, Was somebody looking for the Goerz-Paeco DOHC L6 Head ?

NewZed replied to Vintageracecar's topic in Nissan L6 Forum

Will this item be worth more or less after doing the work to actually use it? Probably worth more with dream still attached. -

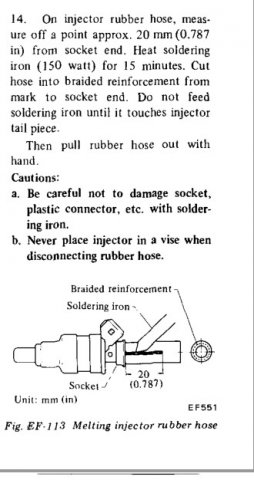

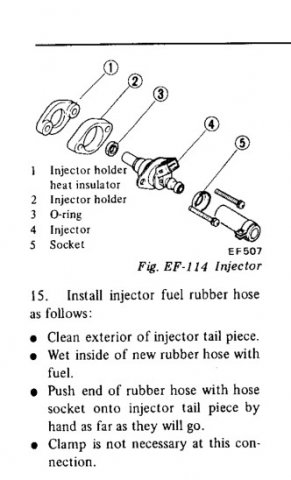

Interesting writeup, and a good start to getting these old cars working right. You were a little bit too innovative in the hose removal though. Attached are a couple of pictures of the factory procedure. Most people simplify even more and are just very careful with a razor blade or Exacto knife, and clean up any nicks afterward. And, with the right hose (good quality 5/16" EFI-rated hose) and the socket (or ferrule, the ones that you ground off) no hose clamps are needed. The barbs will do the job. The pictures are from the Engine Fuel chapter. Worth reading end-to-end, even just for fun.

- 5 replies

-

- Fuel injector

- DIY

-

(and 7 more)

Tagged with:

-

Is it connected to your throttle linkage? Might be cruise control.

-

turbo swap ecu wiring difficulties,please help.

NewZed replied to Turbo72-240's topic in Ignition and Electrical

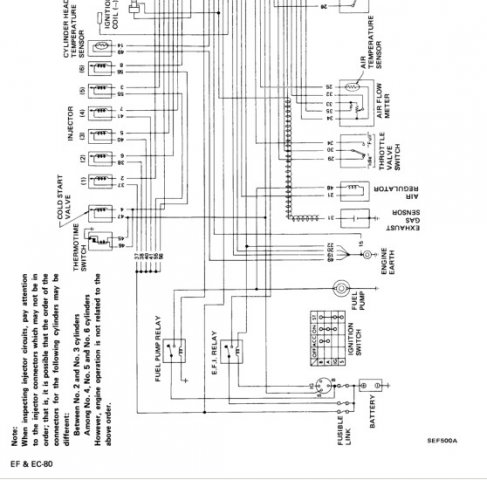

Power to both sides is normal, it's one of the weird things about transistors. The ECCS from the turbo cars uses the CAS to determine when to spark and inject so you have a mystery since you have one but not the other (you are using the CAS right?). If I had your problem I would start reading from EF&EC - 64. The later FSM's aren't as instructive about the principles behind the engine management, they lean more toward testing and replacing parts. More dumbed down than the 280Z FSM's. They still have some good wiring harness diagrams in them though. There are some smart guys on the forum who've had lots of experience with the turbo EMS. You might have to put more effort in to puctuating and formatting your posts though to get a response from them. Good luck. -

They're connected anyway. Moot.

-

If it was a short at/in the starter it would turn as long as the big cable from the battery positive was connected. Since yours only turns when the key is on you just have something providing power to the small wire (probably yellow) to the starter solenoid. It's a wiring problem. Wire colors are shown in the factory wiring diagrams. It's not as hard as it seems once you dig in. Start at the starter and work backward until you find out where the power is coming from.

-

I ran a 76 intake and exhaust on a 78 round port head for a couple of years. Shouldn't matter. The exhaust manifold can be an issue but only if you use the round port exhaust on a square port head. It blocks the edges of the ports. But you don't have that problem. If you go through my list you might find something. I've the same problem when I forgot to reconnect the AAR power. Without power to the internal heating element it takes a long time to heat up and close. And the connector is jammed up against the hose so it can look connected when it's really not. Actually, I've had high idle problems from five of the things on that list.

-

Thought this was about the RB26DETT in your sig. If you're using the stock 280Z throttle body and intake, there are many possibilities, from sticking throttle blade to hanging throttle return dash pot to bad BCDD diaphragm to stuck AAR to no power to the AAR (although it would only hold the idle up until the coolant got warm) to cracked PCV hose (including the one from the valve cover) to no dip stick in the dip stick tube, and more. If you're using the stock 77 ECU, there are no sensors that control idle directly. Don't forget that advanced timing will speed idle. 77 had a solenoid valve, controlled by a switch on the transmission, that only let vacuum to the distributor advance when in top gear. If you connected the hoses wrong you might have more advance than planned and a faster idle.

-

Spooner...

-

-

Page 80. Last clue before 10!!!