-

Posts

2391 -

Joined

-

Last visited

-

Days Won

35

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Miles

-

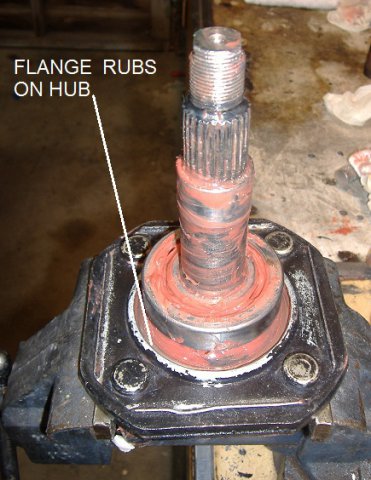

Stub Axle Flange Rubbing on the Face of the Hub (Bearing Carrier)

Miles replied to Miles's topic in Drivetrain

NewZed I saw John's post. I wonder if placing a 0.5 mm shimm between the outer bearing and where it seats on the shaft would work? I may just stop screwing with this and replace the strut. Not looking forward to that since springs, shocks, bushings have all been installed. Thanks -

Stub Axle Flange Rubbing on the Face of the Hub (Bearing Carrier)

Miles replied to Miles's topic in Drivetrain

I'll put the rotor back on and check it with a dial indicator. If the axle flange is bent I'll have to find a good used one as Nissan no longer stocks them. When I replaced the axle shafts in 09 I thought "ok that should last another 40 years. -

Stub Axle Flange Rubbing on the Face of the Hub (Bearing Carrier)

Miles posted a topic in Drivetrain

240Z with MM 240SX rear caliper install. Installed 2009. No problems unti the last year. While chasing a problem with an over heating 240SX caliper install on my 240Z I noticed that there was a lot of lateral slop in the stub axle. No bearing noise just lateral slop. I also noticed that in turning the axle there was a point at which there was some resistance. I didn't expect this as I had installed new OEM axle shafts, seals and bearings about seven years ago and the car only sees street use. I went ahead and replaced the inner and outer bearings. I torqued the retaining nut to 123 ft/lb as per factory specs when the copper washer is in place. Adding more torque has no effect on the rubbing. The lateral slop is gone, but the on and off dargging/rubbing is still present when the shaft is turned. Makes me think that the flange on the axle shaft is bent. Inspection of the inner side of the flange shows a circular witness mark where the flange is rubbing on the outer face of the hub (bearing carrier). See pictures. -

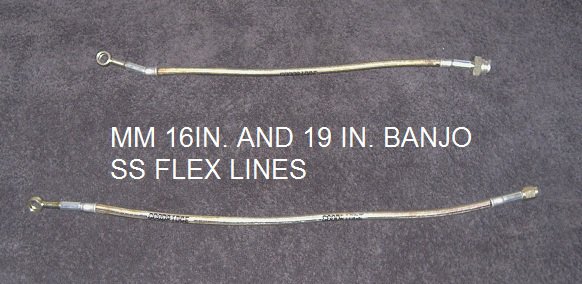

First study how the MM 240SX caliper install is done. Many posts on the subject. Install Earl's 10mm x 1.0 metric to AN adaptors on the ends of your hard lines where the hoses connect. This will allow you to use -3 AN SS flex lines that are available in a variety of lengths and connector configurations. Depending how you want to configure the flex lines you will need: Hard line metric to -3 AN adaptor fittings (10mm x 1.0mm inverted flare). Depending on how you plumb things you may need male and/or female hard line adaptors. Be sure they are inverted flare. -3 SS hose of the correct length. Allow for full extension on the suspension. Move the suspension though full range of motion to make sure the SS lines don't get pinched, rubbed or over extended. Hose ends of your choice: banjo, streight, swivel, elbo etc. Depending on the hose end you may need to buy -3 AN to 10mm x 1.0mm caliper adaptor fittings. or Use premade 10mm x 1.0mm -3 SS lines with banjo fittings as in the MM kit (See picture). Note that male and female -3 AN to 10mm x 1.0 metric adaptors are required. MM used Goodridge brand flex lines. Earl's has the banjo flex lines. Recommend that you continue searching in the brake section as there have been many discussions about plumbing options for the 240SX caliper install and how to configure AN lines. Earl's: http://www.holley.com/Index.asp?division=Earls

-

running rich and misfiring?!

Miles replied to datsundrifter's topic in S30 Series - 240z, 260z, 280z

Covered many times. Do a search for "rich". Search'n https://www.youtube.com/watch?v=yxEODjxaIfM -

Where to get brake hard lines??

Miles replied to stony's topic in Brakes, Wheels, Suspension and Chassis

Parts wanted. Pick n Pull. -

Where to get brake hard lines??

Miles replied to stony's topic in Brakes, Wheels, Suspension and Chassis

I put Viagra in my flex hose. Make your own using this: http://www.jegs.com/p/Eastwood/Eastwood-Professional-Brake-Tubing-Flaring-Tool/1330564/10002/-1 http://www.eastwood.com/professional-brake-tubing-flaring-tool.html -

There are several threads in the brake and brake FAQ forums that explain, in detail, several booster swaps including this one.

-

Hood vent solution: http://www.thezstore.com/page/TZS/PROD/30-7099

-

I am having the same problem. I replaced the bearings and stub axles with OEM Nissan parts seven years ago and now the right rear wheel bearing has a lot of slack when grabbing at the 12 and 6 o'clock points on the wheel. The wheels spins free. The brakes on this wheel also get hot. Seems like new OEM bearings should last another 40 years.

-

Good format to follow. Kind of like Consumer reports.

-

Surveys work best if people have a set list of criteria and structure to respond to. Otherwise the survey will drift off course. For example: Rate: 1 - 10 1 = worst 10 = excellent Cold Bite: Dusting: Fade: Stopping Peformance cold: Stopping performance hot: Street performance: Etc. Other Comments. Members can copy your list of criteria into their response and fill in the information for each item in the list.

-

New- Please answer some of my questions

Miles replied to KaiEstrada's topic in S30 Series - 240z, 260z, 280z

Study HybridZ in detail for at least 100 hours and then ask specific questions. Otherwise your questions will be ignored. Read all of the new member stickies. -

Sell the car.

- 48 replies

-

- brake bleeding

- bleed

-

(and 2 more)

Tagged with:

-

Inconsistant Brake Pedal Feel

Miles replied to WRC17's topic in Brakes, Wheels, Suspension and Chassis

Second bad MC. -

For your own safety I recommend that you take the car to a brake shop and let them sort things out for you. You are not going to solve the problems on-line.

- 48 replies

-

- brake bleeding

- bleed

-

(and 2 more)

Tagged with:

-

Here are a couple of brake diagnosis flow charts that may help isolate the problems you are having. Make a check list and go back through your brake system part by part and take notes. Be methodical. Check off each item as you complete them. Here are some things that may help: Verify that the MC is properly bench bled and that it holds pressure (plug outllets with 10mm x 1.0mm plugs and push the MC piston) Verify that after you checked for the reaction disk that it did not fall out while you were doing things to the MC. It happens. If you have not done so, use JB weld and glue the reaction disk to the push rod. No more worrying if it fell out. Adjust the MC push rod to where it almost touches the bottom of the cup it sits in. You can just pull the MC off the booster leaving the hard lines connected and push it aside while you adjust the push rod. Test fit the MC and adjust the rod out until you feel the MC spring back and then keep adjusting the rod inward and fitting the MC until the MC no longer springs back. Test drive to make sure the rod is not too far out which will cause your brakes to drag and lock up. It is easy to adjust the push rod if you have cleaned and lubricated the threads on the push rod. When installing a bench bled MC, block the ouput ports with rubber plugs to eliminate fluid leaking out and air getting back inside while installing it. Also, block the tank openings with large rubber stoppers to keep fluid from flowing anytime you have a line open or installing the MC. Use a Motive Power pressure bleeder pumped up to about 20psi and flip/move/shake/tap the rear calipers in all possible positions while fluid is flowing. There are a number of places inside the caliper where air can get trapped. Go here for the Motive Power Bleeder: http://www.motiveproducts.com/ Of course verify that the fronts are completely bled after installing the MC. After verifying all air is out of the system with the Motive Power bleeder install Earls Solo bleed screws (spring loaded valves) in your MC and calipers. Why? because the power bleeder flows better with the stock bleed screws and the Earls solo bleeders will make future brake work much easier. Don't use the crappy solo bleeders ( Russell) that use sealent on the threads. If you do not have the reaction disk in place and the push rod properly adjusted your brakes will feel soft with a long pedal which will make you think that there is still air in the lines. Welcome to the 10 gallen brake fluid club.

- 48 replies

-

- brake bleeding

- bleed

-

(and 2 more)

Tagged with:

-

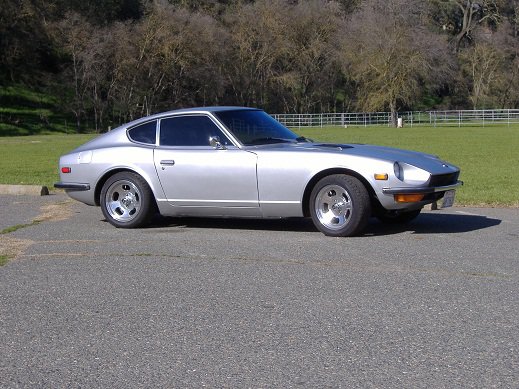

Full coverage on my SBC 72 240Z from AAA. When an old woman backed into my Z at a stop light AAA replaced the left front fender, bumper, grill, paint etc with no questions asked.

-

Anyone know what wheels these are?

Miles replied to ThatOneZ's topic in Brakes, Wheels, Suspension and Chassis

Do a Google image search. Many hits. -

Anyone know what wheels these are?

Miles replied to ThatOneZ's topic in Brakes, Wheels, Suspension and Chassis

Did you look at the links in that thread? -

Anyone know what wheels these are?

Miles replied to ThatOneZ's topic in Brakes, Wheels, Suspension and Chassis

http://www.zcar.com/forum/10-70-83-tech-discussion-forum/324969-14-wire-wheels.html -