NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

There's a lot of good stuff about rods in the Honsowetz "How to Modify.." book. Stock, sports-option, race-prep, oiling holes, rod bolts, etc.

-

I thought the issue with rods was RPM, not power output. Inertia at the top of the stroke. So it would depend on how fast you intend to spin the crankshaft, mainly.

-

Starting a 77 280z restoration

NewZed replied to JakeMonkey's topic in S30 Series - 240z, 260z, 280z

3. I would bet an R200 that the car already has an R200. The blocks are all pretty similar. People run turbos on all of them. It's the pistons and head combinations that need to be planned. Since you're starting from scratch, you might as well put together the engine you want to get the power you want and start with aftermarket engine management. http://forums.hybridz.org/topic/50208-the-ultimate-l28et-guidewhat-you-need-for-350whp/ www.blackdragonauto.com apparently has 204Z bumpers. That's the most popular swap for the big bumpers. -

Sounds a whole lot like a bad battery cable connection. One of the big wire connections. Loose/dirty/corroded, the resistance from the current pulled to turn the starter motor heats up the connection and it opens. Cool down and the connection comes back. It's actually pretty common, it almost got me a year ago. If you have the bolt-on on cable ends, check those, also the typical post/connector interface. The clicking relay is probably coincidental to the power loss when the connection opens.

-

1987 has self-diagnostics with trouble codes. Pretty easy and might hep. EFEC. http://www.nicoclub.com/nissan-service-manuals

-

Give some history on the car. It could be an old turd that's been sitting for 12 years, or a daily driver that ran perfectly until you started having problems. Vacuum leaks fit the second symptom. FPR or fuel pump leaking down, the first.

-

http://www.wolfcreekracing.com/index.php?option=com_content&view=article&id=22:tranny-a-rear-diff-parts&catid=16:tranny-a-rear-diff-parts&Itemid=31

-

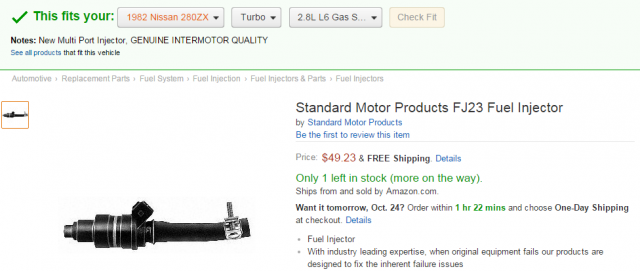

Some of those look like Standard brand aftermarket injectors. If you don't know how old they are or what condition they're in you should probably get them checked or check them yourself. Fill some Coke bottles while they sit on top of the engine. You'll see how it sprays then.

-

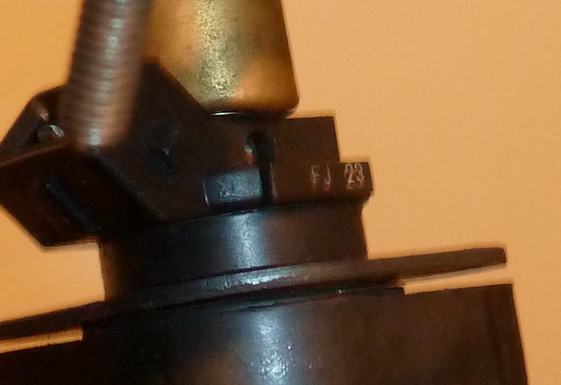

Does your camera have a close-up function? Can't really see in there. It does look odd, but it might just be designed for shooting stream instead of a cloud. You could have posted pictures of the other injectors for reference. Or a shot of the injector body since that's about the only way to tell the Z and Zx injectors apart, by color. Aftermarket has number/letter codes though, so those would tell something. Really, you haven't given much of a clue. Basically, a picture of a metal tube and some seals. The one that doesn't matter, #3, looks like a Standard brand FJ series, If it was NA for a 280Z it would be an FJ707T.

-

So DIY got back to you and told you that you had the wrong injector setup? Narrow your thought process down from "exploding computer" to "overloaded injector control transistor" if you want to get back on the road. You'll need a soldering iron.

-

I kind of jumped ahead and back and forth in the story but I got the impression that you did not have the spark plug properly grounded. That would be one reason for no spark when testing. Normally the ground strap of the plug grounds through the threads of the plug, which are in contact with the head. Yours are hanging in mid-air. When you hold them in your hands they are also ungrounded unless you are touching the block or the body. Even then, if your hands are dry and calloused, you'll get a poor ground. It's a bad idea anyway since they'll give a good shock. Set the plug on the valve cover with the threads making good contact with the metal. Or run a jumper wire fromthe ground strap to the body or block. Then look for spark.

-

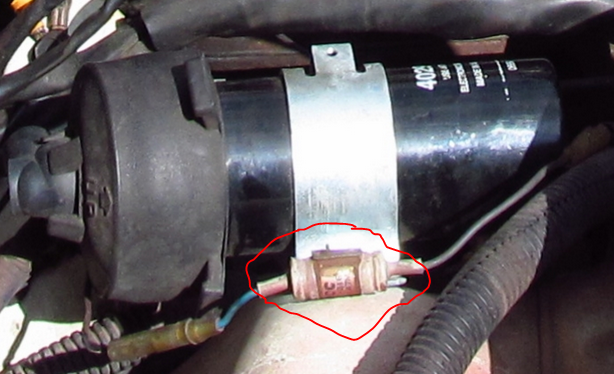

If you mean the thing I circled in red, that's a capacitor, aka condenser. They do go bad occasionally. I see no ceramic pieces. The miss on the condenser makes one wonder what you meant by ignition control module. The coil looks stock. Might be worthwhile to browse through the FSM, Engine Electrical, and make sure you're getting the names right, at least. There are some parts on the ZX type distributors that can break after many miles.

-

1979 didn't have a ballast resistor. Not clear what you're really working with.

-

Learn how the engine management works. Take some measurements. There is no easy path back to 100 mph speed runs. http://www.nicoclub.com/FSM/280z/

-

https://www.fairchildsemi.com/datasheets/TI/TIP42.pdf I took a quick look around the internet but couldn't find an MS board that looks like yours. It could be your injector driver/transistor, based on specs. and what injectors need. BUT, the white stuff might just be heat transfer paste. Not really a sign that it's no good. Did the guy just stick his nose down on the part and proclaim it as bad? It's easily replaced, if it is. Could also just be that the paste shorted the connections. Maybe. You should at least find out what kind of Megasquirt you have. There are several varieties.

-

Sounds like your injector drivers might have failed open. Probably flooding the engine until the fuse blows. Or you have a short at the power supply to the injectors. Just guessing. You could disconnect the injectors from board to check for a short. The drivers themselves will take more work. Some random links... http://www.diyautotune.com/tech_articles/megasquirt_injector_driver_troubleshooting.htm http://www.msextra.com/forums/viewtopic.php?f=131&t=51994

-

Kind of sounds like Kind of sounds like the ignition switch stopped working, and Start only gave On, with no starter action. So the PO messed around with the wiring to make it run. Added the push button to fix the no starter action problem, and maybe hot-wired the ignition relay. It shouldn't click when the battery cables are connected. That will drain the battery. Does the car turn off with the key or do you have to drop the clutch with the brakes on? The hot fusible links, with the T plug behavior, is probably a separate problem. Maybe a bad alternator or voltage regulator. You'll have to dig around and see what else has been messed with. There's probably more messed up than just the starting circuit. Look for extra loose wires T'ed or spliced in where they don't belong. The wiring diagram for the ignition switch circuit is pretty easy to understand.

-

You should re-think what's happening and write a new description. Most of your post doesn't make sense. Read it back to yourself and you'll see.

-

limiting front differential mount movement

NewZed replied to whatnow123's topic in S30 Series - 240z, 260z, 280z

The link in Post #10 seems to work fine. Goes directly to a picture. -

The process of elimination should work for you. There's only two left, right, and one of those is supply. Or you can go back the the tank and blow air through the lines connected to the ports shown in the Fuel and Exhaust (FE) chapter (not the Engine Fuel System chapter). Always good to confirm anyway. But it looks like the 1973 internet resources don't have that chapter. Could be why you missed it. So 1972 or 1974 will have to do. Here's a good resource for those- http://www.nicoclub.com/datsun-service-manuals

-

Your original guesses were correct. Liquid should not be returned to the reservoir. You have the wrong line connected. There is a specific port for returning fuel to the tank. Labeled drawings are in every FSM, in the Fuel and Exhaust chapters. Look at the pictures and you'll probably be able to figure it out.

-

Attach links to the threads you've read so people don't waste time referring you to them. There was a very good one recently on this exact topic.

- 4 replies

-

- connections

- harness

-

(and 4 more)

Tagged with:

-

Just to help you with your original question, I'll rephrase it - How many of you would pay $350 for a set of brackets that will let you use Z32 calipers and rotors, front and back, on your S30's? You'll need to source the other parts yourself. So add in the cost of the calipers, rotors, pads, and any assorted hardware to make it work, and you have the cost of the "kit". It's interesting to see how new products are developed. Best not to be too sensitive to criticism/questions, especially when it's just one of many ideas out there on the interweb.

-

Because there's no market for them. Nobody wants them. That's how business works. Make a set and show the value. You said they're worth $300 to you, and you have a car to put them on.