Leaderboard

Popular Content

Showing content with the highest reputation since 02/15/25 in Posts

-

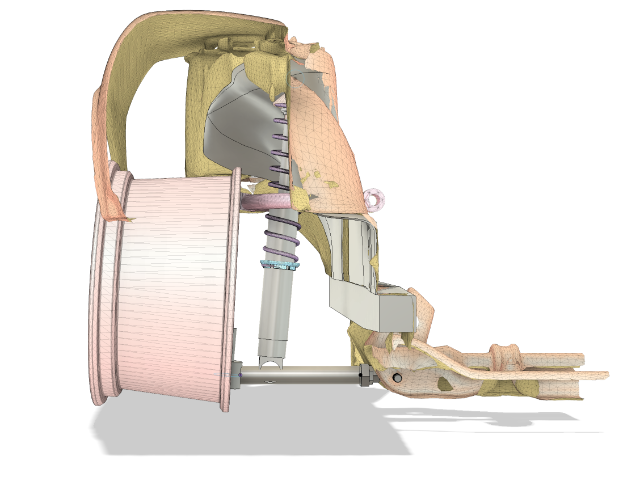

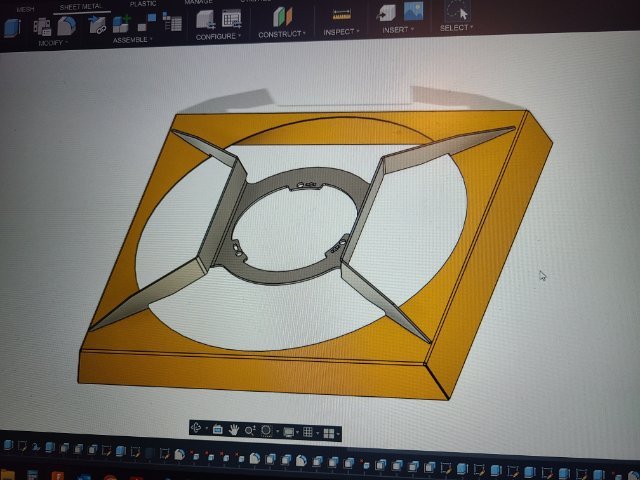

Been a while since I posted any updates. Been moving along. For the Turbo car I decided to build my own wheels. Ill CNC machine the center sections myself and have the lips and barrels spun for me. I really like the old SSR RS8 wheels but finding them in the correct bolt pattern, offset, and caliper clearance is impossible. I fould a set close, from Japan and had them shipped over. Since this car uses Z31 hubs and such, the spacing is out much more than a standard Z so I need a bit more positive offset. I dissasembled the wheels and scanned the center section into my computer and reverse engineered the shape. Next I re-assembled them and had the 245-45-16 tires Im going to use mounted. I test fitted them to the car, and close, but not good enough. This is the fist time this chassis has been rolling on its own wheels in 27 years. Its been on a cart or a lift. Felt good to see some progress now that the suspension, brakes, and cross-memeber are finally complete Scanned this complete assembly and put it in CAD. Now I have the exact shape of the tire on the rim. Cool cross section of it. Finally I scanned the side of the car, put it into CAD. Now I can adjust my wheel center offset for caliper clearance, and adjust it to work with new Lips and Barrels I will order for the proper offset and fit to the car. Having it in CAD alowed me to look at it from every angle and check all clearances, for calipers, springs wheels lip, ect. Even compressing the suspension to make sure I have fender clearance at full travel Final wheel spec is: Rear - 5 lug = 245-45-16 on 8.5" width rim- 27mm positive offset, 2.25" outer lip on the rim Front - 5 lug = 245-45-16 on 8.5" width rim - 31mm positive offset 1.75" outer lip on the rim Next I need to find some time to program the CNC and start cutting chips. But I got distracted on the NA car, so that update is next.5 points

-

Three weeks until I'm home and properly working on the car before a long road trip. I've been creating a detailed list on some Google notes of everything I hope to accomplish. I'll update once I truly get to it, but for now just wanted to share my excitement for my new brakes. Was in Utah about two weeks ago for a handful of days for a music conference and my brother was kind enough to let me borrow his truck to drive up to Logan just for one evening to have a quick dinner with the siblings up there and I took a quick trip to my folks' place late in the evening and opened up some of the parts to keep my motivation haha. Also had a big box of new seals from Resurrected Classics. They were kind enough to give me a steep discount on their weatherstripping kit when I asked if I could get it without the door seals since I had already purchased the S30 world seals before they released their kit. Looks like they were kind enough to give me the discount and kept the door seals anyway! I'll be making a thorough comparison of it against the Precision kit I have, mostly to see if it's truly far better for some of the worst fitting parts.5 points

-

I have two heads in stock as I type this so the head can actually be purchased. I can't help that you can't afford it. That's a feature not a bug. For the very beginning my goal was to provide the components so that talented engine builders could make the decisions on the types of components they wanted to use. Based on what I've seen and taking the pricing of the relatively simple L6 head as the baseline I highly doubt it. I'm not really sure what I did to put a burr under your saddle but you remind me of the guy that starts a fight in the line to get into the club because he can't afford the cover charge. Just get out of line and go somewhere else.5 points

-

Next order of business was electric fan and shroud, and radiator hoses. I chose the 2016-2019 Camaro single SPAL 18" fan. it will be PWM controlled and is a very popular choice according to the internet as it can flow 5000CFM. Although I cut up the factory shroud to "work" I felt like I needed something fancier. modeled up a base to start working from and had my friends at laserbros in NC laser cut and bend it up. Should have gone one or two AWG thicker so added some bracing as well as some mounts and very happy with the final product. Cut down the radiator and inlets and outlets on the engine and welded on some -16an bungs, made up a couple hoses. in the last photo of the "hose installed" you can see the end of the pipe for the intake I welded into the chassis I mentioned in the previous post. Also decided to move the alternator to the other side of the engine to get it away from the heat. When i pull the engine to paint the bay i'll design and make a bracket to permanently mount it over there.4 points

-

I just wanted to share something pretty exciting in my world. 5 weeks ago I overheard a friend talking about how hard it was to get any machine work done. And it hit me..... I know how to rebuild heads I just need equipment. Did some research and found that 4 of the main shops in the area have sold out or retired. Told the idea to my father in law. And was just spit balling with him. I dont have the cash to start anything and it was just an idea.. well he gave me and my wife a rather large gift and I have now bought a storm vulcan 85b blockmaster and a winona van norman Ph-2000L valve ane seat machine. Still need a valve grinder and obviously tons of tooling. But im excited to see where God takes this. Been 25 years since ive done and work but am excited to get back into it. Plan to get the surfacer going and try to drum up some buisness to make some income to buy more tooling. I onoe they are not the best machines bit they are functional. Just wanted to share4 points

-

4 points

-

4 points

-

Went out for some Auto-x this weekend, and had a proper blast. Highly recommended for anyone here who still hasn't gone to try it. Enjoy a slow lap, some V8 noises and straight cut gearbox whine. I have a handful of things to think about and address moving forward, but overall I'm very happy with where this sits. Next up is OnGrid at the Ridge in late July for more testing, and maybe, just maaaaybe a little redemption.4 points

-

Good progress over the long weekend. Paint, bondo and fiberglass is mostly a waiting game which is pretty annoying. Got the duct glued together and painted so it looks like something. Trimmed it up a little and we are in great shape! The holes in the hood are a little bit large, but that's ok, and will likely get solved with a new hood (fiberglass) or something on top. Also got the transition piece painted which is exciting! This will help blend the splitter into the air dam, and will get taped onto the splitter once I put some trim on top of it. Need to get to work on the new intake pipe as well, going to put the filter over near the wheel for now. In the future, I'll flip the manifold and pull air from the cowl/wiper box area, but that's a bigger lift in terms of fabrication. Can't tell you how excited I am to have a metal fabrication project after 10 months of composites.4 points

-

Meh, he's a paid supporter of the site. I figured I'll give him his moneys worth4 points

-

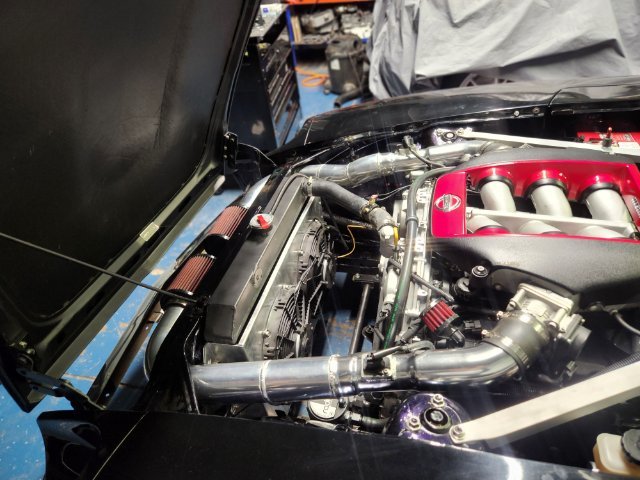

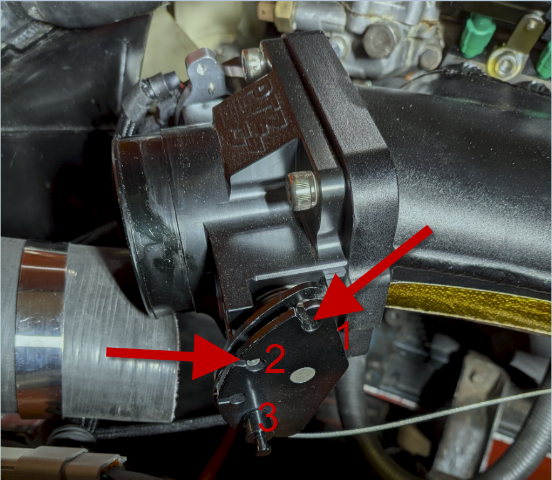

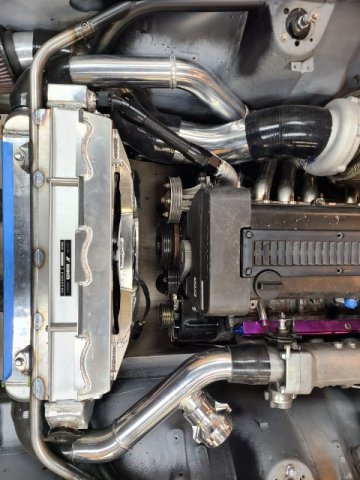

Hi everyone, I am at a good point with my build and wanted to share its history since its one of the few running and driving VQ37 swapped Zs in the country. I am going on over a decade of ownership. I originally bought the car from New Mexico and brought it over to Colorado. Come to find out, it was once a Colorado car also. I picked it up in primer with a rebuilt engine but not really knowing too much about it since all I had were photos and the owners word. The previous owner used it for autocross. The entire interior was missing and it had a rats nest for wiring. I remember it had a switch to manually turn on the fans. It also had a full radiator support and driver side frame rail replacement from a donor Z. I got lucky that this was done really well, I have had no problems getting the car aligned over the years and it drives straight! I saved some money and got the car painted in black, the car was originally a yellow car. The painter actually welded in floor boards and frame rails and closed up the wheel wells from where they were cut for the ZG flares. The rear hatch had to get replaced since it had an inch of bondo over the key hole. Luckily, I was able to track a hatch from a 240Z in the junk yard (when is the last time you have seen that haha). I added sound deadner to the interior and then took the car to an upholstery shop to get the interior put it. I also added some nice gauges. I was able to source some cheap Watanabe 16 inch wheels from yahoo auction Japan. They were different colors but I ended up paying around 900 usd after air shipping them spent another 300 getting them powder coated. I also picked up my Recaro seats from Japan. To this day I have no idea what car they came from but they are one of my favorite parts of the car. The SUs where swapped out for a triple Mikuni 44s. I drove with those and even had them tuned but they were too finnicky at altitude. During this time I got into flipping carbs for resale. I didn't want to deal with the Mikunis and decided to swap to fuel injection. I ended going Jenvey ITBs on Haltech. This setup actually worked great for about a year and even made it to the main page of my local Cars and Coffee. Around that summer I started to develop some running problems where I was running too rich. On my way to the tuner the worst thing happened. The car caught fire. From what I could tell, the itbs backfired and caught the fuel line on fire. If anyone is running itbs on an L Series, I highly recommend an airbox. I got really lucky since a guy like 2 cars back behind me had a fire extinguisher and that the radiator hose blew and stopped the fire. I sent the car over to my tuner/builder and waited on my insurance adjuster to visit the car. I was able to get a full payout through Hagerty and that kickstarted the funds to get my Z back on the road again. I knew I was done with L series. I never really wanted to build something that close to race car since I mostly drive my Z on the streets and occasional canyons. I wanted to stick something Nissan that could remain relatively stock. Something I could start up and just drive. In the past I almost swapped VQ35HR motor and have always had that build in the back on my mind but I noticed that the engines were almost the same price as the bigger brother VQ37. So I went with a VQ37 out of an automatic AWD G37. The reason I chose that engine was to avoid 370z's had been driven hard and the auto engines were cheaper with less mileage. The only change to the block that I needed was a lower oil pan from a RWD VQ and its bolts. I sourced a transmission directly from Nissan since at that time it was actually only about 500 dollars more compared to a used transmission. I looked recently and it seems like the transmission have doubled in price since 2021 when I bought mine. Here are the photos of when I got her back. We ended up putting some flake in the engine bay since I grew up loving lowriders. I also installed a GTR intake conversion. It ended up being a bit of a hassle since the custom fuel rail didn't clear the injectors. We had to extend the fuel ports on the fuel rail to make them taller so that it could clear. I added a catch can since the car is set to vent to atmosphere. I pulled the headers and stripped them and cerakoted them also. The custom hood didn't make it out of the fire so I went carbon fiber. Next I ended up getting the intakes extended to the front of the car to make it a true cold air intake. I recently took the Z engine harness apart and reloomed it and fixed one of my turn signals. Come to find out one of the wires was cut off. With the help of Dave Irwin, I was able to track down all of my missing grounds and also why both lights would blink at the same time (bad switch). I had an extra parts turn signal switch which I harvested and was able to get everything to work out. I recently tackled getting my horn to work. I have never got it to work since my entire ownership. The guys at classiczcar forum really helped me trouble shoot it. Come to find out, my only horn didn't work and for some reason my steering rack wasn't grounded. This is pretty much where the car is now. I took her to a local car meet today and I am hoping to just get more seat time with her. If anyone has any questions about the car or the swap feel free to message me.3 points

-

Got it off Amazon: https://amzn.to/4aS32Br And picked up a male pigtail off eBay: https://www.ebay.com/itm/134129914749 I actually replaced the wiper arms too. I used 93 miata arms which bolt up to the stock datsun wipers mechanism. Passenger arm is a little long so I may shorten it. For wiring, I followed this guide: https://www.electronixandmore.com/resources/automobiles/datsun/index.html Note this is very specific to the later wiring for 1978(maybe 1977 too) and would not be applicable to earlier years.3 points

-

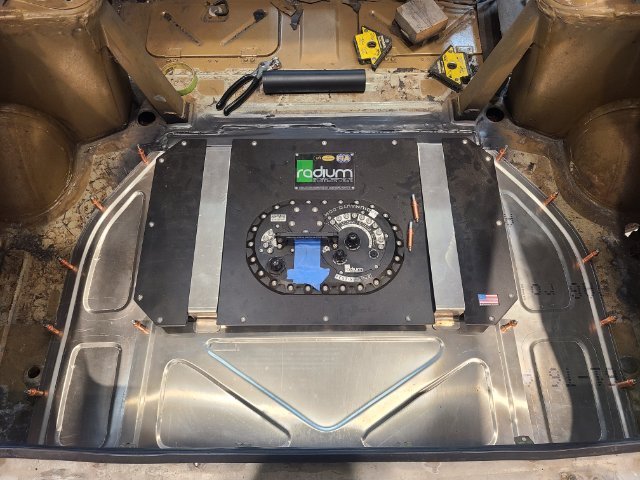

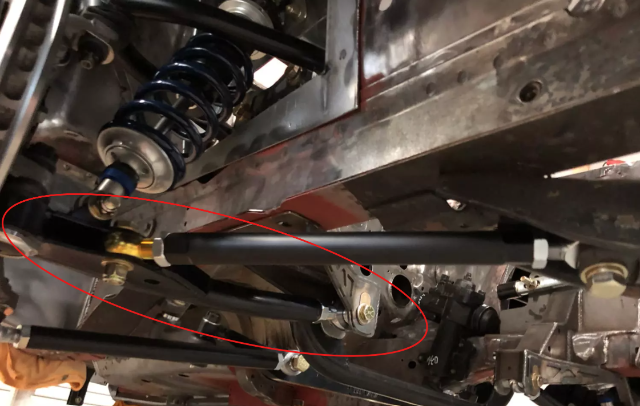

Hi All! I've owned a few s30's in the past and finally decided to build one. My car background is a lot of JDM cars including Supra's, AE86s, S13s, Skylines, a Stagea 260rs, etc. I have always loved the style of the s30 (don't we all), the aftermarket support for it and the random people who would stop me and tell me about their "Z" story. The story of this build started over a year ago when I purchased this 1978 Datsun 280z. The story behind the car (that I know of) was it is an American car that was brought to Washington and held at a speed shop awaiting restoration. Then was bought and stored in a heated warehouse for years in BC before i bought it. A little side story, I originally purchased a 1971 240z from the same person and they also had the 280z for sale but was well out of my price range. I would have loved to restore the 240z but unfortunately the amount of work it needed was well beyond my budget and experience just to get it to a useable condition. If you looked at it funny, rust would fall off the car. Mistakes we made. I was sold on what it could be but not what it will take to get there. almost a year later the 280z was still for sale, and the price was a little better. With some luck, i was able to convince the owner to trade back the 240z and cash for the 280z. Success!...Now, it seems the 280z was re-sprayed a British racing green but wasn't done the best and was flaking so i believe that's why it originally underwent the restoration in Washington. The car was just a rolling chassis, the front end had been primer epoxy'd and luckily had everything in boxes and labeled like "driver door guts", or "Rear hatch slam", which was nice to see. Now the goal of this project was to be a fun drivers, resto-mod car. It will be getting an RB26 from an r33 GTR, an RB25 transmission, DBW for the factory ITB's, Techno Toy Tuning full suspension, brakes, differential swap kit, running a Haltech S3 ECU and Wiring Specialties Harness, Poly fuel tank with an r32 skyline Radium hanger and Hellcat fuel pump. The bigger ticket items like turbo/manifold, radiator/fans, and then some smaller things are missing but most of the project is there now. I do plan of re-wiring the whole car considering I'm spending money in every other area. Now, just like anyone, I did set out with budget but considering since I last built a car, prices have gone up for parts which I stupidly didn't account for. Also a lot of, "well if i'm already doing this, then i might as well do that", and "since i have this off, i might as well get that." So the budget has been blown....but at least I'm happy! (maybe). BUT as it stands, the suspension and diff swap kit is in and the car is currently at the body shop getting the sunroof hole patched as well as some of the smaller trim holes plugged and a few small rust spots taken care of. Here are some pics throughout the build and as it stands. Any questions, advice or help for some "gotchas" will be welcome!3 points

-

Great work so far! I’m sure this will be an awesome build. I suspect you will be running fender flares or a wide body kit seeing as your wheels are poking out a bit?3 points

-

11-01-2025. 260Z work. I got the engine compartment sanded down after the glaze and then cleaned up the crossmember and rack with cleaning solution "g@s" and a toothbrush, and then steel wool, etc. Then I vacuumed out the cowl and primed it with rustoleum rust primerand top coated it with gloss black paint, then painted the engine bay with filler primer. Once dry I will use some spot putty I picked up on the areas that need it, hand sand it smooth and filler primer over that. Once it is good, then I will progress to color and then clear. Busy day! Pics:3 points

-

Yes, still working on then, just have not posted anything. Bought some expensive components that take time to recover from. A blank PAMS head, that I then designed and has DelWest make me titanium intake valves, Inconel mnemonic stainless steel exhaust valves, also MoldStar 90 seats and guides. Had it assembled, and ports cleaned up for some nice flow numbers. Also purchased a Nismo 6 Speed Trans that was also strengthened and modified by HPI in Japan. I take some progress pics soon.3 points

-

3 points

-

Got the sensor figured out. It is idling around 130-140 F. Should be OK. I have to post a video. Sorry but I think this thing sounds bad ass. I have an insert in the exhaust so I dont need earplugs.3 points

-

Update: after speaking to Cortex and getting some spindle dimensions from them for CAD mockup, looks like I’ll be using their Radial X spindles. Very exciting stuff, I am a bit weary about using aluminum spindles but the car is a track car and last weighed at ~600# over each front wheel so I think I’ll be alright. Thanks! Excited to share my progress with you guys. I’d eventually like to make my work/design open source and see what more talented suspension engineers can do with it. If I didn’t just buy one of these yesterday I’d offer to trade you a complete kit for one of them KN20 heads XD. A bummer indeed, just another bump in the road! Funny you mention Stock Car blade-swaybars. It’s basically all I’ve been looking at for switching over to that design. Plus the parts are pretty cheap & standardized. Thanks everyone.3 points

-

This is awesome. We haven't had a good engineering project on here in a while, so this is a good to see.3 points

-

The hairlines weren't that bad, it was the handful that were going through the edge of the rotor that I was worried about. Friday marked my first return to the track in almost 2 years. Knocked off a bunch of rust, the car worked the whole time, and I made a couple changes that were impactful and improved the car. I went pretty slow, so y'all could enjoy some v8 sounds for longer than normal3 points

-

3 points

-

Some of their stuff is good and some is hot garbage. Max the owner doesn't stand behind his product and has a tendency to try and blame "modifications" to your car as the reason. I have a lengthly (4 page) post on classic z car about my problems with his door assemblies. Resurrected Classics door problems I have their door weather strips and their fuel filler neck and the are excellent. My advice is no matter what you buy test fit as soon as it arrives and go from there. The doors were so bad that I ended up not using them. Max refuses to refund my money so I make sure to take the time to tell people about my experience. Do not trust what he says as he says whatever he needs to to get out of doing the right thing. Caveat Emptor with this guy for sure.3 points

-

You should really just post on FB because they love trolls and useless posting there3 points

-

I track my Ford powered 260Z. My personal experience is that transmission gearing is extremely important to getting the most fun on the track. In Florida, you will most likely be doing track days at Daytona and Sebring. Both tracks have very fast sections. Before doing track days, I autocrossed the car. In autocross, you only really need second gear if you have the right differential / tire height. I used Hoosier 275/35-15 tires and have a 3.36 rear end. With a 1.94 second gear in a T-5 and 6,500 rpm, 2nd gear was good for 73 mph. When I started doing track days, I needed all the gears. I had replaced the stock 1st through 4th with G-Force gears and shafts, but fifth gear was still stock. With that set-up, these were my gear ratios. 1st 2.95:1 2nd 1.94:1 3rd 1.33:1 4th 1:1 5th 0.59:1 Worked great until I needed 5th gear. that big a drop absolutely killed the fun (no acceleration in 5th). After my first time a Daytona, I changed 5th gear to 0.81:1. The .81 gear absolutely transformed the car. Now 5th gear is warp drive. The transmission that you show probably doesn't have a good selection of gear ratios, and probably won't hold much power. If it were me, I would get the new TKX with the close ratio rears. That transmission will handle the power and maximize you fun on track. If I didn't already have so much invested in my T5, I would get a TKX. This is the TKX I would get: https://www.speedwaymotors.com/TREMEC-TCET18084-TKX-Close-Ratio-5-Speed-Ford-Manual-Transmission,452007.html?srsltid=AfmBOoq-x1paVSDoNvgI38myLy79UBWXzZFW-QeQ4bK1_vWnSHM7bEEJ Gear Ratios 1st - 2.87, 2nd - 1.89, 3rd - 1.28, 4th - 1.00, 5th - 0.813 points

-

For a street car I think the rails make sense. For a race car that has a cage perhaps not. For a similar amount of weight you can triangulate the cage with tubing on top of the floor that extends to the suspension pickup points.3 points

-

So.......it's been 7 years since my last post. The car basically sat in that drive way for a few years then pushed it in the garage for another4 years where the mice got to it. The gas in the tank and lines went to shit. I replaced the fuel pump and got it kind of running again. Obviously having the car sit outside for so long it pretty much ruined everything in the fuel system. This is where a project goes to die .....you lose interest and end up selling for cheap because it doesn't run. Well ......not this time. Last year the house where I was storing it had to be sold so I needed to find a home for it while getting it road worth again. My best friend who lives in Rochester, NY (I'm in Massachusetts) told me to trailer it to his place and we can work on it together. I know that the carbs need to get rebuilt so I decided to send them to Kyusha House. Here is the before pictures. And after Taka's absolutely amazing work.....3 points

-

A new year has started and my battle to get the 280z road worthy goes on. I had liked to get some more things done over the holidays but sickness and other obligations got the better of me. That doesn’t mean I didn’t get some progress in. To prepare for a new years eve party I had to temporarily get the Z inside the garage so I continued my journey of stripping down the Z by removing the fenders and wiper cowl. I kind of regret but I'm also glad I did. Turns out the last “restauration” was a fairly cheap one. Some threads where damaged and instead of repairing the thread or welding in a nut they just left the bolts out, or in case of the lower mounting points of the fenders just weld and bondo them on. After getting them off I was met with the nice surprise of finding out they never painted the inside/back of the fenders or any non-exterior part for that matter, only primer. As a result I was met with a lot of surface corrosion spots. I also discovered the car has some crash damage on the front left that was never properly repaired. Some sanding, rust treatment and painting later the car already looked a lot better. At least now I know the Z won’t rust away in the next couple of years. Every panel I remove it becomes more and more clear that a full restauration to the bare metal of the body is necessary if I want this Z to survive at least another 10 to 20 years. I really wanted to start installing some of my new goodies from Apex so I decided to install the rear strut brace as it won’t interfere with any of the bodywork. It was freezing outside but with the help of a heater it was quit doable. I do love the look of the Apex rear strut brace. It’s strong, elegant, functional but doesn’t scream “aftermarket modification” which I like a lot. I don’t really want my car to stay stock but also not heavily modified, just tasteful, functional and a bit more modernized but still the classic look and feel. The last few couple of days have been pretty cold so I moved back to the garage for some of the car work. Unfortunately my garage isn’t insolated and I don’t have a strong enough heater but it’s better then outside and good enough for some paint work and rebuilding the hinges. Rebuilding the hinges was easier then I though at first. Having a vice does make life a lot easier when removing and installing the hinge pins. To get them out I just used an impact socket and an old bolt that was slightly smaller then the hinge pin. With some force they came right out. All hinge pins where worn which caused the doors to sag and the passenger side (which sagged the most) was even bent! The rebuild kit I bought from Zservices EU was great with the exception of the hinge pin bushings, both the outer and inner tolerance was out of spec on all of them. If it was to tight then that wouldn’t be that much of a problem as I could modify them but the tolerance was to loose causing the bushings to sit loosely in the hinge and the pin to have some play. I decided to rebuild the passenger side hinges anyway and will install them soon to see if they sag with these bushings installed. If they do I will have some custom made at a machine shop. Continuing with the doors I decided to do some spot repair on the upper corners of the doors as both sides had some corrosion under the paint, and the doors where off the car anyway so might as well do them now. Here to I discovered the inside of the door was never painted causing some corrosion on the inside of the doors. The more I work on the car the more I want to punch the previous owner and bodyshop in the face. Even so I can't wait to drive the Z, I guess that’s the S30 life for yea….2 points

-

For you that have been following along. My 3.12L is finally in my car and home. Gosh it looks so good I’m just going to stare at it! Amazing work by Andrew Kazanis! This engine was built and done prior to a shop fire. So it’s been through a lot! I love the contrast of the stock blue block and gold zinc and black. It features. My 3.1L 10.2:1 compression ratio 88.5mm bore. N42 block. Sonic tested. LD crank by marine crankshaft. Crank �Off-set grind to 84.6 stroke�Finish rod journals @ 1.8889" Thrust Finish 1.27”�R & R plugs with threaded plugs�Dynamic Balance�Ion-Plasma nitride, straighten & micro-Micro polish all journals E31 head. Port work by Andrew Kazanis Dsi valves Diameter: 45/36.5mm Length: 118mm, titanium retainers. Isky springs. Bonk cam. Roughly stock exhaust and intake port sizes. Vapor honed inside and out. Rebello JE Eagle pistons and toyota rods 221 CFM flow at .45-.5 lift. Mine is 88.5x88.5x.25x3.14159x 84.6x6 /1000 = 3122cc It is showing off my intake design and Efi throttle bodies as well as a bunch of my small parts.2 points

-

Hey Derek. Good to hear from ya. Yeah input a vfd on it. And it already has the variable speed feed. It also has the indexable cutters on the head. Which will be fine to start but im looking at switching over to a single pcd/cbn cutter. I might have to do a pulley change to get the sfm where it needs to be. But currently im waiting on a box to put the vfd and other electrical components in. Im putting it on the machine where the motor start switch ans box was.2 points

-

Have you rebuilt your L28E with forged pistons and H-beam rods? Lowered compression? In my opinion that's too much turbo for the unmodified S30 chassis and "supports 500 HP" sounds good - but is it? In an unstiffened early unibody Z - probably not. We saw a 300HP RB25 swapped Z here in Phoenix tear the spot welds apart. It was a 240Z chassis and the 280 is a bit beefier but still. This is a town with no rust. The kit looks legit however (I'd still go for a different turbo, but that's me). I'm not a fan of the charge pipe config that an opposite-side intercooler requires but it's a little more difficult to get same-side charge piping through the radiator core support. Don't get me wrong, I'm in the TURBO EVERYTHING camp - but do your research, and do it the right way, and you'll have a Z that's FUN to drive and will stay together while you're doing it.2 points

-

2 points

-

I did a 14 gallon radium cell in mine because i plan on possibly running e85 and we have some 30-35 minute sessions with some clubs. I have it raised like an inch and a half out of the floor to make the bottom height where I was visually happy. My cell is advertised at 11.7" tall so if the ATL 10 or 12 is shorter then flush with the floor should be perfect.2 points

-

11-26-2025. I got the rear tires mounted on the wheels and balanced, and I was able to attach one headlight bucket and then started painting several coats of filler primer for deep scratches. The bucket has deep scratches in the metal in the bottom of the scoop portion, so this will get a start on filling them, and then I will put some glaze on there and sand it smooth and sealer prime it before color and clear. The other headlight bucket, after sandblasting revealed a crease in it, and I don't have the moxie to want to fight and fix a crease and make it look good, so I ordered up a reproduction bucket. I then got a call from J&S Polishing, and ran down there and picked up my intake and valve cover. Pics heavy.2 points

-

Time to update the build threat again. Things are moving slow at the moment but none the less progress is being made. I have contact with two local body shops in the area for the frame rail repair and to measure the body to see if it’s twisted in any way. One of the body shops is specialized is classic car repair and restauration but will probably be quite expensive but none the less a representative will come by to look at the car this week. The other body shop is a more generic one that also does a lot of classic BMW’s and has done some paint work for me in the past. There hourly rate is a lot cheaper, I know they deliver great work and I know they sometimes are willing to do cash work. To save money on the body shop hours I decided to bite the bullet and order a bunch of parts from Apex Engineered which should arrive somewhere next week. Deciding what to buy was quite difficult as the shipping rate varied a lot but in the End I got the shipping down to $284. I all I bought the frame rails, front fender braces, front and rear control arms, steering knuckles, front crossmember and the rear strut brace. As importing stuff from the US is pretty expensive I decided to place a bigger order then what I strictly needed to maximize the value for my money. As the car needed to get welded anyway I ordered the front fender braces as well to reinforce the front of the car as they weren’t that expensive and seemed to me as a worth wile upgrade. As for the control arms my main reasons for buying those was to delay any major body repairs. If my body turns out to be twisted repairing it would turn into a full on restauration project. I do plan on restoring and repainting the car some day but not now, so as a temporary solution the adjustable control arms allow me to tune the effects of a twisted body out a bit. At some point I would like to get the full Apex Engineered Retro Mod suspension so this will give me a great starting point to work from anyway. To save some more money at the body shop I will strip down the interior and remove the fuel lines myself before sending the car of for welding. But before doing that I still have a chance to fix some small stuff surrounding the engine. My backorder from Zservices in France finally came in together with a used Bosch AAR from a Porsche 944 as my original AAR turned out to be broken. So last week I took the valve cover off to adjust the valves and replace the gasket as it was leaking a lot of oil. Good thing I did as the valves where very out of spec. The adjusters where a pain to get loose but after that adjusting them was very easy. I put everything back together with some new NGK spark plug wires and started her back up. Even with near freezing conditions the car started right up and idled better then ever before. The engine still runs very rich at idle and I suspect it might be an injector issue but other then that the engine runs great and the emissions are within the limits so I will place that issue on hold for now. My plans for the coming weeks are to strip down the interior, remove the fuel lines, front fenders and doors. This will also give me the opportunity to clean and inspect those parts of the car for more hidden surprises. I will also repaint the fuel lines as they are full of undercoating and try to restore the dashboard as with any Z mine is cracked. As for the doors I want to rebuild the door hinges and maybe try and reupholster the door cards as mine are actually of a 2+2 and have a giant hole instead of a second door latch. I’m hoping to get the car back on the road after this so I can finally start to enjoy my 280z this spring. Video van WhatsApp op 2025-11-24 om 10.58.36_fab92d46.mp42 points

-

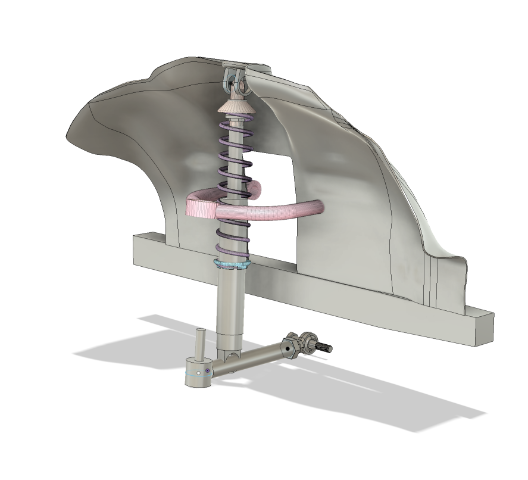

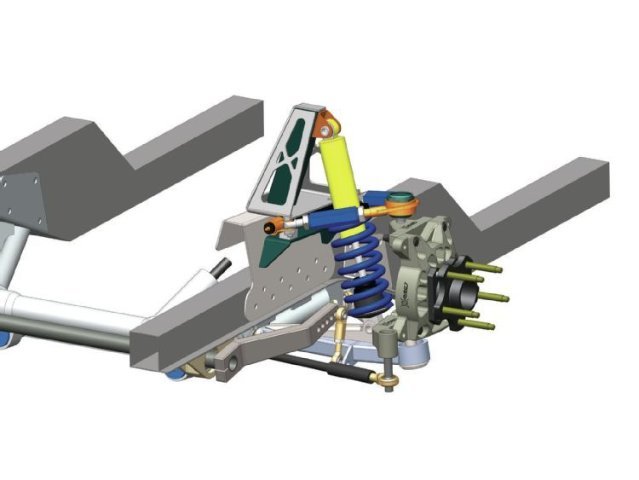

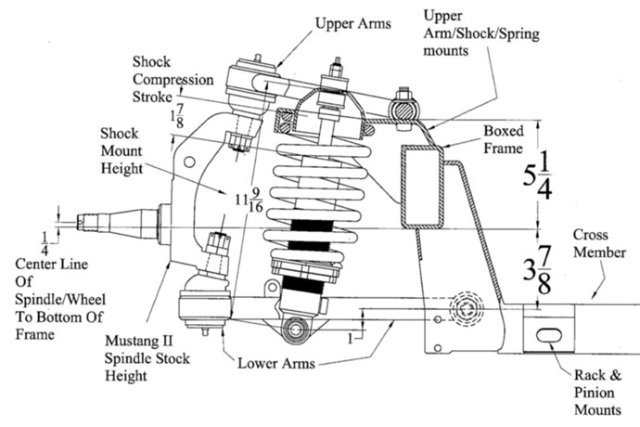

Hi HybridZ, Some of you have already seen my Apex Engineered Track Attack information/discussion thread here, I've decided after reviewing the design of the Apex Engineered front suspension kit, the best solution moving forward is to design my own. In this thread I will be documenting my progress and hopefully gaining knowledge on suspension design from you guys (or from what's left, f**k Facebook groups). To start... Why don't you just use the AE kit? It was $4000, you're just gonna waste $4000??? (Yes) Not enough shock travel, that's pretty much it. Once I received the shocks from Viking I realized immediately that 3.20" of stroke was not going to be enough and thus set out on a fool's errand to find alternative solutions. Viking shocks, from what I've found, have the most shock travel per the physical dimensions of the shock that I've seen so far. They're compact and the adjustment knob is well-designed to take the least amount of space with respect to the rest of the shock body. Very nice, but I will ultimately use either JRi's Mod series DA shocks or Penske's 7800/8300 series DA shocks as now, getting a shock long enough to reach between the strut tower and the LCA is more important. Design (pictured with 17" diameter wheel) The most prominent feature of my SLA design is the UCA pickup being located within the engine bay. The shock tower must be cut and a box structure is welded to the frame rail. This design is based on both the Maier Mod 2 design and Cortex Racing SLA kit seen here: Maier SLA Design Cortex SLA Design The reason I moved the chassis pickup for the UCA inboard was to extend the length of the control arm which should allow for a more compliant spring than the offerings from Apex. Mike Maier inferred the reason for the obscenely high rates was to keep the super short UCA from camming over and ruining the geometry. Fine for a super stiff autocross car but for a road-course car with kerbs, burms, and undulations in the track surface? Unacceptable. With this shock, I'll be looking at around 7-8" of total shock stroke travel. The remaining part of the design lies with the spindle (not shown) and the boxed-structure (also not shown). The boxed-structure was fairly straightforward to design - shout out to @Ben280 for sending me frame rail measurements while my car's been at the body shop. The boxed structure welds to the chassis frame rail located in the engine bay which the cross-shafts then mount to. The spindle is obviously not straight forward, fortunately for me there's plenty of resources on the LocostUSA forums for me to look at as well as Chassis Design and Race Car Vehicle Dynamics by Milliken and Milliken. Once the completed version 1 of the design is done, I’ll begin FEA with a safety factor of 1.15-2.00 at some lateral load to make sure everything should work without buckling. Until then, I have two separate designs, one utilizing Mustang II style cross-shaft mounting structures and one using Maier’s. The main difference being the orientation of the cross-shaft mounting bolts to the boxed-structure with the Mustang II’s bolts facing down, and Maier’s facing sideways. With the bolts facing sideways relative to the longitudinal axis of the chassis, side load is transmitted into the boxed structure through the bolts on their axial axis as opposed to their shear axis. Bolts do not like shear, however the Mustang II design is insanely popular so I suppose I could be overthinking this. Maier Cross Shaft Mounting Design Cortex/Mustang II Cross Shaft Mounting Design Methodology Starting with a 3D scan of the 240z that I re-topologized into ~10000 quads, I modeled an accurate-enough solid body of the fender well and shock tower. From there, I (roughly) modeled the Apex Engineered LCA (will probably try to use the T3 ones I currently have installed on the car as they are boxed structures), the Penske 8300 coilover at ride height, and upper control arm. You may have noticed the bottom of the shock clipping into the LCA, please ignore that, you didn't see that. In regards to swaybars, I will try to get the OEM sway bar design to work with my suspension, however due to the bottom of the shock being mounted on the LCA roughly where the swaybar links, this may be difficult to engineer. I could copy Maier’s LCA design, using a bent-tubular lower arm picture here: Moving forward, it might be easier to design my own boxed structure and try to mount a blade-style sway bar instead. Procurement While there's going to be a lot of custom laser cut metal from SendCutSend, I wanted to keep this kit as OTS as possible. I am not particularly interested in spending buku-bucks on one-off billet parts nor am I keen on dipping my feet into scaled automotive aftermarket product design & manufacturing. That being said, the spindles will likely need to be entirely custom if I can't find an alternative OTS. If I can find an upright on the market that fits my criteria I will definitely go for that, I’m trying to avoid using a Mustang 2 spindle as its shorter than I’d like it to be and completely wastes my steering knuckles and 370z spindles supplied from Apex Engineered (though steering knuckles and spindles are relatively cheap). Next Steps The complete version 1 of this design will be complete soon. Once I've finished my spindle and boxed structures the real work starts, articulating the design through all of its axes of rotation and movement will reveal conditions of binding and the dynamic geometries of the suspension. I started work on this project about a week or two after I placed my order for Apex Engineered SLA kit and have been doing it in my free time which is quite difficult to come by. God willing I shall endure.2 points

-

I don't know how you have the engine placed, but I would offset the engine about 1 inch toward the passenger side. The drive shaft angle is easier to minimize with the engine shifted in-line with the pinion. This also makes the weight distribution a little better when you are in the car.2 points

-

Just looking at the picture that you posted of your steering shaft, it looks like the u-joints aren't phased correctly. It may be an optical illusion from the angle of the picture.2 points

-

When are you hoping to get this car on track? I'm hoping to do an SCCA track day at Sebring in February. It would be nice to see you guys there.2 points

-

So after doing a valve adjustment my ITBS did sync up better . I guess I will have to keep an eye on that. I took out most of the injector trims and my afrs between the banks paired up better -especially at light cruise . I also worked out linkage issues I was having. You get no instructions with this kit and there was adjustments that I could have done better like the main rod-the only rod-to bellcrank. I didnt have it pulling the linkage in a straight line. Also found the linkage on the side of the ITB loose . This caused the linkage to rub against the body of the ITB. I got all this sorted right before ZCON . It was 4.5 hours to Nashville on smooth highway. 80 mph is where she likes to cruise . AFR's were around 15 on flat ground. No issues on the round trip. Got some great compliments from Peter Brock on my airbox . Cold idle is still 650rpm and about 800rpm when hot . AFRs at idle are normally around 13.1 Now to move on to IAC . I gave up on it right before I left .2 points

-

Hi HybridZ, its been a while. Took a long sabbatical from working on my S30 to finish college and get a job. For the last 6 or so months its been full steam ahead, the project is currently being rust repaired at a local body shop and I've been collecting parts as budget allows. The first piece major piece of hardware to arrived is the Viking Performance Shocks from the Apex Engineered Track Attack Front/Rear Suspension kit. I noticed that Apex’s website lacks details on shock and spring selection, so I’m documenting my findings here for others and to start a discussion on their choices. What's Included: Box as it arrives from Viking Performance Serial Numbers of each of the shocks (PN: C203) Viking Performance Shocks Link Part Numbers of Springs (600# & 700#) Initial Impressions: The car will be caged and used primarily/almost exclusively on track, so a stiffer setup is expected. However the spring rate selection still raises some concerns: The S30 chassis doesn’t benefit significantly from extremely high spring rates, even with a roll cage. The rear suspension uses inboard cantilevered shocks, which traditionally increase effective spring rate via the lever arm. This spring selection guide from Viking Performance indicates that the spring rate for a car with IRS and axle weights of ~1200-1400# is a lot lower than the supplied springs. I'm hypothesizing that the high rates were chosen to prevent the shocks, which are short to fit the Z’s narrow frame and tight packaging within the front wheel wells, from bottoming out. I’ve reached out to Apex Engineered to clarify the wheel rates for this setup and will update this thread when I hear back. Let me know if any of you have run this kit or high wheel rates.2 points

-

2 points

-

Those hairline rotor cracks are common when running giant rotors. Even though you are getting very little rotor wear due to the size of the brakes, the heat cycling eventually forms the cracks. I've ran them on track probably about twice as bad as your pictures.2 points

-

Got the front wildwood brakes installed today! A couple small quirks along the way on my install: First side I installed the rotor on the adapter ring to the hub wrong and the caliper didn't line up. It has two separate mating surfaces, one for a 240z and one for the later 280z hubs. Since I've replaced my 280z hubs with the T3 hubs, I failed to realize they're essentially a universal hub for early and late models which is why they had an extra shim ring of about 10mm to account for where the 280z mounting surface is. I took the ring off, so technically I had to install them where the 240z ones are, unless I wanted to run my rotor ring AND the hub spacer shim that they came with. Avoiding too many unnecessary pieces so I redid that side to mount on the 240z mating surface of the adapter and we were fine. Problem 2 - because I ordered the 280z brake kit, the included hardware also assumes you're still using stock 280z hubs. It's on and worked on my short drive, but I noticed in the picture where they're installed that the bolts don't go all the way out to the mating surface for the wheels. Quite a few threads left unengaged. It's probably safe for the time being, since I thought about the forces on those specific bolts and it's not really in or out since they're perpendicular to the rotational force applied by the brakes. I also didn't feel like I had particularly few threads engaged as I was bolting the rotor to the hub. Probably safe for casual driving, but it's a high priority fix right now to get the correct length bolts from T3 or locally. Better safe than sorry! Other than that I'm really happy. Bled the system with my new Motul brake fluid, which should cope much better with the heat off the turbo vs the cheap generic O'Reilly fluid I had before.2 points

-

This is the most activity this thread has seen in years, ANOTHER WEEKEND UPDATE! Got the intake welded up, some gasketing on the radiator extractor, and got the car back on the ground. Also got a nut and bolt done on the car. I still need to bleed the brakes, and do a quick fluid check and I'll be in good shape for a few events!2 points

-

2 points

-

2 points

-

Let that ship sail! Find another decent body for a few grand and save yourself a ton of time and money. I've seen many "resto plans" dye on the vine after the joy has passed, months and years go by and the person doing it burns out. Just my ywo cents!! Good luck.2 points

-

Looking again at the pics.....if you don't want to dip it, no sense in really even trying to restore it. It needs it so desperately, you should do it, or just find another Z car IMHO.2 points

-

yeah, Bad Dogs I hear are good, and that you can put them over the factory ones, but if the factory ones are rusty, then they need to be repaired/patched first or removed and replaced with these. I I think they way blok did his with thick heavy steel is probably the ultimate (the youtube link I posted earlier).2 points

.jpg.9a495c827ef23eaabc1d5953ebb2a222.jpg)

.jpg.a28119b0a846d3cc307ea2f488edf719.jpg)

.jpg.9342f7c8ede52da0e23921e7d8cf589c.jpg)