Search the Community

Showing results for tags 'Fuel'.

-

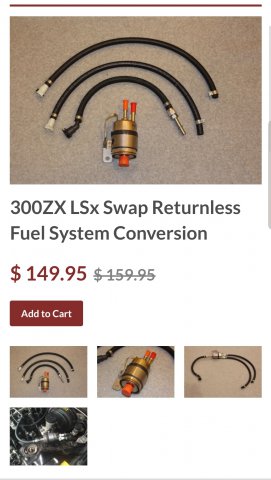

Hello! First post here, was wondering what everyone used for their fuel setup on their stock tanks. I have a '79 280zx with a 5.3 (l28 saved for a 280z), stuck on what way to get the ls fuel pump to the stock 280zx pickup tube in the tank. Would there be any safety issue if I use a kit like the one pictured and just clamp send/return from the tank directly to the Corvette style regulator, or would that work just fine? Any info would be great, thanks!

-

Hello everyone, i had a question regarding the sr20det swap into the s30 chassis more specifically a 280z. What needs to be done so that the egnine can get enough fuel for about 250-300 crank horsepower reiably? Getting a fuel cell isnt really an option since i plan to daily this car in the future. I was just curious what everyone else was using in terms of fueling in their ka/sr swaps.

-

I am looking go find suggestions on diag for a fuel issue with my 1977 280z. It's as if all 6 injectors are clogged (though highly unlikely). I have fuel pressure at the rail but I was thinking that the BCM could be the most viable answer (not commanding the injectors to fire) I have spark at every cylinder new pump and filters. Seasoned S30 mechanics any suggestions?? I don't have a lot of diag experience and appreciate any input (except the negative BS).

-

This is my first carburetor car and I am still getting rid of the intake and exhaust leak from the rear cylinders with a gasket I ordered. My issue now is the car runs fine at idle, but the second you take it down the road and try to get it moving the carbs seems to run out of fuel inside the bowl. My 260z has a filter athe bottom of the tank to electric pump, up the body to the engine bay into large cannister filter to vacuum mechanical fuel pump to dual Weber carbs. The 3-5 psi required by carbs I easy for the newish pump under the car now. I am thinking that the mechanical fuel pump cannister in the engine bay of my 260z should be bypassed by the electrical pump I have near the gas tank. I believe the fuel delivery is my issue with a engine that can be running the suddenly die after burning a bit of gas with a longer rev. When I'm able to I'll try to see if I can pressure test the system and see if it's better to bypass.

-

Got some gas bummed off me at the station. Sufficiently distracted, I drove off with the cap on the spoiler. Sucks to loose it after owning the car for four and a half years. I was doing so good. Needs to fit a '70. It doesn't need to be the "correct" one. I can handle the shipping by emailing the seller a FedEx label if desired. I get it the fastest/cheapest that way. I'll need box dimensions, weight and an address. PayPal would be nice, but I'll mail a check if I have to. Thanks! -Gonna chain the next one down...

-

Greetings from Montana. This is my first post so let me know if it's helpful. So my '75 Z has been sitting in a garage since 2013 on account of the clutch pedal lost its pressure and the fuel system was all gunked up with rust. I went off to school so I had no time to work on it. I came home this summer and have been working on it for a month or so now when I can afford it and have the time and finally this weekend it should drive once again! I came to the conclusion that the priority would be the gas tank and fuel system. So I dove right into draining the gas and stripping the tank from the car. What I had found next was a nightmare. Layers upon layers of rust in the gas tank! First thing I did was sloshed around quite a few nuts and bolts with some old gas and banged on it very carefully with a hammer to break some of those rust chips up. I drained what I could of the broken rust pieces and began my search for a cheap alternative for a rust removing chemical. Come to find out, white vinegar works wonders if you submerge and soak rusted metal for a couple days. I got 17 gallons of the stuff for 2$ a gallon at costco because you will want to fill the entire tank to prevent flash rusting on exposed metal. I filled the tank and sealed it all off with duct tape except for the small tube at the very top of the tank so it could breathe the fumes. I let it soak for 3 days like this and I would suggest placing whatever you are going to drain the vinegar into underneath the drain plug BEFORE you fill it because you won't be able to lift it yourself after it is full of 17 gallons, unless you are Hulk Hogan. Once you are satisfied with the amount of time it has soaked(anywhere from 24 hours for minor rust to 3-4 days for caked on rust), unscrew the drain plug and commence draining. After all but about a gallon or so has drained, grab hold of the tank and start rocking it back and forth and 360 degrees, slowly to get all the flakes to drain. You could bang on it with a rubber mallet or hammer again as well. Once it's all drained, take your phone camera and put it on video with the flash on and poke it inside the sending unit hole. You will be amazed looking around at how well the vinegar works. You will see mostly bare metal. Unplug all the holes and allow it to dry for a day or so. I taped an air compressor blower to one of the holes to give it a blow dry for about an hour right after I drained the vinegar. There will be flash rusting and there is nothing you can do to avoid that unless you wipe it clean with a rag right after it has drained, which is impossible with a gas tank. But don't worry the next step will cover that. Now go to your local car parts store and ask for a liquid gas tank liner, any brand will do. Make sure you read the directions and get enough, especially if you want to do 2 coats. They usually come in 1 quart cans that will usually only cover about 12 gallons. The brand I got was this way. For my '75 280z the gas tank is 17.2 gallons so I had to get 2 quarts. Once you are satisfied that your tank has dried completely, it is time to put your first coat on. Look inside your tank and you will see that it has a divider to the skinny part of the tank. For this reason, I plug all the holes except for the sending unit hole on the tall part of the tank and the gas outlet hole on the narrow part of the tank. This allows you to fill both halves without worry of missing a spot with the coat. You need a good funnel for this stuff. Fill the narrow half with one quart first because it takes longer. Then fill the sending unit half with the remaining quart. Plug the remaining holes. Very slowly roll the gas tank around in your arms 360 degrees on all planes for about 15 minutes or until you think every spot has been touched by the good stuff. It's kinda like the consistency of molasses and it dries like a rubber glove so be thorough. After rocking it around on all planes I would let it sit on it's bottom for 5 minutes then on it's side for 5 minutes then on it's top for 5 minutes then on the other side for 5 minutes and back again on the bottom. I did this for an hour or so while I was changing the oil. I wanted to make sure that bare metal would not show. Once you are satisfied, place it on top of some saw horses or an old cooler or something and place one of the liner cans under the drain plug and unscrew it. Remove all plugs so it can dry evenly. On all the small openings, I took my air blower and blew a small amount of air through to make sure the liner didn't plug them. I would highly recommend this. Let it dry for a day. Come back and check to see if it dried evenly. If there are bare spots, do a second coat, if you have enough left over liner. I did anyway. Let it dry for a day and a half just to be safe. This next step isn't necessary but I recommend doing it since you already have the hunk of junk out. Get a can of rust proof spray enamel from your hardware or car parts store. You could get any color you want. I just got black cause I don't know what the paint job will be on the car yet. Tape all the holes, Air blow it free of debris and sand the rusty spots, air blow again, then commence spraying the enamel. Let it dry. Now that the gas tank is complete, check all your filters. My Z had a small filter between the outlet and the fuel pump. When I took it out, it was pack full of rust to the brim. I have looked all over the market and can not find a part to replace this filter. I tapped all of it out and submerged it in vinegar as well. There is a strainer between the fuel pump and the fuel line to the block. I removed that and soaked it in vinegar. I installed a new fuel pump while I had the gas tank out. And there is another larger fuel filter by the engine block under the hood. I just got a new one of those for 20$ and installed it. Once your tank is completely dry, put it all back together. I suppose you could seafoam the system and bleed it if you want to go a step farther. I probably won't since I know the gas tank is good and that is the source of bad gas. I figure any bad stuff that remains will get washed out and burned off in a day of driving. Thanks for reading my first post! Hope it helped!

-

I was wondering if someone could tell me how to test my fuel pump relay with a multimeter? I was driving last night and my car started sputtering and running really lean and eventually just died. It would start and idle choppy until i pressed on the gas killing it. This morning when I went to go call a tow I noticed that it now only starts and immediately dies afterwards even with a jump.

-

From the album: The Restoration

After I had got rid of rust and applied liner -

From the album: The Restoration

-

Hello, Can anyone smarter than me take a look at this tune and tell me what is wrong with it for my build. I have a pretty much stock 82 l28et stock injectors DIY wiring harness i put together. iac sensor 240sx 65mm throttle body and tps DIY trigger wheel single coil lc2 wideband (not wired to ms2) walbro 255 lph inline fuel pump no other sensors are connected to the MS2 Ive been messing around with some other peoples tunes and came up with this. This started the previously warm car yesterday and i set my timing on the car with this project. its set to around 19 btdc because it was running so rough. The car was running very rich and was backfiring with every change in throttle. i assume the ignition settings might be wrong and the fuel map is too rich. ive scaled down the fuel map and it didnt seem to change much at all. could their possibly be other more hidden settings that i also have to change. Today i tried to start it and it just kept flooding itself no matter what spark settings i change or if i scale down the fuel map. Im new to this type of stuff so any help is apreciated. ive been researching so much and tried so many things but nothing is working. thankyou.

- 83 replies

-

- megasquirt

- ems

- (and 5 more)

-

I'm experiencing a slight rich issue and need the groups help. Its an l28et running a JWT 550 kit in a 71 240z. Using the stock l28et fuel rail, Aeromotive FPR with psi gauge, upgraded to bigger fuel line (still using the oem return line), and an unknown in tank pump. Prior owner says its a 300zx turbo pump, but I have yet to drop the tank. I have seen it go to 65 psi with no pressure drop at all. 11.5 AFR until boost crosses the 10 psi mark, then fuel pressure shoots up 5 psi too much (relative to boost )and stays that way. At idle, fuel psi is correct. Cruising, it's correct. The problem shows up only after 10 psi of boost, thats when my AFR's go to 9.5-10.5. Myself and other can't see any smoke from the tail pipe during acceleration. I believe there is an restriction thats not allowing the fuel to return fast enough. Maybe the oem fuel rail? I don't see any pinches in the rail that would cause such a thing. Maybe its my setup. Any ideas where the restriction might be?

- 57 replies

-

- fpr

- fuel lines

-

(and 6 more)

Tagged with:

-

I just bought a 1975 Datusn 280z and i drove it home. It ran well beside the exhaust leak that i will be attempting to fix in the future. I took off the front and rear bumpers first thing. I had to remove the gas tank to remove the rear bumper shocks. After reinstalling the tank, i put some gas in for a total of around 3 gallons. The engine took a while to start and ran kind of crappy so i thought it might need more fuel so i put 2.5 gallons more in. It started and idled fine so i figured it i would drive to gas station to fill up. less than a 1/4 mile from house it started cutting out on me. I started to turn around and it died a few times before I got it back home. I put 2.5 gallons more in the next day and it would idle fine for a long time but still cut out when i tried driving it once it got to higher rpm. I cleaned out the fuel filter and then it ran good for about 3 or 4 high rpm pulls before it started to cut out again. this time it started to idle kind of crappy too. Anyone have any advice? it never cuts out at high rpm when idling though, its just under load. Any help would be greatly appreciated.

-

I obtained a pre...umm, "hybridized"? '75 280z fairly recently and, having swapped the tranny and done a bunch of other stuff, I'm now trying to tackle a fuel starvation issue. The previous owner installed a very generic Mr. Gasket 12S fuel pump in the engine bay (apparently 4-7 PSI.) This has caused me some fuel starvation and vaporlock issues. The stock mechanical pump on my engine (1970 SBC 350) is apparently not an option, both per the JTR conversion manual, as well as my own experimentation. What have you folks used in the way of fuel pumps? The JTR manual says to mount near the gas tank, but it doesn't mention brand or capacity for an SBC 350...

-

Guys, I'm still trying to get to my first drive after a long build. Last week I had an electrical issue that a few of you posted replies, and "rsicard" identified the issue. Thanks to everyone. So now electrical issues are behind me, I think. And I'm having a fuel delivery issue. The stock '77 280Z fuel pump is supposed to be good enough for TPI according to the JTR EFI book, but if I read between the lines I think it is marginal. No matter, my stock pump developed a slight leak between the halves of the fuel pump body, so a few weeks ago, I replaced it with a new 280Z pump "Airtex E8312" from Autozone. After getting the timing close (more work to do there later) it idles smoothly and pressure (measured at the shrader valve) stays between 35-40 PSI at idle. But as soon as I tip in the throttle, the pressure starts dropping until it dies at or below 25 PSI. Even if I try to go back to idle, once the pressure starts dropping, it can't seem to recover. No matter how careful I am, and I'm talking about barely 2000-2200 RPM, I seem to get fuel starvation. I talked to the parts house, and the Airtex E3210 is the replacement 5.7L Camaro pump, which is rated at the same max. pressure, 5 PSI less minimum pressure, but about 40% more flow rate. Flow rate sounds like my problem. However, the E3210 is an in-tank pump that won't physically mount like the external Datsun pump without modifications. I'd like to avoid all the mods to go in-tank if its possible. I didn't find anything in the FAQs, so what have you guys found as the best/right pump for this combination? Thanks, Steve And for those of you that keep requesting pictures, I will be posting them soon for anyone interested in this combination, my suspension mods, my Vintage Air AC install, or anything else of interest.

- 6 replies

-

- fuel

- electrical

-

(and 1 more)

Tagged with:

-

Hi guys, here's where I'm at- I'm trying to get underway on a v8 swap into my '73 240z. Car will be for street use/getting into trouble- nothing serious like autoX/track/drag. My plans are as follows: Chevy 350 engine 650cfm vac secondary carb MSD 6al ign Camaro t5 trans Custom driveshaft JTR engine/trans mounting kit JTR headers (maybe) Custom exhaust Upgraded fuel pump OEM radiator from v8 car I have been doing a ton of reading and already ordered the JTR manual but still have a few logistical questions. I found a good candidate for a motor, BUT it is a truck vortec motor. I've read there are 2 main types of flywheels- 153 & 168 tooth. Don't know which one this engine has. Since I plan on using a camaro T5 (I know these get a bad rap, but I think for a mostly stock 350 I should be ok if I don't abuse it?) I'm not sure about fitment. So, first question, 1) what kind of fitment issues should i be thinking about? As long as the flywheel is the right diameter it should just bolt up? My z is carb'd and this engine ill be too. So, second question, 2) Do you think my fuel system can flow enough for a 350? It has a return line so I'm assuming the pump isn't close to max capacity right now, which is why i wasn't sure if an upgrade would be necessary since i'm staying carb'd. I have a couple more, but lets start with these and hopefully reading the manual should answer most of them. Mostly stumped on the t5 trans fitment to what other engines. I've been reading a lot on hot rod forums but haven't exactly found an answer. Thanks, Adrian

-

Hi Everyone, I read many posts in the archives and lots of Google searches but I would love your advice on my specific case. I have a '78 unrestored 280Z that used to run like a charm and I'm not getting rough startup and probably heat problems? I am pretty noobish with mechanic (learning from 0) so bare with me. Symptoms: A vast majority of the time, the car will 'cough' a lot at startup and runs rough for about 5 to 10 seconds. I'm usually flooring it for a split second during ignition to avoid stalling and then gently rev til the engine runs smoother. I feel like the problem occurs more when the outside temperature is very hot (I live in SoCal), however my car is garaged and the problem also occurs in the morning. The car seems to run better warm and if I stop it after driving it for a couple mile and restart it in the next 10 minutes it will fire right away (like even faster than modern cars, I just push the starter and boom! When that happens I feel almost suspicious of how fast it starts). Finally, I had a problem 2 times. The car stalled after a few miles (usually hot day and driving a bit sporty). It stalls and doesn't turn back on. I had to push it to the side of the road and let it sit for 10-20 minutes before it'd start again. I changed sparks, fuel filter, ignition coil. Any advices appreciated. Stuff that I could check myself would be even better (keep in mind I'm a noob) Thanks a lot, M.

-

Hello all! I know this is a lot to read, but I am trying to be thorough and give as much info as possible. If you don’t want to read it all, you can skip to the last few sections and get the general idea of my current issue that I need help with. Thanks in advance! First, a little about me/the car: I have worked on cars for about 13 years now. I don’t consider myself a pro, but I consider myself fairly knowledgeable when it comes to cars. I have rebuild motors, help friends restore cars, done motor swaps, and do all my own maintenance. However, I know that every car is different and comes with its own unique issues/methods, so there is always something to learn. I bought a 76 280Z about a year ago and have been slowly fixing it up. This is my first Z so I knew it was going to be a learning experience (which is what I wanted) and so far I feel that I have done quite well with it. It was in pieces when I got it. The previous owner had blown the head gasket and had decided to take the opportunity to throw in a Chevy V8. He got as far as striping everything out of the engine bay and then decided he wasn’t interested. Luckily all the parts were there (albeit in many many boxes) so I decided to jump on it. I picked it up for cheap since it was an unassembled puzzle that needed some work. I decided to rebuild the stock L28 and put everything back in. I have completely dissassembled, cleaned, and powdercoated the suspension. There was a little rust in the usual places, but I have gone and cut out/fixed all of that. The interior was mostly bare and I have been working to fix it up. I will be posting up some pictures of the work before/afters of what has been done so far. This is in no way a full restoration project. The goal a solid project car that will be fairly reliable and I can drive every day if I want. I am trying to keep it a budget build so I have been doing all of the work myself (aside from machining the block and head). I am in the final stages of getting it back on the road, but have run into a big issue. Before I get into the issue, let it be known that I have had the FSM and FI Bible for it since day one and have been over them many times throughout the build. I have done searches on the forums but have only found one other post that had similar problems and so far, doing what that person did to fix the issue has not solved the issue on my car. I have tested just about everything I can using the FSM and FI Bible (and I will go into some more detail about that), but have been unable to solve my issue and I am ready to farm this out to the Z community for any suggestions and advice. The problem is as follows: When I first got the motor back in and everything hooked up, it would start fine and idle decently, but had a bad misfire under acceleration and once warmed up real good, would occasionally sputter and die at idle. The severity of the rough idle/acceleration seemed to vary quite a bit over the coming weeks trying to diagnose and fix the issue. I adjusted the ignition timing and it seemed to help a little but it did not completely solve the issue. I installed a fuel pressure gauge in line (was planning on doing that anyways) and it shows normal pressure as described in the FSM. I pulled the plugs (which are new) and they were covered in soot, so I know that it was running very rich. I figured that it could be sticky injectors (the only thing aside from the pump that I didn’t change in the fuel system) so I went ahead and swapped them all out. I was able to get a new set of Bosch injectors on a closeout price so it wasn’t a big expense and probably would have needed to be done anyways since the car sat for over a year. Still ran rough. In the past month or so (I have a very busy schedule during the summer so progress has been a bit slow) I have accumulated only a few miles from taking it up and down the driveway and around the block once to test out whatever adjustments I made. Currently the car will not start (yeah I know, you’ve heard it many times before in the “my car wont start please help me!!!” posts). It all started when I last took it down the road for a test and then after the motor was good and warmed up I turned it off. When I went to crank it up again after about 2 minutes it started briefly for about 5 seconds and then died. I cranked it again to try to start it and would get nothing. I popped the hood to have a look and saw fluid pouring out from near the radiator. I thought “crap, busted the coolant system”. I go forward to have a look and realize that it is fuel pouring out of the intake filter. You can imagine my alarm when I realize I have a ton of gas pouring out of a hot engine! I let the car cool down and started the process of evacuating the fuel out of the cylinders/intake. The car will no longer start at all, it will just immediately flood. On to what I have done to try to fix the current flooding issue: I searched the forums for stuff like “fuel coming out of the air filter” and was only able to find one really closely similar post, found here: http://www.classiczcars.com/topic/43951-1978-280z-fuel-pouring-from-throttle-body/ Reading through this lead me to the common “bad CSV” issue. I have since blocked off the CSV entirely and yet it still floods. I have hooked up a set of noid lights and cranked the motor (with fuel pump unplugged of course) to test that the injectors were getting a pulse from the ECU instead of being stuck on, and they were all fine. I tested the AFM directly with a multimeter and it checks out. I tested the main connector to the ECU and everything checked out within the specs lain out in the FI Bible with one possible exception. The page for “Air Flow Meter Fuel Pump Contacts” (page 53, Test #1-(5)). It says when the AFM flap is at rest there should be no continuity, and that when it is open there should be continuity. What it doesn’t say is whether or not this test should be done with the key off, or in the on position (some test state to have the ignition in the on position, while others do not). When I run this test with the key off, it checks out fine. But when I run the test with the key in the on position, I get continuity all the time regardless of flap position. If I understand the system correctly, this circuit is what keeps the fuel pump running when the engine is running, and shuts it off when the engine stops running. So to me, I would think that this test should still have no continuity with the flap at rest and the key in the on position. Is this correct? If so, I feel that it might be that the AFM is bad, but when I test the AFM directly with the multimeter, it seems fine. I just don’t want to start replacing very expensive items to diagnose. Clearly something has changed after the first time it flooded out because that is all it will do now. I was thinking maybe the first time it flooded, gas got into either the AFM or TPS or something, and is causing a short or false signal and telling the ECU to pulse longer than it should, or pulse at the wrong time. I opened up the ECU and it looks perfect (no bulging components, no burns, clean as a whistle). Since the last time it flooded, I have dried everything out and completely disassembled and cleaned the BCDD (which was full of fuel). I did a compression test again and so far it looks like no mechanical damage has been done as a result of flooding the motor a few times. I cant find anything wrong (and it could be that I am missing something), but I am reluctant to keep trying to start it because of the clear risk of causing mechanical damage if it keeps flooding. Sorry again for the extremely long post, and thank you very much if you took the time to read through it all and reply. I tried to be thorough, but in my long post may have left something out. If so, I apologize and will add info as requested. Any help or suggestions would be greatly appreciated! TO RECAP: The engine used to run, but misfired and was running very rich. One day it flooded out to the point of fuel dumping out of the intake and now that is all it will do. I have tested the AFM and ECU harness and as far as I can tell it all seems to be pretty good. Parts that are new are the injectors, ignition coil, plugs, FPR, fuel filter. I get spark, and fuel pressure is good. I have blocked off the CSV entirely, so it is safe to say that it isn’t what is dumping fuel into the intake. ECU looks good and I have tested each injector plug with a noid light and am getting a pulse. It could still be that the ECU is sending a longer pulse than it should, but I don’t have an extra ECU around to see if there is a difference.

-

Hey guys, I was searching the internet far and wide trying to find a figure for dead times on my injectors and I found a cool website that other people will probably find useful. http://injector-rehab.com/shop/lag.html These are probably not going to be exactly the same as your injectors, so if you're feeling adventurous you can measure your actual individual injector dead times using this page here: http://www.msextra.com/doc/ms3/injdeadtime.html Hope this helps somebody.

-

I'm rebuilding an l28et and noticed this injector looks off. At least the cap is missing, maybe more. Is it toast? I can't find anything to reference what it should look like without the cap. Thanks in advance. And a different injector for reference:

-

Hi im new to this forum but just the other day I got my first 280z. When I bought the car I knew it would be a project but I thought mechanically there was nothing wrong the previous owner swapped a new l28e and a new 5speed with 50k on both. With that being said I was doing a speed run the other day and after taking my z to 100 the power curve seemed shaky like after 80mph I would get bursts of highter power and then a lull of power. Now the problem hasgotten much worse, when I get upto 4000rpm it feels like the car is fuel cutting and randomly while I drive I just get what feels like complete fuel starvation. I think it might be either the afm or the tps but I was wonderin if anybody else has had this problem. There are new wires and plugs, new fuel filter, and injectors, and from what I can tell decent fuel pressure. I also started the car and it seemed like one of the cylenders want firing... maybe somethin to do with ignition timing? -thanks

-

Hello everyone, I recently took the engine out of my 280ZX to repaint the engine bay and replace some parts on the engine. I have the engine placed back in the car and the starter is working. It sounds like it wants to start when I put starter fluid in throttle body and I am getting fuel pressure before the pressure regulator on the fuel rail. I am not getting any fuel pressure on the other side though. Is there anything I can do or do I have to just replace the regulator.

-

Started to get a loss of fuel stall at high rpm with full throttle 3 weeks ago and assumed mechanical pump was going bad. I've been out of country for 2 weeks so when I returned I replace the fuel pump and get no fire at all. There is at least 3 gal in the tank and I have cleared all the lines but when I crank it over there's no fuel flowing into the filter and when I pulled the fuel line from the carb and crank I get no fuel as well. Grabbed the old pump and she work just fine by hand pump as well??? Why can't I pull fuel from the tank? Is it possible the cam lobe to actuate the pump lever is screwed up? Wouldn't that have been more catastrophic? I'm at a total loss. I could run the electric pump with mechanical omit but I'm not convinced that's the right choice until I know why I can't pull or push fuel. Any thoughts?

-

Hi everyone, I've been trying to get my car working properly again and it keeps giving me trouble. I think the source of this is the fuel line i'm using from the tank outlet to the fuel pump inlet. It's carburetor hose since it's on the non-pressurized side of the system, but it's very soft/malliable and kinks very easily. I think this is what's causing my car to not get enough fuel while driving. I can't find the OEM Nissan hose anywhere, and I can't find 7/16 fuel injection rated hose anywhere either. Does anyone know where I can get either of those? I'd like to get my car running again ASAP. Thanks, - Brandon

-

Hey everyone, I've got a 1976 S30. It's effectively stock as far as the EFI system goes, all I've done is change the plug wire connectors for the injectors and I've replaced the fuel send lines with new hose. Of course I also put a new filter on it after I got it as well. During the summer, it started having an issue where it would randomly lose engine power entirely for brief moments- a number of seconds, really. Then it would pick back up and drive normally. I thought it was just crud working its way through the lines from the gas tank and I wasn't too concerned about it. Shifting up a gear would usually make it stop. Then it started to bog down on the rare occasion. It would run rough, misfire, had no power, and wouldn't rev over 1500 rpm (or if it did, it went kicking and screaming). I would drive it for a minute and then it would start running normally. On my way to my first day at a new job last month, it died in my neighborhood and wouldn't start again. My dad and I were trying to push it back that night but it was tough since it was on a slight slope. He went to get the truck to pull it back and I decided to try starting it again to see what it would do. It caught a couple times and then finally coughed back to life. I changed the fuel pump thinking it was the old one going bad. I used an Airtex pump from O'Reilly (I know, you're probably rolling your eyes now) and installed a Fram G3 between the tank and the pump to keep tank crud from messing up the pump. It worked fine for a couple days and then the issue came back with a vengeance. As it sits now, the car idles fine. Driving it, it starts to stumble around 2500 rpm and the power cuts completely at ~3000 rpm. It's almost undriveable unless I'm really careful with how high I rev. Even then, it can be fussy. The general manager of the auto shop I work for knows the car really well so he helped me diagnose it on Saturday. He checked and adjusted the TPS and AFM. We tried a new computer since we had one laying around and there was no change. He checked for leaks on the intake and found none. He removed the vacuum from the FPR on the fuel rail and fuel pressure rose accordingly which, if I've read correctly, means that the FPR is functioning properly. The last thing we did was check fuel pressure (probably should have done that first but hindsight is always 20/20). It was running at 32 psi @ idle and under load (revving the car) it would dip to ~30 psi. If I'm correct about the FPR working properly, I've narrowed it down to 3 suspects: - The G3 filter I installed between the tank and the pump - The new pump - Fuel damper near the pump I read about people installing the G3 so I thought it was a good idea. The pump is new, but it is a random O'reilly brand. Since I was having issues before and after replacing the pump, that leads me to believe that the issue does not lie in the pump setup I installed. My old OEM pump was probably still working alright for its age. As I type this, the most plausible cause in my eyes would be the fuel damper. I'm not sure what the symptoms of a bad fuel damper are, however. Anyone have any suggestions? I'm going to try running it without the filter when I get the chance, but I've been obscenely busy the last few days. Thanks. Pac_Man

-

Hi Guys, I'm still pretty new to the forum but I wanted to start contributing right away! I just bought a 1975 280z that had been sitting for over 10 years and was the victim of seized fuel injectors. There are a couple of options on how to handle the situation, one would be to replace the old injectors with new ones. Thats a solid choice but oem injectors will set you back $350+. Another option would be to buy refurbished injectors. Again, that's a fine option, but since fuel injectors are sealed units that cannot be opened, all you are really buying are old injectors that have been cleaned. Your next choice is to send the injectors off to a fuel injector cleaning service that specializes in cleaning electronic fuel injectors. If you choose that route I'd suggest www.witchhunter.com as they are a well known and good company. A full service cleaning is going to set you back about $180 but has the added benefit of having the injectors flow tested. Lastly, you have the option to clean them yourself. The process I came up with worked great for me and only cost about $20 and as such I will be discussing my method for the remainder of this article. Before we start, a disclaimer: *** The procedure Outlined below was developed by myself to clean my bosch L-jetronic fuel injectors. I am not a professional, nor do I claim to be. By performing any of the actions described in this article you risk damage to your fuel injectors that could render them inoperable. This process may be used on any injector however take special note of the correct voltage used to drive your specific fuel injectors.***** The Injector: How & Why Let's take a brief look at how the injector works and why it may end up seized shut. First things first, take a look at this cutaway view of an injector: (photo credit Gordon from witchhunter.com) The points we are most concerned with from this photo are numbered 4, 5, and 6. Number 4 is the coil. It is a coil of wire that wraps around the inside of the injector body. When current is sent through this coil, it creates and electromagnetic field, basically, it's an electromagnet. Number 5 is the pintle. Think of it as the rubber stopper that plugs the drain in your bathtub. It is a tiny piece of metal that for al intensive purposes "stops up" the fuel injector and keeps fuel from flowing through it. Numer 6 is the pintle seat. Think of this as the drain in your tub. It is the piece of metal with a hole in it that the pintle stops up. When the coil is energized, it becomes magnetized. This magnetic force pulls the pintle up away from the pintle seat allowing fuel to pass through the injector. When a car sits for a long time, the fuel in the injector degrades and separates releasing gums and varnish. As time passes and the fuel evaporates and degrades, whats's left is the gummy mess that clogs up the injector. When dry, it effectively "glues" the pintle the the pintle seat. Cleaning: Now that we know the basics of how an injector works and why they get clogged or seized, lets look at what we need to do to clean them. The basic strategy is the same whether clogged or seized but the approach is going to be a little bit different. The first thing we have to do is devise a way to pulse the injector out of the car. The next thing we will need to do will be to get the injector operable meaning we need to make sure the pintle is moving up off of its seat. This step won't be necessary if the injector is just clogged. Then we will want to do the actual cleaning, and finally we will replace the feed hoses and O-rings before reassembling the unit. Supplies Here is what you are going to need. 2 bottles of 91% isopropyl alcohol 1 small eye dropper 3 tupperware containers - 2 must be able to hold all 6 injectors and the cold start valve fully submersed in alcohol. The third needs to be slightly longer so that you can have good access to the injector while submerged. 2 lead wires with alligator clips electrical tape 6 to 8 D batteries Paper Towel (preferably shop towels) or a cloth Piece of cardboard or other suitable work surface Procedure: ​Now that you have all of your supplies it's time to get to work. Obviously the first thing you will need to do is remove the injectors from the motor. if you do not know how to do this I highly recommend you get yourself a factory service manual. There are also numerous how-to's online. Once you have everything together, find a comfortable place to work, I laid a piece of cardboard over the kitchen table and worked there but anywhere reasonable clean will do. Place all 7 injectors in one of the containers and fully submerse them in alcohol. Let them soak for about an hour, longer being better. Now take your other container and fill it with enough alcohol to submerse all 7 injectors (Don't forget your cold start valve!) and the other longer container with about 2 inches of alcohol. Place these to the side. the long one will be our working bath and the other one will be our clean bath for the injectors to continue to soak after we've worked on them. In order to clean the injectors, we must cycle them open and closed. To do this we will need to come up with a way to run a current through the injector. In our cars, the 12 volt current from the battery is routed through a dropping resistor that drops the voltage from 12v to 3.5v before it is passed through the fuel injector. So, ideally what we want is a 3.5v current that we can turn on and off to pass through the injectors. You could come with a whole bunch of different ways to do this depending on how fancy you wanted to get but my method is simple and easy and ver effective. If you did not know, a standard D battery output is 1.5v (actually AA, AAA, C, and D batteries all output 1.5v). By combining 2 D batteries in series ( + to -), the output voltage is bumped to 3v. This 3v current is very close to the 3.5v used in the vehicle so it will be perfect for replicating the pulse the injectors get in the car. So, what you will want to do is take two of your D batteries and tape them together so that the + side of one battery is touching the - side of the other. Now, grab your wires with the alligator clips and tape on end of one of the wires to the + one of your battery pack you just made. At this point you are ready to grab one of your injectors out of the alcohol bath and start disassembling and cleaning the exterior. Remove the bottom O-ring as well as the aluminum spacer on the main body. once the spacer is off you can remove the thin metal piece that sits right on top of it. Now you can work the thicker rubber O-ring off the main body of the injector and go to town cleaning. I used a toothbrush and some paper towel to get the outside decently clean. This isn't crucial but it will help to keep your cleaning bath free of contaminates. After you are happy with the cleanliness of the injector go ahead and attach the other end of the wire to one of the pins coming out of the injector plug. It doesn't matter which one since the magnetic field will be the same regardless of which direction the current is flowing. Go ahead and wrap the exposed metal of the alligator clip (if there is any) with some electrical tape to minimize the chances of the negative clip contacting it when she attach it. Speaking of the negative clip, go ahead and grab your other wire and attach one one to the other pin coming from the injector plug. What you should have now is as follows, -[ ]+-[ ]+ ----------Injector--------- in case mtg diagram doesn't make sense, you will have your two batteries taped together with one end of a wire taped to the positive side and the other end of that wire attached to one of the pins on the injector. From the other pin on the injector you should have another wire which is not currently attached to anything. Now if your car has been sitting for years, it is not uncommon for the injectors to be seized shut. If this is the case they will not open and will not spray any fuel. After all, that is the reason for this article. It is important that you remember that the injector is an electromagnet pulling the pintle off the seat with magnetic force. If the injector is seized then what that means, is that the magnetic force pulling up on the pintle is not great enough to overcome the force of the gunk holding the pintle down. So how can we free it up? First we need to see if that long soak in alcohol was enough to free it up. So go ahead and touch the free end of the cable coming off the injector to the negative end of your battery pack. It is good practice not to keep the current flowing throughout the injector for too long. If you hold it too long you can actually burn up the coil inside the injector and then you will have to replace it. Since we are only using 3V that isn't likely but better safe than sorry. If you are lucky, you will hear a click come from the injector meaning that the injector did actually open up. However, if you are like me, the injector will still be stuck. So what to do? Well, if you have ever taken physics then you may know what to do, but for those who haven't or are a bit rusty, heres a little physics lesson. Voltage is the potential difference across two points. Current is the rate at which the electric current flows. Resistance is the resistance to the flow of electricity. Voltage, current, and resistance are all directly related by the formula V = IR. V is voltage measured in volts, I is current measured in amps, and R is resistance measured in ohms. How does this apply to an injector? Well, the resistance of your injector is constant and does not change (unless you have a faulty injector that should be replaced) the variable that we can control here is the voltage that we send through the injector. By increasing the voltage, we are also increasing the current that the injector draws. That same formula above can be rewritten as I = V/R which mean that the current is equal to the voltage divided by the resistance. The resistance of an injector varies based on the application but lets assume here that our injectors resistance is 10 ohms. We just attempted to actuate the injector with a 3v pulse so let's calculate how much current that was. 3 volts divided by 10 ohms comes to 0.3 amps of current. Now, we know that 0.3 amps of current is not enough to break our injector free so how do we increase that? well, as we've learned we need to increase the voltage. to do this you need to simply tape one more battery in line with the other two making sure to put the + end of the battery to the - end of the other. this will increase the voltage by 1.5v for a total of 4.5v. This will bump our current to 0.45 amps. now try tapping the negative lead to the negative end of the battery and listen for a click. Tap it 5 or 10 times and if you still don't hear a click add another battery to the line and try again. Keep adding batteries one at the time until you get the injector to unstick. You can add up to 8 batteries in a row without risk of damaging the injector. The faster but less optimal way to do this would be to use a 12v car battery right from the get go to unstick the injector. this would be fine as long as you use short pulses of energy and do not hold leads on the battery for too long. At this point you should have gotten the injector to unstick and are ready to start cleaning it. If not, you will have to seek out another option for fixing your stuck injectors. The actual process of cleaning the injector is easier if you have a buddy to pulse the injector for you while you do the cleaning. So, assuming you do, have them start pulsing the injector while you force alcohol throughout he top with the eye dropper. do this for a few minutes and then do the same thing but this time forcing the alcohol though the nozzle end of the injector. During the process you should see dirty gunky fluid come out of the injector. repeat this until the fluid that comes out is clean and clear. Do note that it will only drip out and won't be any sort of stream of flowing. After you are done cleaning, place the injector in the clean alcohol bath until you are done with the remaining injectors. Repeat the above process for all 6 injectors including the cold start valve. The cold start valve was designed to run off of 7 to 12 volts so it may take a few batteries taped together before it will click open. Congratulations! You have successfully cleaned your injectors! Now we need to get the old hoses off and replace them as well as the O-rings. If your injectors are like mine, then you have hoses held on by small metal cups. I tried cutting the hose with a blade and pulling it off, but I could not for the life of me get the hoses off so I decided I would have to cut the metal cups. For this you'll ned a dremel and a razor blade along with a pair of pliers. This is the bit we will be grinding off. Before trying this, be sure to try and just pull off the hoses after you make a slit down the side with a blade. It may work for you and will save a big hassle! Hold the injector with the pliers and carefully start grinding away the metal cup. when you think you've ground off enough try and peel it away as best you can to expose the hose underneath. Now cut down the side of the hose to the base with the razor blade. Get your pliers and start pulling the hose off the injector. It will be really difficult but just keep twisting and pulling until you get it off. Once the hose is off, the cup will just slide right off. Replace the hoses with new fuel injection hose and clamps. Please be sure to use fuel injection hose and not normal fuel line. Now we can replace the O- rings and slide the thin metal piece and aluminum spacer back on. It helps to lube up the o-rings with a dab of motor oil! Now you are ready to reassemble everything and fire it up! If the motor has been sitting it would probably be a good idea to replace all the rubber fuel hose and clamps as well as the fuel filter and spark plugs! Thank you for checking out my writeup! I hope it helps you out!! -Blake

- 5 replies

-

- Fuel injector

- DIY

-

(and 7 more)

Tagged with: