Leaderboard

Popular Content

Showing content with the highest reputation since 01/04/26 in Posts

-

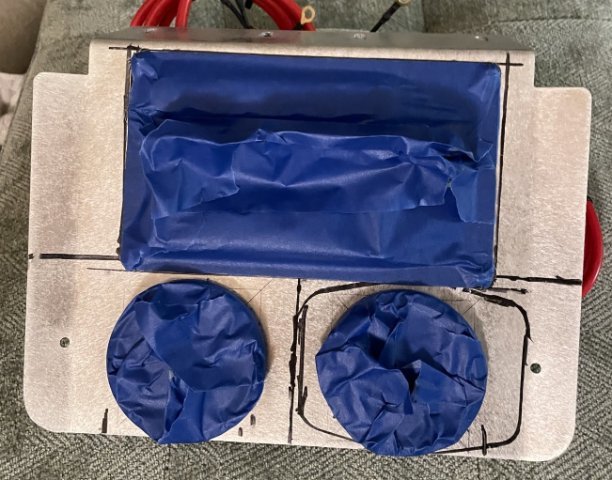

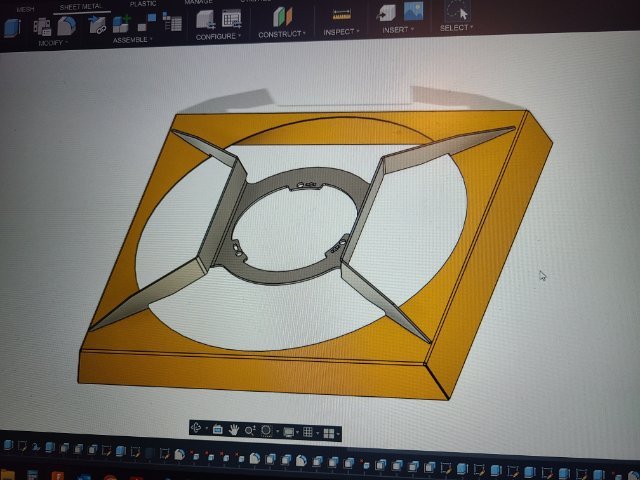

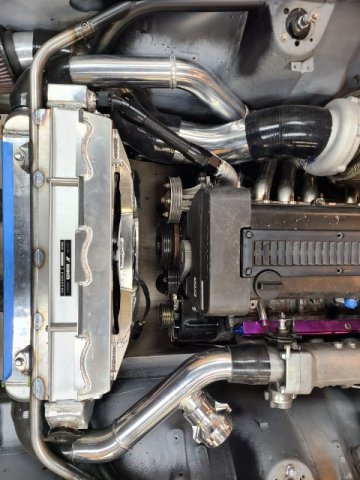

Next order of business was electric fan and shroud, and radiator hoses. I chose the 2016-2019 Camaro single SPAL 18" fan. it will be PWM controlled and is a very popular choice according to the internet as it can flow 5000CFM. Although I cut up the factory shroud to "work" I felt like I needed something fancier. modeled up a base to start working from and had my friends at laserbros in NC laser cut and bend it up. Should have gone one or two AWG thicker so added some bracing as well as some mounts and very happy with the final product. Cut down the radiator and inlets and outlets on the engine and welded on some -16an bungs, made up a couple hoses. in the last photo of the "hose installed" you can see the end of the pipe for the intake I welded into the chassis I mentioned in the previous post. Also decided to move the alternator to the other side of the engine to get it away from the heat. When i pull the engine to paint the bay i'll design and make a bracket to permanently mount it over there.4 points

-

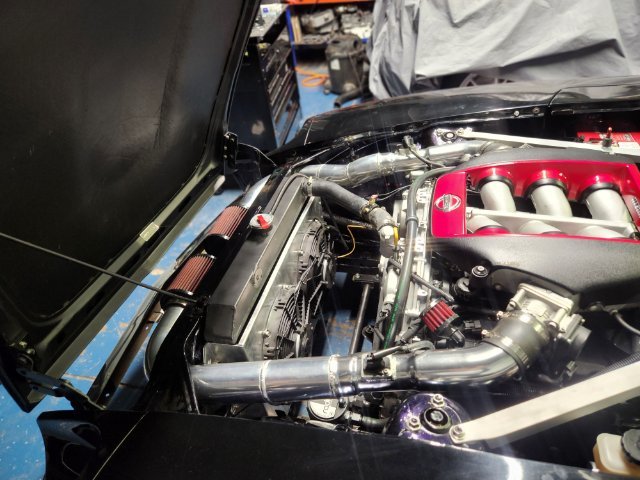

Hi everyone, I am at a good point with my build and wanted to share its history since its one of the few running and driving VQ37 swapped Zs in the country. I am going on over a decade of ownership. I originally bought the car from New Mexico and brought it over to Colorado. Come to find out, it was once a Colorado car also. I picked it up in primer with a rebuilt engine but not really knowing too much about it since all I had were photos and the owners word. The previous owner used it for autocross. The entire interior was missing and it had a rats nest for wiring. I remember it had a switch to manually turn on the fans. It also had a full radiator support and driver side frame rail replacement from a donor Z. I got lucky that this was done really well, I have had no problems getting the car aligned over the years and it drives straight! I saved some money and got the car painted in black, the car was originally a yellow car. The painter actually welded in floor boards and frame rails and closed up the wheel wells from where they were cut for the ZG flares. The rear hatch had to get replaced since it had an inch of bondo over the key hole. Luckily, I was able to track a hatch from a 240Z in the junk yard (when is the last time you have seen that haha). I added sound deadner to the interior and then took the car to an upholstery shop to get the interior put it. I also added some nice gauges. I was able to source some cheap Watanabe 16 inch wheels from yahoo auction Japan. They were different colors but I ended up paying around 900 usd after air shipping them spent another 300 getting them powder coated. I also picked up my Recaro seats from Japan. To this day I have no idea what car they came from but they are one of my favorite parts of the car. The SUs where swapped out for a triple Mikuni 44s. I drove with those and even had them tuned but they were too finnicky at altitude. During this time I got into flipping carbs for resale. I didn't want to deal with the Mikunis and decided to swap to fuel injection. I ended going Jenvey ITBs on Haltech. This setup actually worked great for about a year and even made it to the main page of my local Cars and Coffee. Around that summer I started to develop some running problems where I was running too rich. On my way to the tuner the worst thing happened. The car caught fire. From what I could tell, the itbs backfired and caught the fuel line on fire. If anyone is running itbs on an L Series, I highly recommend an airbox. I got really lucky since a guy like 2 cars back behind me had a fire extinguisher and that the radiator hose blew and stopped the fire. I sent the car over to my tuner/builder and waited on my insurance adjuster to visit the car. I was able to get a full payout through Hagerty and that kickstarted the funds to get my Z back on the road again. I knew I was done with L series. I never really wanted to build something that close to race car since I mostly drive my Z on the streets and occasional canyons. I wanted to stick something Nissan that could remain relatively stock. Something I could start up and just drive. In the past I almost swapped VQ35HR motor and have always had that build in the back on my mind but I noticed that the engines were almost the same price as the bigger brother VQ37. So I went with a VQ37 out of an automatic AWD G37. The reason I chose that engine was to avoid 370z's had been driven hard and the auto engines were cheaper with less mileage. The only change to the block that I needed was a lower oil pan from a RWD VQ and its bolts. I sourced a transmission directly from Nissan since at that time it was actually only about 500 dollars more compared to a used transmission. I looked recently and it seems like the transmission have doubled in price since 2021 when I bought mine. Here are the photos of when I got her back. We ended up putting some flake in the engine bay since I grew up loving lowriders. I also installed a GTR intake conversion. It ended up being a bit of a hassle since the custom fuel rail didn't clear the injectors. We had to extend the fuel ports on the fuel rail to make them taller so that it could clear. I added a catch can since the car is set to vent to atmosphere. I pulled the headers and stripped them and cerakoted them also. The custom hood didn't make it out of the fire so I went carbon fiber. Next I ended up getting the intakes extended to the front of the car to make it a true cold air intake. I recently took the Z engine harness apart and reloomed it and fixed one of my turn signals. Come to find out one of the wires was cut off. With the help of Dave Irwin, I was able to track down all of my missing grounds and also why both lights would blink at the same time (bad switch). I had an extra parts turn signal switch which I harvested and was able to get everything to work out. I recently tackled getting my horn to work. I have never got it to work since my entire ownership. The guys at classiczcar forum really helped me trouble shoot it. Come to find out, my only horn didn't work and for some reason my steering rack wasn't grounded. This is pretty much where the car is now. I took her to a local car meet today and I am hoping to just get more seat time with her. If anyone has any questions about the car or the swap feel free to message me.3 points

-

Got the rear calipers on today. A few challenges getting this to fit for the 240Z. Tight tolerances between rotor and caliper, needed some washers to align it right. Also getting the pad clips on were tough, some clearance issues with the wheel well as the pins go in from the back, but got it eventually. I love big brakes 😍.2 points

-

A new year has started and my battle to get the 280z road worthy goes on. I had liked to get some more things done over the holidays but sickness and other obligations got the better of me. That doesn’t mean I didn’t get some progress in. To prepare for a new years eve party I had to temporarily get the Z inside the garage so I continued my journey of stripping down the Z by removing the fenders and wiper cowl. I kind of regret but I'm also glad I did. Turns out the last “restauration” was a fairly cheap one. Some threads where damaged and instead of repairing the thread or welding in a nut they just left the bolts out, or in case of the lower mounting points of the fenders just weld and bondo them on. After getting them off I was met with the nice surprise of finding out they never painted the inside/back of the fenders or any non-exterior part for that matter, only primer. As a result I was met with a lot of surface corrosion spots. I also discovered the car has some crash damage on the front left that was never properly repaired. Some sanding, rust treatment and painting later the car already looked a lot better. At least now I know the Z won’t rust away in the next couple of years. Every panel I remove it becomes more and more clear that a full restauration to the bare metal of the body is necessary if I want this Z to survive at least another 10 to 20 years. I really wanted to start installing some of my new goodies from Apex so I decided to install the rear strut brace as it won’t interfere with any of the bodywork. It was freezing outside but with the help of a heater it was quit doable. I do love the look of the Apex rear strut brace. It’s strong, elegant, functional but doesn’t scream “aftermarket modification” which I like a lot. I don’t really want my car to stay stock but also not heavily modified, just tasteful, functional and a bit more modernized but still the classic look and feel. The last few couple of days have been pretty cold so I moved back to the garage for some of the car work. Unfortunately my garage isn’t insolated and I don’t have a strong enough heater but it’s better then outside and good enough for some paint work and rebuilding the hinges. Rebuilding the hinges was easier then I though at first. Having a vice does make life a lot easier when removing and installing the hinge pins. To get them out I just used an impact socket and an old bolt that was slightly smaller then the hinge pin. With some force they came right out. All hinge pins where worn which caused the doors to sag and the passenger side (which sagged the most) was even bent! The rebuild kit I bought from Zservices EU was great with the exception of the hinge pin bushings, both the outer and inner tolerance was out of spec on all of them. If it was to tight then that wouldn’t be that much of a problem as I could modify them but the tolerance was to loose causing the bushings to sit loosely in the hinge and the pin to have some play. I decided to rebuild the passenger side hinges anyway and will install them soon to see if they sag with these bushings installed. If they do I will have some custom made at a machine shop. Continuing with the doors I decided to do some spot repair on the upper corners of the doors as both sides had some corrosion under the paint, and the doors where off the car anyway so might as well do them now. Here to I discovered the inside of the door was never painted causing some corrosion on the inside of the doors. The more I work on the car the more I want to punch the previous owner and bodyshop in the face. Even so I can't wait to drive the Z, I guess that’s the S30 life for yea….2 points

-

For you that have been following along. My 3.12L is finally in my car and home. Gosh it looks so good I’m just going to stare at it! Amazing work by Andrew Kazanis! This engine was built and done prior to a shop fire. So it’s been through a lot! I love the contrast of the stock blue block and gold zinc and black. It features. My 3.1L 10.2:1 compression ratio 88.5mm bore. N42 block. Sonic tested. LD crank by marine crankshaft. Crank �Off-set grind to 84.6 stroke�Finish rod journals @ 1.8889" Thrust Finish 1.27”�R & R plugs with threaded plugs�Dynamic Balance�Ion-Plasma nitride, straighten & micro-Micro polish all journals E31 head. Port work by Andrew Kazanis Dsi valves Diameter: 45/36.5mm Length: 118mm, titanium retainers. Isky springs. Bonk cam. Roughly stock exhaust and intake port sizes. Vapor honed inside and out. Rebello JE Eagle pistons and toyota rods 221 CFM flow at .45-.5 lift. Mine is 88.5x88.5x.25x3.14159x 84.6x6 /1000 = 3122cc It is showing off my intake design and Efi throttle bodies as well as a bunch of my small parts.2 points

-

Hey Derek. Good to hear from ya. Yeah input a vfd on it. And it already has the variable speed feed. It also has the indexable cutters on the head. Which will be fine to start but im looking at switching over to a single pcd/cbn cutter. I might have to do a pulley change to get the sfm where it needs to be. But currently im waiting on a box to put the vfd and other electrical components in. Im putting it on the machine where the motor start switch ans box was.2 points

-

1 point

-

I sat in those tillet seats at PRI this year and was very impressed with the hold and comfort despite not looking like it would be either.1 point

-

1 point

-

The reason for this video is demonstrate the Quality of Car Bodies that are produced by a Chinese Manufacturer who also produces the 240Z assembled body. The Actual Chinese Reproduction of Toyota A86 Body was purchased and examined by several individuals who expressed their opinions about the body. The owner will attempt to assemble the vehicle with available Aftermarket Parts( tail lights, interior parts,etc. This body was the same one at the SEMA Show so time will tell its quality and parts fitment is up to the OEM Standards. This body came from the same factory as the 240Z body at the Sema Show. I checked this at the Sema Show and after watching this video, my opinion on this car is there is a definite lack of quality control in the welding of this car. There seems to be a lack of spot welds on some of the panels. On Utilized Body Cars, spot welds will determine the strength of structure. Normally, the original manufacturer would use Robotic Spot Welders on the Assembly Line. On this car, the welds are not located close together thus not providing a strong panel. Another major flaw is the Front Strut Mounting Holes are oval not round as they should be. This shows a definite Quality Control Issue. It seems that assembly of this car was rushed and put together just for the show. The Collision Industry has a established Standard -ICAR which provides proper methods of assembly of Body Parts. A ICAR Body Specialist should inspect this car before it is put on the road or used as a race car.1 point

-

1 point

-

Thanks for bumping this thread, good read and some good resources for me to follow up on. I will be getting to the aero parts of my build soon and this already has given me some new ideas. Balance is definitely the big thing that can be missed and tire sizing comes into play here too which I’ve already been thinking about. Most likely going with a wide square set up for the track, so increasing oversteer with just tire set up.1 point

-

1 point

-

FYI -- I've confirmed with SuperDan that the site certificates have indeed been updated. Some users may need to refresh their browsers to update the cache or empty the browser cache. Cheers.1 point

-

This matches my experience too - a lot of aero “common knowledge” starts to fall apart once you actually try to measure things. The front-vs-rear balance point really stood out to me; I always assumed any lift was bad, full stop. Makes me rethink how careful you have to be adding splitters or diffusers without addressing the whole car.1 point

-

01-20-2026. Engine wiring harness. So, today I took my custom Lime-swap wiring harness for the ATLAS, and stripped off the looms and tape, so I tailor can fit everything and cut the wires down for a good, hidden fit. it's quite a bit of work removing the plastic bracket that originally held it on to the valve cover, straightening it all out, getting it all ready to be installed and then separated and cut and spliced back together correctly. I have these special splices they advertise that melt with a heat gun and solder the center.....I thought I'd try them. Some exposed wiring parts will have the chrome looms I bought over the wires, as you can see in the Injector wiring in the separate pic.1 point

-

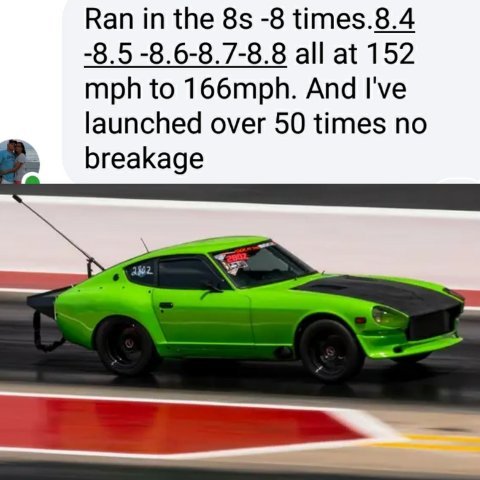

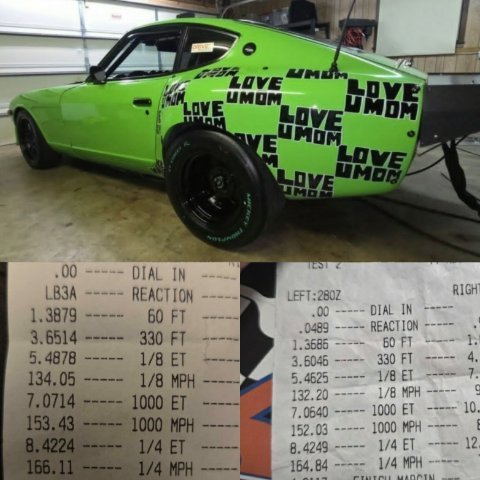

Unless somebody has a faster timeslip, fastest IRS s30 (barely) so far is Terry Garmon with 8.42 @ 166 mph in the 1/4 mile. Also included is a picture of Rick dunns 700hp car with the newest version of the rear swap, and a picture of all the components laid out, including the axles. The setup has evolved over the years, but even the earliest versions are out there putting down thousands of miles with all kinds of high and medium hp levels.1 point

-

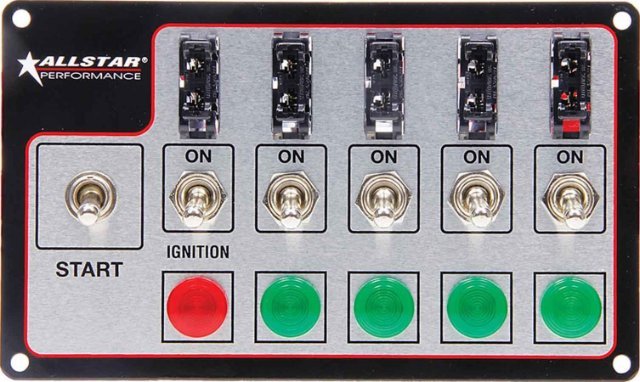

Another pic of the toggle cluster I am putting in my Atlas Z. fused and the start toggle is a momentary switch. when you flip the ignition toggle it will kill all power to the stand alone engine harness that the fuel pump runs through. I love the old school look. The quality of these toggles when you operate them you don't see often these days anymore....I got it at Summit and yep, the price is high, but the quality is A+.1 point

-

01-19-2026 First survey of my customized stand along wiring harness for the GM Vortec 4200 / ATLAS 4.2 engine swap. Keep in mind If I had kept the auto trans there would be more....I also deleted 90% of engine functions as well....only kept the cool stuff like gauge feeds, etc. At least I have a wireless throttle! enjoy the video. 01-19-2026 harness video.MOV1 point

-

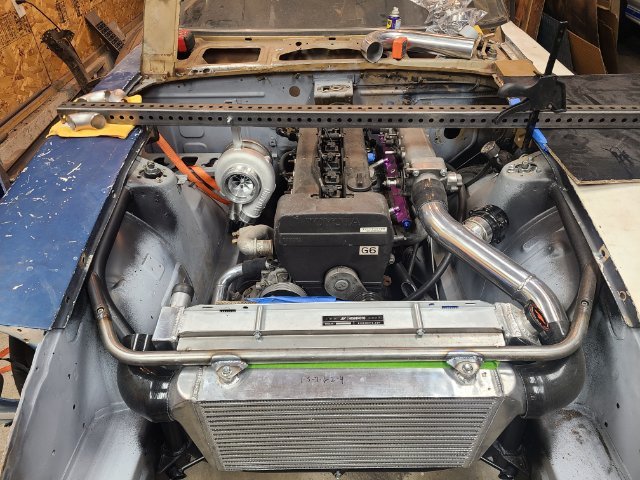

started tackling the turbo system. designed and machined a stainless exhaust flange because I couldn't find one I liked. 304ss that seamlessly transitions the oval port to round so i can use sch 10 stainless. Went with a billet turbo flange from elmer racing. I make these kind of things but no way I could have made one for what they charge. beautiful piece. I ordered 321 sch10 stainless weld els to make the rest. after a little "writers block" i finally got a decent layout for a turbo manifold. The car came with a precision turbo but unknowing the condition and the size wasn't ideal i ended up going with a garrett gtx3076r with a v band inlet.1 point

-

Very interested to see. Jim's Swiss 240Z (stock internals except for a mild cam) with ITB's and a Holley ECU tuned by our local legend - Tony at UMS - made about 183 RWHP. Jim was a bit disappointed (he was thinking 200ish) but we all thought that was pretty amazing for just ITB's and a good tune! It would be nice to see what all your engine work will accomplish. In ANY case it'll be a blast to drive!1 point

-

1 point

-

1 point

-

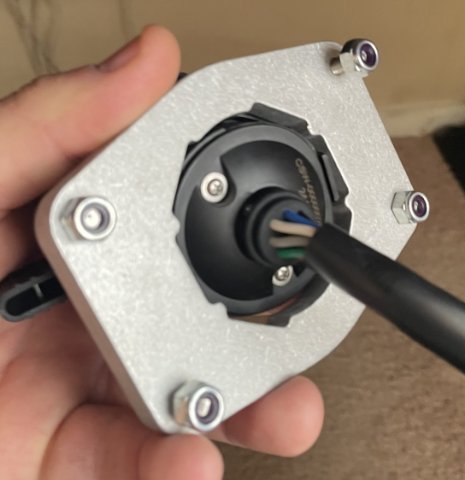

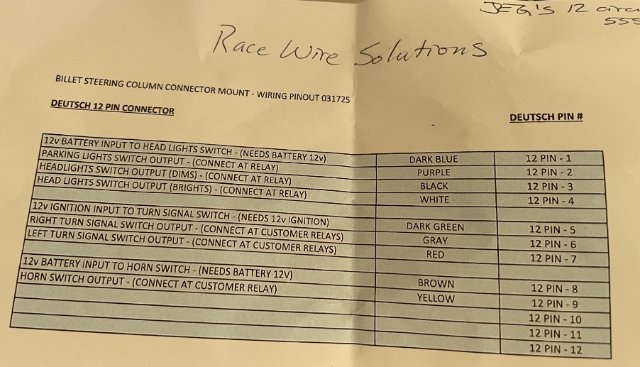

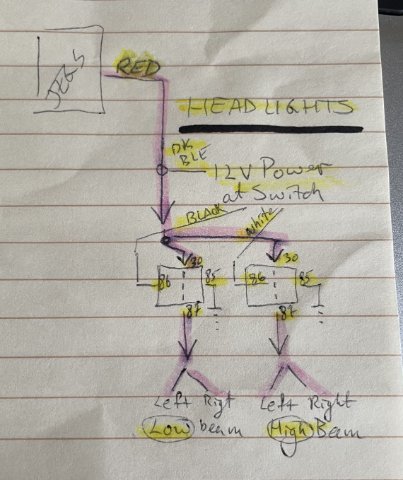

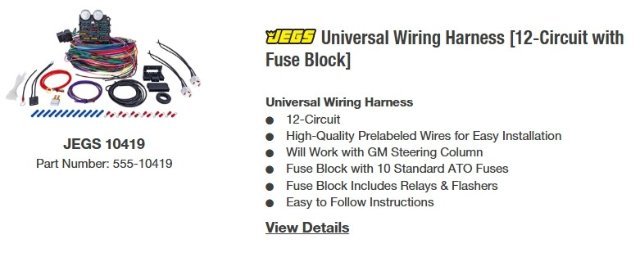

01-11-2025. Pretty cold out today, so I stayed inside and started looking into some of my wiring questions I needed to solve. My combo switch and adapter plate from Race Wire solutions came in the other day, and I will be using that along with the 12 circuit rewiring kit I bought some time back from JEG's. I got Chat GPT to help me keep it straight in my mind and went about figuring out how to wire in my combo switch with what JEG'S sold me. it will be installed in the dash, as part of the dash center plate I got form Skillard, along with 2 gauges and a cool panel/bank of switches made by Allstar Performance I ordered from Summit. now to decide paint the4 panel or upholster.....1 point

-

Looks nice, Im guessing 260hp at 6500 to 7000k Do you plan on dyno testing it? Seems like it will be a super fun street car. Realy clean but not so over the top that you cant drive it everyday and enjoy it. Looking forward to more.1 point

-

There was a guy in Socal i went to visit 20 years ago that built cars like this. He did work for Toyota making them an all aluminum GT2000 and working on Shelbys 2nd gen cobras. This is pretty impressive. I hope they make a Z one day.1 point

-

Well look at you! I have a SV 85B for doing my heads. It'a a were one with variable speed feed drive. The best thing I did was to put a VFD on the spindle. I over clock it at 120hz and it does just fine.1 point

-

1 point

-

There was chatter at one point about the welds on CX racing stuff being a concern (particularly the exhaust turbo header).....so you will want to check the welds carefully prior to putting everything together. Front and rear strut tower braces, a roll bar, Apex front side structure supports, and maybe stiffen up the rails .......bad dog used to make thick steel rails that fit right over the originals and then have them welded on. 500 horsepower is an incredible amount of power in a Z car. 300 horsepower in a 280Z is a windowmaker. Good luck!1 point

-

Sorry for the delayed reply. Was having difficulty with my Password and trouble posting. Thanks Administration for correcting problem. Disc brake and Hand Brake Installation- First, Important Notice-The Invinclble Extreme 8.8 Differential Conversion Kit requires the use of 2015 to 2024 Mustang GT Rear Disc Brake system. All related Suspension Parts were created to work with these parts. Check carefully if any alternate brake parts are used for fit and function. Otherwise, Different Parts may require Modification at some level. I utilized NAPA Replacements Brake Parts (Calipers, Rotors and Upgraded Pads) for 2019 Mustang GT I painted the Calipers and Mounts with Polyurethane Bright Red to improve their appearance, Stainless Steel Brake Lines(from Amazon) were used. Brake Line Adaptors from EBAY connected the Male OEM fittings to the Stainless Lines. Brake Line Adaptor installed with OEM Clip to Stainless Steel Brake Line Hand Brake Modifications- The Hand Brake required a little more fabrication to function properly. I found these adaptors on Ebay although they were not designed for this particular job. The Above Two Parts were used together to adapt the OEM Hand Brake cable to the Mustang Caliper Hand Brake Cable Mount. The Cable Bracket with roll pin must be Slit to allow the cable to fit into the Threaded Cable Mount. After being inserted into the Cable Mount, the Bracket with Roll Pin is reassembled on the Cable. The Slot can hammered closed afterwards(or even tack welded) The Caliper Hand Brake Cable Mount had to be enlarged to 5/8" from 9/16"(use Unibit) to fit the Hand Brake Cable Adaptor. Insert Cable into the Nut assembly with JB Weld Epoxy to fasten cable to prevent movement. Allow 24 hours for the JB WELD to harden. Drill out Adaptor to 5/8" to provide Cable fit. /inserting Cable into Adaptor with JB Weld to hold it. I Assembled all together With the Hand Brake completely Loose, Slide Cable Roll Pin with Cotter Pin over the Caliper Lever Arm while pulling cable. Note-Stainless Brake attached to Caliper with Bolt(with copper washers-above and below. 0 The Hand Brake Adjustment Threaded Rod must be shortened by 2 1/2". Just use a Hack Saw to shorten a non- threaded portion of the Adjustment Rod. Pic of the Hand Brake Adjustment Rod in Trans Tunnel. The Shorten Adjustment Rod will move the Hand Brake Arm forward and make it easier to access. Final Hand Brake Adjustment was made when all Four Wheels were on the ground to the point the vehicle could not be pushed be hand. Wheel Spacers- With my 17" x 11 1/2" Wide Wheels and Deep Offset, the Inner Wheel Bolts would contact the Ca[iper Outer Face. US Wheel Adaptors provided 1" thick wheel spacers which get about 3/4" Caliper Clearance. I can probably shaved the Inner Side of the Spacer about 1/2" to bring the clearance down to 1/4" Clearance if necessary. Bigger Brakes with Larger Calibers and Vented Rotors would probably fit now(trial fit to be sure) if you go to LARGER Calipers and Rotors. US Wheel Adaptors can make spacers to whatever spacing that you might need. Also, the spacers can convert to different wheel mounting patterns. Wheel Inserts with 5 Lug and 4x 4 1/2" Pattern Matt Cochan at LOVE20BEE IN California found Watanabe Wheel Inserts for me. I sandblasted and took them to a local PowderCoater to powder coat. Extended Lug Nuts- Because the Narrow Wheel Lug Pockets, I went to Ebay to purchased Extra Long and Narrower Lugs. Almost all of these 14mm x1.25 lug nuts had to been retapped with Exlarge Long 14mm x 1.25 Taps because of bad threading. Extra Long Wheel Lug Nuts on Extended Wheel Studs. Next-Struts and Exhaust Pipes1 point

-

Here's the video with the CFD on the splitter diffusers:1 point

.jpg.9a495c827ef23eaabc1d5953ebb2a222.jpg)

.jpg.a28119b0a846d3cc307ea2f488edf719.jpg)

.jpg.9342f7c8ede52da0e23921e7d8cf589c.jpg)