Leaderboard

Popular Content

Showing content with the highest reputation since 12/10/04 in Posts

-

Don't tell my wife Like I tell other people. some like to fish, some like to bowl, I like to make.8 points

-

More pis of it finished up The bottom plate was beat up a bit and bent from floor jacks. So I took off the old one by drilling out the spot welds. I then drew up the shape and had a new one laser cut. The center plate that is welded to this plate, I re-made it as well, but out of 304 stainless steel. This way I can leave it a brushed stainless finish after powder coating and it is a good place to use a floor jack. I then spot welded on the larger plate in the original locations I then tigged the seam between the spot welds Then tigged on the center stainless plate Then blasted the entire cross member and powder coated it in a super black semi gloss powder coat. Powder coated the motor mounts as well I always first do a primer powder coat that is sandable I sand most off this off to fill the small blemeshes Then final coat Finally the brushed stainless plate for the floor jack Next up is getting a new transmission, then finishing the exhaust6 points

-

Been a while since I posted any updates. Been moving along. For the Turbo car I decided to build my own wheels. Ill CNC machine the center sections myself and have the lips and barrels spun for me. I really like the old SSR RS8 wheels but finding them in the correct bolt pattern, offset, and caliper clearance is impossible. I fould a set close, from Japan and had them shipped over. Since this car uses Z31 hubs and such, the spacing is out much more than a standard Z so I need a bit more positive offset. I dissasembled the wheels and scanned the center section into my computer and reverse engineered the shape. Next I re-assembled them and had the 245-45-16 tires Im going to use mounted. I test fitted them to the car, and close, but not good enough. This is the fist time this chassis has been rolling on its own wheels in 27 years. Its been on a cart or a lift. Felt good to see some progress now that the suspension, brakes, and cross-memeber are finally complete Scanned this complete assembly and put it in CAD. Now I have the exact shape of the tire on the rim. Cool cross section of it. Finally I scanned the side of the car, put it into CAD. Now I can adjust my wheel center offset for caliper clearance, and adjust it to work with new Lips and Barrels I will order for the proper offset and fit to the car. Having it in CAD alowed me to look at it from every angle and check all clearances, for calipers, springs wheels lip, ect. Even compressing the suspension to make sure I have fender clearance at full travel Final wheel spec is: Rear - 5 lug = 245-45-16 on 8.5" width rim- 27mm positive offset, 2.25" outer lip on the rim Front - 5 lug = 245-45-16 on 8.5" width rim - 31mm positive offset 1.75" outer lip on the rim Next I need to find some time to program the CNC and start cutting chips. But I got distracted on the NA car, so that update is next.5 points

-

Three weeks until I'm home and properly working on the car before a long road trip. I've been creating a detailed list on some Google notes of everything I hope to accomplish. I'll update once I truly get to it, but for now just wanted to share my excitement for my new brakes. Was in Utah about two weeks ago for a handful of days for a music conference and my brother was kind enough to let me borrow his truck to drive up to Logan just for one evening to have a quick dinner with the siblings up there and I took a quick trip to my folks' place late in the evening and opened up some of the parts to keep my motivation haha. Also had a big box of new seals from Resurrected Classics. They were kind enough to give me a steep discount on their weatherstripping kit when I asked if I could get it without the door seals since I had already purchased the S30 world seals before they released their kit. Looks like they were kind enough to give me the discount and kept the door seals anyway! I'll be making a thorough comparison of it against the Precision kit I have, mostly to see if it's truly far better for some of the worst fitting parts.5 points

-

I have two heads in stock as I type this so the head can actually be purchased. I can't help that you can't afford it. That's a feature not a bug. For the very beginning my goal was to provide the components so that talented engine builders could make the decisions on the types of components they wanted to use. Based on what I've seen and taking the pricing of the relatively simple L6 head as the baseline I highly doubt it. I'm not really sure what I did to put a burr under your saddle but you remind me of the guy that starts a fight in the line to get into the club because he can't afford the cover charge. Just get out of line and go somewhere else.5 points

-

3 years later... took ages to find a good painter willing to take on the project. These days insurance jobs with small panel fixes seem to be more profitable. Luckily I found someone willing to do it in the summer months of this year while the insurance workload is reduced. Prepping... Overall quite happy with the result. Couldn't contain myself and started puzzling together the undercarriage the first chance I got. Pulled lines in the trans tunnel and assembled the suspension component. On the wheel first the first time since 2017!5 points

-

He's saying although we are launching a DOHC head in 2024 we readily admit it will be pale in comparison the mighty KN20 from Datsunworks. At least that's what I'm hearing.5 points

-

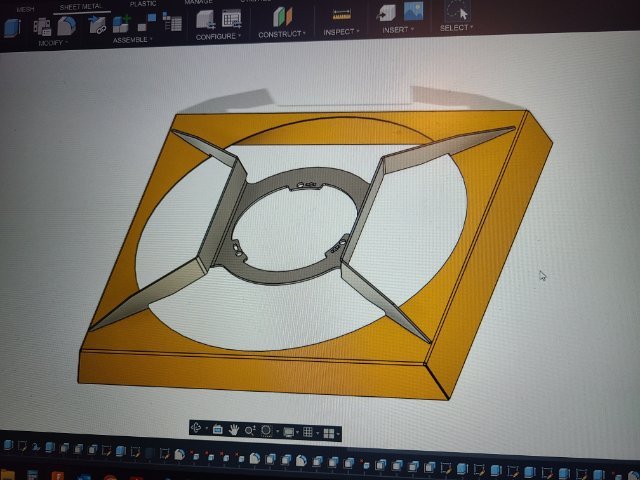

Next order of business was electric fan and shroud, and radiator hoses. I chose the 2016-2019 Camaro single SPAL 18" fan. it will be PWM controlled and is a very popular choice according to the internet as it can flow 5000CFM. Although I cut up the factory shroud to "work" I felt like I needed something fancier. modeled up a base to start working from and had my friends at laserbros in NC laser cut and bend it up. Should have gone one or two AWG thicker so added some bracing as well as some mounts and very happy with the final product. Cut down the radiator and inlets and outlets on the engine and welded on some -16an bungs, made up a couple hoses. in the last photo of the "hose installed" you can see the end of the pipe for the intake I welded into the chassis I mentioned in the previous post. Also decided to move the alternator to the other side of the engine to get it away from the heat. When i pull the engine to paint the bay i'll design and make a bracket to permanently mount it over there.4 points

-

I just wanted to share something pretty exciting in my world. 5 weeks ago I overheard a friend talking about how hard it was to get any machine work done. And it hit me..... I know how to rebuild heads I just need equipment. Did some research and found that 4 of the main shops in the area have sold out or retired. Told the idea to my father in law. And was just spit balling with him. I dont have the cash to start anything and it was just an idea.. well he gave me and my wife a rather large gift and I have now bought a storm vulcan 85b blockmaster and a winona van norman Ph-2000L valve ane seat machine. Still need a valve grinder and obviously tons of tooling. But im excited to see where God takes this. Been 25 years since ive done and work but am excited to get back into it. Plan to get the surfacer going and try to drum up some buisness to make some income to buy more tooling. I onoe they are not the best machines bit they are functional. Just wanted to share4 points

-

4 points

-

4 points

-

Went out for some Auto-x this weekend, and had a proper blast. Highly recommended for anyone here who still hasn't gone to try it. Enjoy a slow lap, some V8 noises and straight cut gearbox whine. I have a handful of things to think about and address moving forward, but overall I'm very happy with where this sits. Next up is OnGrid at the Ridge in late July for more testing, and maybe, just maaaaybe a little redemption.4 points

-

Good progress over the long weekend. Paint, bondo and fiberglass is mostly a waiting game which is pretty annoying. Got the duct glued together and painted so it looks like something. Trimmed it up a little and we are in great shape! The holes in the hood are a little bit large, but that's ok, and will likely get solved with a new hood (fiberglass) or something on top. Also got the transition piece painted which is exciting! This will help blend the splitter into the air dam, and will get taped onto the splitter once I put some trim on top of it. Need to get to work on the new intake pipe as well, going to put the filter over near the wheel for now. In the future, I'll flip the manifold and pull air from the cowl/wiper box area, but that's a bigger lift in terms of fabrication. Can't tell you how excited I am to have a metal fabrication project after 10 months of composites.4 points

-

Meh, he's a paid supporter of the site. I figured I'll give him his moneys worth4 points

-

I started typing a number of snarky responses and have settled on Wow what a shitty thing to say.4 points

-

4 points

-

**UPDATE Went to court yesterday and basically played dumb. Told the judge that "I went to the state ref and he told me since the car is so old that he couldn't do anything to certify it. So how do I go about taking car of this ticket. The vehicle is a pre smog vehicle so I've never had to SMOG it" The judge said "Ok so what Im going to do here is dismiss the case cuz it seems like your car doesn't qualify for an inspection. Sorry about the inconvenience Mr. Soto" I tried to play it cool but I was so happy. After reading all the horror stories from other people about having to revert to stock and all that I was lucky I guess Hope this thread helps someone going through something similar4 points

-

Greetings Everyone, Due to the increase in spammers HybridZ, registration has changed from being automatic to manual. That means one of the Admins will need to approve any new registrants. If you ask or tell someone about HybridZ (please do) let them know registration isn't automatic anymore. We'll do our best to stay on top of any additions and hopefully you all will see a lot less spam. Thanks, The HybridZ moderation team4 points

-

Got it off Amazon: https://amzn.to/4aS32Br And picked up a male pigtail off eBay: https://www.ebay.com/itm/134129914749 I actually replaced the wiper arms too. I used 93 miata arms which bolt up to the stock datsun wipers mechanism. Passenger arm is a little long so I may shorten it. For wiring, I followed this guide: https://www.electronixandmore.com/resources/automobiles/datsun/index.html Note this is very specific to the later wiring for 1978(maybe 1977 too) and would not be applicable to earlier years.3 points

-

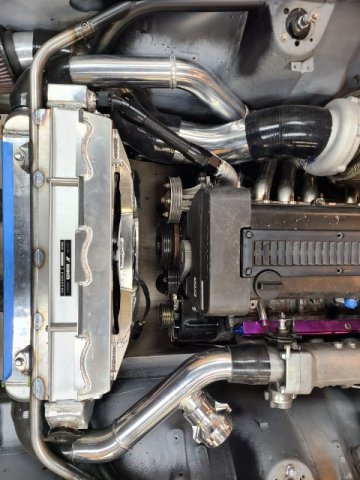

Hi All! I've owned a few s30's in the past and finally decided to build one. My car background is a lot of JDM cars including Supra's, AE86s, S13s, Skylines, a Stagea 260rs, etc. I have always loved the style of the s30 (don't we all), the aftermarket support for it and the random people who would stop me and tell me about their "Z" story. The story of this build started over a year ago when I purchased this 1978 Datsun 280z. The story behind the car (that I know of) was it is an American car that was brought to Washington and held at a speed shop awaiting restoration. Then was bought and stored in a heated warehouse for years in BC before i bought it. A little side story, I originally purchased a 1971 240z from the same person and they also had the 280z for sale but was well out of my price range. I would have loved to restore the 240z but unfortunately the amount of work it needed was well beyond my budget and experience just to get it to a useable condition. If you looked at it funny, rust would fall off the car. Mistakes we made. I was sold on what it could be but not what it will take to get there. almost a year later the 280z was still for sale, and the price was a little better. With some luck, i was able to convince the owner to trade back the 240z and cash for the 280z. Success!...Now, it seems the 280z was re-sprayed a British racing green but wasn't done the best and was flaking so i believe that's why it originally underwent the restoration in Washington. The car was just a rolling chassis, the front end had been primer epoxy'd and luckily had everything in boxes and labeled like "driver door guts", or "Rear hatch slam", which was nice to see. Now the goal of this project was to be a fun drivers, resto-mod car. It will be getting an RB26 from an r33 GTR, an RB25 transmission, DBW for the factory ITB's, Techno Toy Tuning full suspension, brakes, differential swap kit, running a Haltech S3 ECU and Wiring Specialties Harness, Poly fuel tank with an r32 skyline Radium hanger and Hellcat fuel pump. The bigger ticket items like turbo/manifold, radiator/fans, and then some smaller things are missing but most of the project is there now. I do plan of re-wiring the whole car considering I'm spending money in every other area. Now, just like anyone, I did set out with budget but considering since I last built a car, prices have gone up for parts which I stupidly didn't account for. Also a lot of, "well if i'm already doing this, then i might as well do that", and "since i have this off, i might as well get that." So the budget has been blown....but at least I'm happy! (maybe). BUT as it stands, the suspension and diff swap kit is in and the car is currently at the body shop getting the sunroof hole patched as well as some of the smaller trim holes plugged and a few small rust spots taken care of. Here are some pics throughout the build and as it stands. Any questions, advice or help for some "gotchas" will be welcome!3 points

-

11-01-2025. 260Z work. I got the engine compartment sanded down after the glaze and then cleaned up the crossmember and rack with cleaning solution "g@s" and a toothbrush, and then steel wool, etc. Then I vacuumed out the cowl and primed it with rustoleum rust primerand top coated it with gloss black paint, then painted the engine bay with filler primer. Once dry I will use some spot putty I picked up on the areas that need it, hand sand it smooth and filler primer over that. Once it is good, then I will progress to color and then clear. Busy day! Pics:3 points

-

Yes, still working on then, just have not posted anything. Bought some expensive components that take time to recover from. A blank PAMS head, that I then designed and has DelWest make me titanium intake valves, Inconel mnemonic stainless steel exhaust valves, also MoldStar 90 seats and guides. Had it assembled, and ports cleaned up for some nice flow numbers. Also purchased a Nismo 6 Speed Trans that was also strengthened and modified by HPI in Japan. I take some progress pics soon.3 points

-

3 points

-

Got the sensor figured out. It is idling around 130-140 F. Should be OK. I have to post a video. Sorry but I think this thing sounds bad ass. I have an insert in the exhaust so I dont need earplugs.3 points

-

Update: after speaking to Cortex and getting some spindle dimensions from them for CAD mockup, looks like I’ll be using their Radial X spindles. Very exciting stuff, I am a bit weary about using aluminum spindles but the car is a track car and last weighed at ~600# over each front wheel so I think I’ll be alright. Thanks! Excited to share my progress with you guys. I’d eventually like to make my work/design open source and see what more talented suspension engineers can do with it. If I didn’t just buy one of these yesterday I’d offer to trade you a complete kit for one of them KN20 heads XD. A bummer indeed, just another bump in the road! Funny you mention Stock Car blade-swaybars. It’s basically all I’ve been looking at for switching over to that design. Plus the parts are pretty cheap & standardized. Thanks everyone.3 points

-

The hairlines weren't that bad, it was the handful that were going through the edge of the rotor that I was worried about. Friday marked my first return to the track in almost 2 years. Knocked off a bunch of rust, the car worked the whole time, and I made a couple changes that were impactful and improved the car. I went pretty slow, so y'all could enjoy some v8 sounds for longer than normal3 points

-

3 points

-

Some of their stuff is good and some is hot garbage. Max the owner doesn't stand behind his product and has a tendency to try and blame "modifications" to your car as the reason. I have a lengthly (4 page) post on classic z car about my problems with his door assemblies. Resurrected Classics door problems I have their door weather strips and their fuel filler neck and the are excellent. My advice is no matter what you buy test fit as soon as it arrives and go from there. The doors were so bad that I ended up not using them. Max refuses to refund my money so I make sure to take the time to tell people about my experience. Do not trust what he says as he says whatever he needs to to get out of doing the right thing. Caveat Emptor with this guy for sure.3 points

-

You should really just post on FB because they love trolls and useless posting there3 points

-

I track my Ford powered 260Z. My personal experience is that transmission gearing is extremely important to getting the most fun on the track. In Florida, you will most likely be doing track days at Daytona and Sebring. Both tracks have very fast sections. Before doing track days, I autocrossed the car. In autocross, you only really need second gear if you have the right differential / tire height. I used Hoosier 275/35-15 tires and have a 3.36 rear end. With a 1.94 second gear in a T-5 and 6,500 rpm, 2nd gear was good for 73 mph. When I started doing track days, I needed all the gears. I had replaced the stock 1st through 4th with G-Force gears and shafts, but fifth gear was still stock. With that set-up, these were my gear ratios. 1st 2.95:1 2nd 1.94:1 3rd 1.33:1 4th 1:1 5th 0.59:1 Worked great until I needed 5th gear. that big a drop absolutely killed the fun (no acceleration in 5th). After my first time a Daytona, I changed 5th gear to 0.81:1. The .81 gear absolutely transformed the car. Now 5th gear is warp drive. The transmission that you show probably doesn't have a good selection of gear ratios, and probably won't hold much power. If it were me, I would get the new TKX with the close ratio rears. That transmission will handle the power and maximize you fun on track. If I didn't already have so much invested in my T5, I would get a TKX. This is the TKX I would get: https://www.speedwaymotors.com/TREMEC-TCET18084-TKX-Close-Ratio-5-Speed-Ford-Manual-Transmission,452007.html?srsltid=AfmBOoq-x1paVSDoNvgI38myLy79UBWXzZFW-QeQ4bK1_vWnSHM7bEEJ Gear Ratios 1st - 2.87, 2nd - 1.89, 3rd - 1.28, 4th - 1.00, 5th - 0.813 points

-

So.......it's been 7 years since my last post. The car basically sat in that drive way for a few years then pushed it in the garage for another4 years where the mice got to it. The gas in the tank and lines went to shit. I replaced the fuel pump and got it kind of running again. Obviously having the car sit outside for so long it pretty much ruined everything in the fuel system. This is where a project goes to die .....you lose interest and end up selling for cheap because it doesn't run. Well ......not this time. Last year the house where I was storing it had to be sold so I needed to find a home for it while getting it road worth again. My best friend who lives in Rochester, NY (I'm in Massachusetts) told me to trailer it to his place and we can work on it together. I know that the carbs need to get rebuilt so I decided to send them to Kyusha House. Here is the before pictures. And after Taka's absolutely amazing work.....3 points

-

Here comes the Project thread that I should've started when I picked up the car in 2021...... Firstly, I'd like to thank the person who has been the biggest help with this car, and who has ended up being one of my best friends, Andrew Mielke (who owns Milkfab Engineering). Without him the car would not be where it is today! His hybridz profile (check out his z) also shameless plug for his business: MilkFab Engineering Z acquisition: I had always wanted an s30 after growing up hearing my dad tell stories about how much he loved the gold 240z he had when him and my mom were dating. Any time we would see them at car shows or out and about i'd be drooling over them. When I started dating my now wife, I noticed a copper colored Z sticking out of a storage building on the road they lived on. Her and her family started jokingly calling it 'my car' due to me staring at it every time we'd drive past. Fast forward 3 years from then, we were married and looking for a house. She gave me a call because as she was driving to her parents house she saw the car outside and they were working on it, asked me if she should stop by and ask about it. I said 'yeah' never expecting it was actually for sale, and when they told her it was and priced it I was super surprised. This was in early 2021 when Z prices were going up dramatically, and she knew that. I told her we shouldn't get it, that it would be unwise since we needed the money for a house down payment, we had no place to put it, etc. BUT, she made me buy it, saying 'You never know if the prices are gonna keep spiking and you never be able to get one....'. So, we bought it, my parents drove over two hours to come pick it up and take it to their house where I could work on it/store it until we had our own place. My wife is a nurse and worked weekends for a while, which meant I spent many a saturday getting up at 5am, heading to my parents, working all day, then driving back in time for dinner. Over the course of 2021 I got the car 'ready' to come home, and we bought a house for it to come home to. The short of it: Where we started (There is probably more than this I'm currently not remembering) L28ET with no E or T round top su carbs lots of electrical gremlins from previous owner cutting random stuff to try and get the car running Radiator support bent from car being wrecked nasty gas tank Where we are now: Frame straightened L28ET with the E and T many fewer electrical gremlins cleaned gas tank coilovers proper race bucket seat (passenger still gets to bounce around in a nb miata seat lol) More posts to come with some build processes, pictures, stories, and more general nonsense.3 points

-

3 points

-

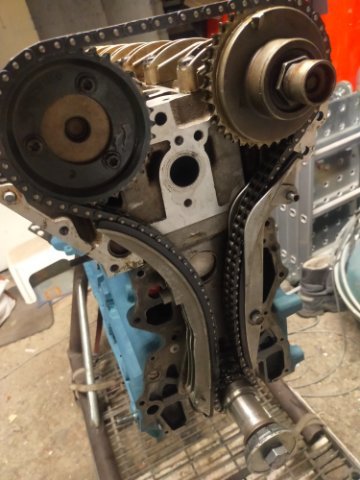

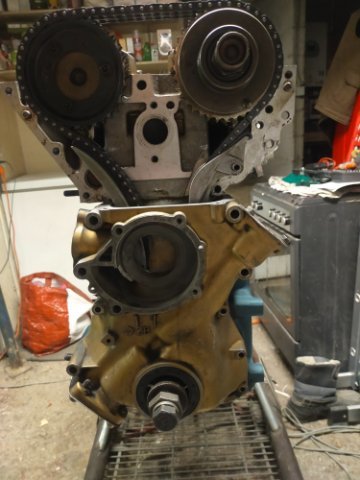

New to the forum but I wanted to make a summary of my build status/plans for my 1982 280zx. I got the car with 150k miles 7 years ago in a straight up trade for a Kawasaki Ninja 250 (crazy, I know). I was in high school/college for most of that time so my major upgrades had to wait until I got my own garage 2 years ago. Overall goal is an aggressive (~350hp) restomod that I can take to the track occasionally. I've been recording my build progress but only recently went back to edit/upload all of the videos. If you're interested in following along, subscribe to my YouTube! I'll be posting videos every 2 weeks until I'm all caught up on footage. https://www.youtube.com/@engiandesign 2018 (One year after I got the car) January 2023 Engine Bay April 2024 Engine Bay Stripped, and Painted May 2024 Engine Rebuilt July 2024 Engine Bay Mostly Complete Current Mods: Fully rebuilt L28ET Rings, bearings, studs Stock internals Valve job with new valves and seals Cometic MLS head gasket Cam sprocket and timing chain Port and polished head High volume oil pump Schneider stage 2 cam regrind with matching springs, retainers, lash pads and resurfaced rockers Ported exhaust manifold with custom external wastegate piping Tial MVS 38mm wastegate Borg warner S257 SX-e T4 7670 CXRacing Intercooler Kit Mishimoto 25 row oil cooler Mishimoto catch can Champion 3 core radiator FF Dynamics dual electric cooling fans 3.5" cold air intake 240sx 50mm throttle body Aeromotive fuel pressure regulator Upgraded 100 Amp alternator Pallnet fuel rail 1000cc Bosch EV6 injectors Megasquirt MS3x kit from Godzilla Raceworks TSP high flow fuel pump All new glowshift gauges (9 total) CXRacing 3" stainless exhaust modified with X-Force Varex valved muffler Front/rear sway bars 280z style aftermarket air dam Louvers New carpet 4 Infinity 6x9 midrange speakers with 10" Pioneer sub Future Mods Multi-spark ignition CD009 transmission swap Wilwood big brake kit Custom front grill Side skirts Rear diffuser Duck bill spoiler Fender flares Coilovers Rims/tires Seats I'm sure I'm forgetting something on this list but that's pretty much everything. I got it running in July and after a few months of dialing everything in, its finally running great! I'm currently running 9lb of boost on a very conservative tune but it still rips. Luckily my work has a chassis dyno and some very experienced tuners which should help unlock a lot more power. This winter I plan to focus on body work/aesthetics along with rims/tires/suspension. This is my first project car so I welcome any feedback or suggestions, especially related to future mods. Make sure to subscribe to my YouTube for more updates!3 points

-

Before removing the diff, I would check the u-joints on your driveshaft as well.3 points

-

Bumping zboi's thread so he can continue his contributions to the community. Let's see an update.3 points

-

My opinion: Flares because your tires are fat and need room = cool. Skinny tires that should fit stock but spaced way out anyway = not cool. It's in the same vein as camber to me. Negative camber for better handling? Awesome. Crazy negative camber because you want people to know how much camber you have? Stupid.3 points

-

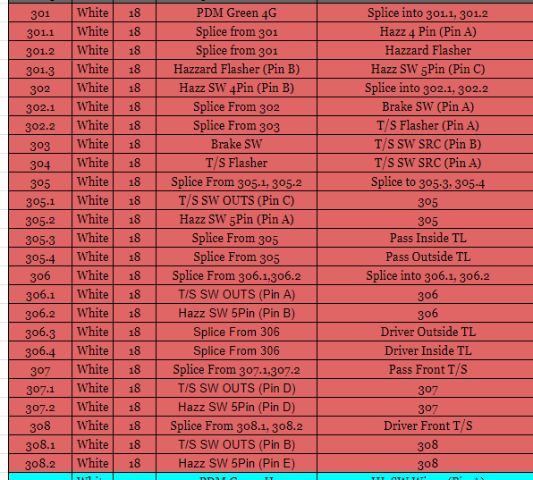

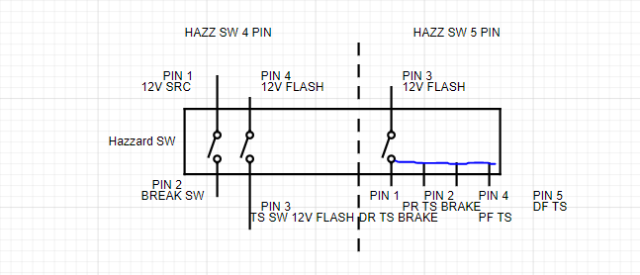

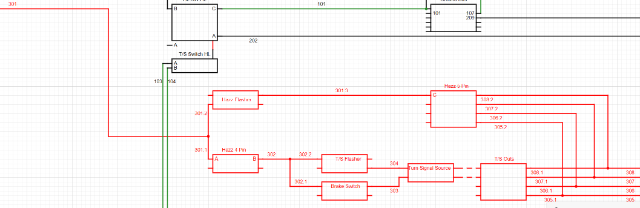

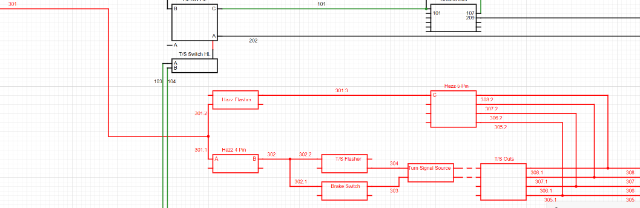

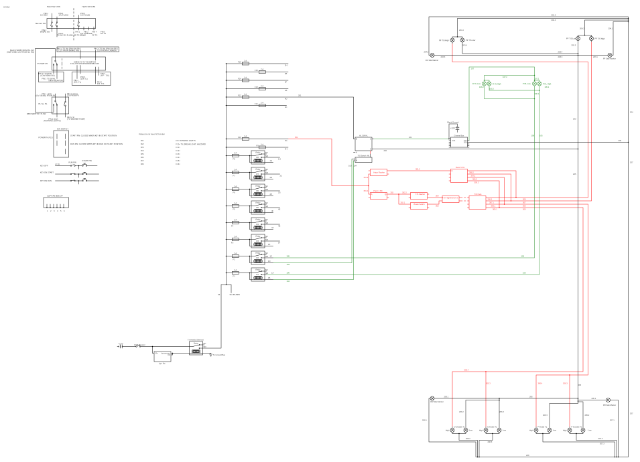

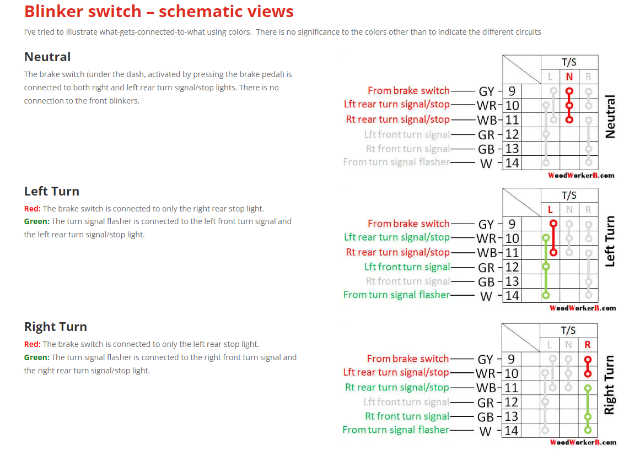

A few notes before I get into it 1.I am rewiring my car from scratch. So I have no clue what color wires correspond to what pins, or what year switches I am using 70-78 2. I'm not using the stock taillights, I only have an off, high and low signal, all red(Think Semi trailer lights). So the way I wired stuff might be different for you 3.I feel that if you understand the concept of what I am showing below you can adapt what you have to create something similar. I am an idiot when it comes to wiring, but I got this to work for me so feel free to copy it at your own risk haha. This definitely isn't stock Hazard switch (Ignore the PinX stuff for now, That is how I am keeping track of what wire is going to what pin on the connectors I have) I see the hazard switch as the first step in how the power is routed. The switch has two different states (Noted by the vertical dashed line in the image above), on and off, each with it's own outcome. Hazards on: (Right side of above image) 5 Pins should be connected on the switch when the hazard switch is on/closed, use a multimeter to test continuity between all the pins, and note which ones are connected. One of the pins should receive 12v + from a flasher unit (I am using a PDM (Bussman31s002) to get fused 12v power, then putting that into a 3 wire flasher unit that is adjustable to set the timing of the flashes). So when I have my hazard switch on, power flows through the pdm, then into the flasher, into one of the 5 connected pins on the Haz SW, then a wire out to each of the 4 turn signal lights. This also kills all connections to the "Off" side of the switch. In my case, this disables the turn signals, and brake lights. Hazards off: (left side of above image) there are going to be two sets of two pins that are connected when the hazards are off/closed. Use a multimeter, check continuity, write it down. Feed one of the pairs with fused 12v+. The pin that is connected to the 12v+ gets a wire that is spliced into 2 different locations. Location 1 is the brake switch. Location 2 is a second Flasher unit. These two wires then come back together to feed the Turn signal switch, one flashing, one constant. When the switch is in this position, everything on the right side of the above image is no longer connected. Turn Signal Switch The Turn Signal Switch works off of two inputs 12v constant (Connected to 2 pins that should correspond with your Brake lights, and will disconnect from one of the pins if the turn signals are on in that direction) and 12v flashing (Connected to either the front left and rear left, front right and rear right pins, or no pins at all depending on the location of the stalk. So, for me, If my brakes are on, I get a signal to the "high" side of my tail light. WoodworkerB's website is invaluable. I recreated all of his diagrams with the corresponding wire color of my switch to use for my own project. https://woodworkerb.com/home/datsun-240z-rebuild/blinker-detail/ https://woodworkerb.com/home/datsun-240z-rebuild/datsun-240z-multifunction-switches/ Below I have a schematic of what the whole thing looks like, minus the detail of what the internals of the switches are actually doing, as well as the pinouts. (right most column is where the wire terminates, to its left is where it starts) Looks like the images are tough to read. DM me if you want a full size copy. Let me know if you have questions, or tell me that I'm wrong haha, The harness still in the basement so I would rather fix stuff now than when it is in the car. But as is the lighting system is functional, I pulled out a bunch of stuff to test it all.3 points

-

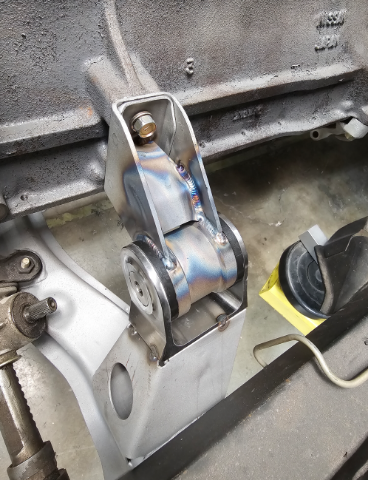

I finished up the front crossmember and motor mounts Started with a stock crossmember with the need for new engine mounting since I moved the engine in the chassis back about 1 inch. I extended and boxed in the existing upright Some grinding and blasting to clean it up 3 D printed mockup of a machined bracket I made to accept the moustache bar busings. I designed these years ago and have been in the NA car for 15 years. Worked well I machined this weld in bracket out of a solid chunk of steel because I wanted the details for the bolt holes and you could not do that with bent sheet metal. Stupid but fun. More soon3 points

-

3 points

-

That makes all domestic orders shipped! One international to figure out still. Thanks again for everyone's patience while I got through these. I didn't anticipate it to take 6 months! Final tally on the donation amount to come as soon as I tally things up, but it will be over $1k. Funds have been flowing to Dan as needed over the last 6 months 1. 7d2jz 2. MAG58 - PAID - SHIPPED 3. MAG58 - PAID- SHIPPED 4. Crespo79 - PAID- SHIPPED 5. Jeffrox - PAID- SHIPPED 6. jhm - PAID- SHIPPED 7. onthego- - PAID- SHIPPED 8. onthego- - PAID- SHIPPED 9. pepper - PAID- SHIPPED 10. pepper - PAID- SHIPPED 11. ModernS30 - PAID- SHIPPED 12. Masonvonritchie - PAID- SHIPPED 13. rxx2rxx2 - PAID- SHIPPED 14. rxx2rxx2 - PAID- SHIPPED 15. Sonethirty - PAID- SHIPPED 16. S30TRBO - PAID- SHIPPED 17. S30TRBO - PAID- SHIPPED 18. Kennysgreen280zt - PAID- SHIPPED 19. Kennysgreen280zt - PAID- SHIPPED 20. Kennysgreen280zt - PAID- SHIPPED 21. ElliottOhZ - PAID- SHIPPED 22. Oki570Z - PAID- SHIPPED 23. lowrider - PAID- SHIPPED 24. lowrider - PAID- SHIPPED 25. lowrider - PAID- SHIPPED 26. jnjdragracing - PAID- SHIPPED 27. jnjdragracing - PAID- SHIPPED 28. OldAndyAndTheSea - PAID- SHIPPED 29. OldAndyAndTheSea - PAID- SHIPPED 30. JonRHD - PAID- SHIPPED 31. JonRHD - PAID- SHIPPED 32. 75280z - PAID- SHIPPED 33. 75280z - PAID- SHIPPED 34. CalZ - PAID- SHIPPED 35. CalZ - PAID- SHIPPED 36. LanceVance - PAID- SHIPPED 37. LanceVance - PAID- SHIPPED 38. Stunt 39. Stunt 40. _akuma_no_zetto_ - PAID- SHIPPED 41. _akuma_no_zetto_ - PAID- SHIPPED 42. 1 tuff z - PAID- SHIPPED 43. 1 tuff z - PAID- SHIPPED 44. Zlost - PAID- SHIPPED 45. AydinZ71 - PAID- SHIPPED 46. AydinZ71 - PAID- SHIPPED 47. zredbaron - PAID- SHIPPED 48. zredbaron - PAID- SHIPPED 49. zredbaron - PAID- SHIPPED 50. airbrush-ed 51. Chris Damato (FB) - PAID- SHIPPED 52. Chris Damato (FB) - PAID- SHIPPED 53. evildky - PAID- SHIPPED 54. torqen2k1 - PAID- SHIPPED 55. torqen2k1 - PAID- SHIPPED 56. torqen2k1 - PAID- SHIPPED 57. torqen2k1 - PAID- SHIPPED 58. torqen2k1 - PAID- SHIPPED 59. torqen2k1 - PAID- SHIPPED 60. Mayolives - PAID- SHIPPED 61. Mayolives - PAID- SHIPPED 62. Mayolives - PAID- SHIPPED 63. bkz72 - PAID- SHIPPED 64. Wizzurp - PAID- SHIPPED 65. Wizzurp - PAID- SHIPPED 66. Leon - PAID- SHIPPED 67. Gollum - PAID- SHIPPED 68. Gollum - PAID- SHIPPED 69. Gollum - PAID- SHIPPED 70. AB240z - PAID- SHIPPED 71. AB240z - PAID- SHIPPED 72. AB240z - PAID- SHIPPED 73. AB240z - PAID- SHIPPED 74. AB240z - PAID- SHIPPED 75. AB240z - PAID- SHIPPED 76. AB240z - PAID- SHIPPED 77. AB240z - PAID- SHIPPED 78. AB240z - PAID- SHIPPED 79. Zetsaz - PAID- SHIPPED 80. Zetsaz - PAID- SHIPPED 81. Zetsaz - PAID- SHIPPED 82. Wedge 83. 24Oz - PAID 84. ihavearustedz - PAID- SHIPPED 85. clarkspeed - PAID- SHIPPED 86. niner11 - PAID- SHIPPED 87. 1970 240z - PAID- SHIPPED 88. 1970 240z - PAID- SHIPPED 89. 1970 240z - PAID- SHIPPED 90. 1970 240z - PAID- SHIPPED3 points

-

3 points

-

Even if 100 people commited to purchase, its still tiny small numbers vs an OEM production. Its got to be done out of passion and at least not to lose money. This is why this is such a huge acomplisment for someone like Derek, We are fortunate the passion runs deep. I cant imagine the hours of "un-billed" time3 points

-

Unfortunately, it is too late. Maybe for round 6 in a couple of years Got the shirts in and will start breaking things down and shipping things out next week. This week is busy with work travel, so appreciate your patience while I get a few out each day on my lunch breaks.3 points

-

They received all of the shirts without backorders and are starting on printing this afternoon!3 points

-

I really wish things would swing back towards the forums. I can't tell you how many times I know the answer to or could add to a post on FB but I don't since it really has no longevity. I always felt like I was adding to the overall knowledge base when I posted here. I can go on and on but I really hate it.3 points

-

First start up since starting the restoration. Kind of shocked she started right up on the first go. Was expecting something on the MegaJolt to need fixing, but it worked great. Went with Magnacor wires, but they made a mistake and did not fit them up with the right coil boots. Being remade and shipped, so I am using 05’ ford explorer NGK wires for now. Went with a “7” heat NGK plug on account of the 10:1 CR. It’s raining this weekend, but just need to dial-in some crude alignment and she will be road worthy IMG_2339.mov3 points

-

3 points

-

3 points

-

an LS is also vastly more expensive then a traditional 350 swap. He should do whatever he wants to do.3 points

.png.00ba7668e3b86ef19d6564579d3fca92.png)