NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

280z Rear Disc Conversion, Sport Kit from ZCarDepot

NewZed replied to Boog's topic in Brakes, Wheels, Suspension and Chassis

I don't know that system exactly but I've worked brakes in general. It looks right to me. Just make sure that the passage from the bleed screw to the caliper piston cylinder hits the cylinder at at the top. You can see the casting marks from the outside. The calipers are designed for a certain orientation and the bleed screw is positioned for convenience. The screw might might be right, but the passage might enter low. Think about air bubbles.- 5 replies

-

- brake conversion

- rear disc

-

(and 2 more)

Tagged with:

-

CS144 Alternator is not charging battery

NewZed replied to tamo3's topic in S30 Series - 240z, 260z, 280z

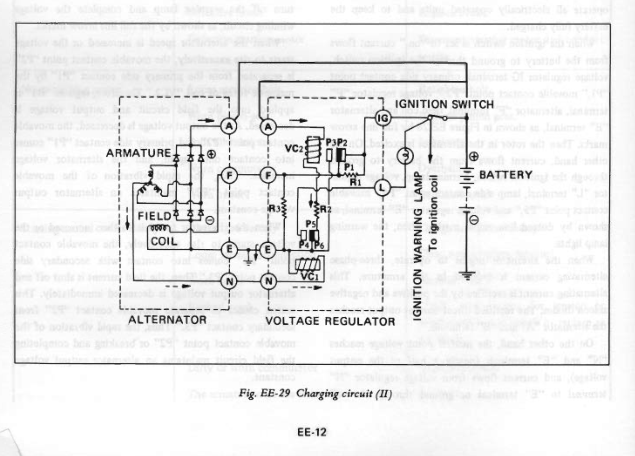

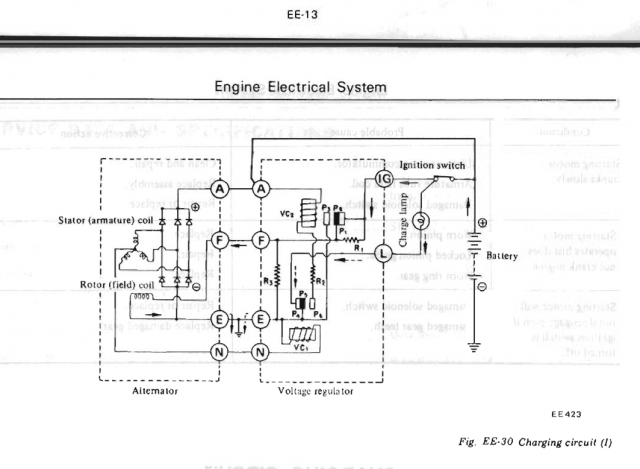

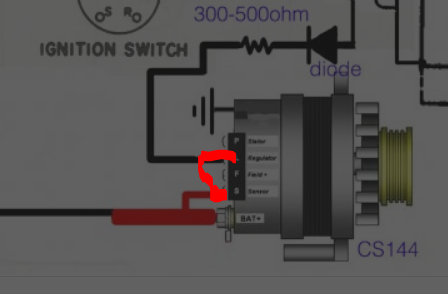

People don't seem to be reading each other's posts. My images were from what is supposed to be a 1975 FSM. I've seen discussions about whether it actually is in the cars. It might be that Nissan used old images but never put the light in the early Z's. Even the 1972 FSM shows a Charge lamp, and it has an ammeter. I suggested that the Charge lamp might be burned out also. Maybe Charge lamp and Warning lamp are not the same. Who knows. In the 1972 image they call it a Warning lamp, see below, in 1975 they call it a Charge lamp, see my previous post. Your image is from the models with a "starter interlock", and they've cut out a portion of the diagram. The arrow starts from nowhere. The ones I inserted show the circuit back to the ignition switch. They all go to "L" on the voltage regulator though. "S" is typically connected directly to the battery positive, at the starter lug, where the positive cable attaches. If you attach L to S there will be a constant draw on the battery, through the windings. That will probably drain the battery. Whatever you decide to do, use your meter to confirm that you have power on the wire. -

Question about dual master cylinders...

NewZed replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

There are workarounds. https://www.google.com/search?source=hp&ei=Lr5FWvq0CIbmjwO3rr6wCQ&q=photobucket+fix&oq=photobucket+fix&gs_l=psy-ab.3..0l10.2378.8124.0.8334.15.9.0.6.6.0.126.597.8j1.9.0....0...1c.1.64.psy-ab..0.15.658...46j0i131k1j0i46k1j0i10k1.0.opuekT9VkiA -

CS144 Alternator is not charging battery

NewZed replied to tamo3's topic in S30 Series - 240z, 260z, 280z

As ben a implies, apparently the L circuit of the GM alternators is sensitive to current. So, a resistor or a light needs to be in the circuit. Your test was probably okay on it, but if you ran it that way it might be damaged by heat build up. You should be able to figure out why the wire in your harness does not have voltage. That wire should have the right resistance since it has a charge lamp in the circuit. I have heard of the charge lamp burning out. It's not common but it might explain why you don't have power on the wire. I don't know exactly where it is in the 75. In the ammeter most likely. My 76 has a voltmeter, as does 77. Your 75 does not have the wiring of a 77. Here's a 75 diagram. I think that I got it from the atlanticz web site. Also, the charging circuit from the 75 FSM, showing the charge lamp. Also got that from atlanticz. 75_280z_wiring.pdf -

Building a race car.. looking for advice!

NewZed replied to jsausley's topic in S30 Series - 240z, 260z, 280z

It's "scrimp", not skrimp. -

If you had waited nine days you could have claimed a clean ten year necropost award. 2008 to 2018. Is your statement actually a question?

-

CS144 Alternator is not charging battery

NewZed replied to tamo3's topic in S30 Series - 240z, 260z, 280z

A simple test of the alternator's function, which would also tell something about the charge lamp wire from the harness would be to run a jumper from the L terminal to the S terminal, right at the alternator. That will power the L terminal, assuming that S has power. The alternator should start charging then if it is on proper working order. If it works then you can go back and figure out what's wrong with your harness, with a little more hope. Posting now even though TimZ has replied... -

Just curious - how can you sell a car that does not belong to you, at least in the eyes of the law? No title. Do you have any documentation showing paperwork back to the last owner of record? Otherwise, how does a person know it's not stolen? Did you get paperwork when you bought it, or did you just give somebody some money and tow the car away?

-

72' Distribution Valve

NewZed replied to M_Motorsports's topic in Brakes, Wheels, Suspension and Chassis

You have air in the system. Sounds like the calipers based on how far the pedal travels. The best way to understand where the bubbles are is to examine the caliper castings closely and figure out where the hole from the bleed screw enters the piston bore. Often the hole is drilled at an angle and if you put the bleed screw at the top the entrance to the hole will be below the high spot. You can bleed them a hundred times but the bubble will never exit the caliper bore if it's above the bleed port. Position the calipers so that the entrance to the bleed hole is at the highest spot. Sometimes you have to unbolt the caliper and angle them correctly before bleeding. -

That's a nice schematic. It doesn't really explain the 5 volt signal though, or how to wire up a CAS on the bench for testing. Looks like DIY has repurposed Nissan's original design. I'm sure it's clear to somebody out there. If it is maybe they can add some detail. How to wire it for standalone testing and what to measure when testing. Volts or continuity, on which wires.

-

I think that what's not clear, at least to me and maybe cgsheen knows for sure, is whether the 5 volts is passed through the CAS, where the CAS is a gate for 5 volts generated by the ECU, or if the 5 volts is generated within the CAS. If it comes from within the CAS then powering those other CAS wires should give the 5 volts as expected. If the 5 volts comes from the ECU, you're not going to see it, with a battery and jumper wires test. If you do cg's test, which I've done, with the CAS/distributor plugged in to a Nissan harness, you'll see the 5 volts. But I've not tested the wires from the ECU to see if they had 5 volts to start. Easiest test for you might be to find a buddy with the proper Nissan who will let you unplug his CAS and plug in yours. Turn the key on and spin the shaft by hand as described, with a meter attached. I was able to do my test because I had a Pathfinder in the driveway. It works.

-

-

The thermostat stays closed until the coolant in the engine reaches desired operating temperature. But your engine isn't heating heat up properly on the road, it just stays cold. And you live in the Bay area. It has to be producing enough heat to reach thermostat opening temperature. The radiator removes enough heat to keep the thermostat at the point of opening and closing, if enough air is flowing through it. But your engine goes above the thermostat set point eventually, in traffic. Seems like your fans aren't moving enough air. And running one pusher and one puller is odd. Maybe remove one, it's probably blocking or screwing up the other. Even better, remove both. Besides that, you haven't said if you're actually switching the "traffic" fan on in traffic. But you really shouldn't need it anyway. You've over-engineered, for a problem that doesn't exist. Those are two big clues, the staying cold on the road, and overheating while stopped. You have a plain old L28 and with stock parts in good condition shouldn't be having any problems at all. Focus on the basics. Maybe get rid of the electric fans and go back to what has worked, and still works, for millions of cars. Mechanical fans. Then you can put a stock temperature sender in and get rid of the Autometer gauge problem. Once you make it work the way it was intended to, you can put those parts back one at a time.

-

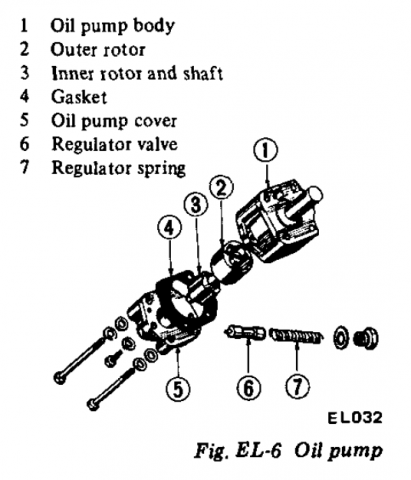

I think that I misread your post. I was thinking that you dropped the whole pump and the distributor shaft fell out. You should be able to just put the pump back together without worrying about orientation. Turn the rotor until is drops in to place. Still doesn't hurt to read the FSM to understand how things work.

-

Looks like you might be overthinking some things and underthinking others. Close the heater valve and run with it closed, and determine what happens. It's very important. It might not be the source of your problem but you need to know.

-

Follow the instructions in the Factory Service Manual. Engine Mechanical and Engine Lubrication chapters both have them.

-

The thermostat staying shut will cause the engine to heat up no matter what radiator you have. It's the only outlet from the head and engine. High pressure from a good pump might cause a bad thermostat to blow open though. Couldn't tell if your "new" thermostat was new new or new old. If you're using old thermostats try getting a new Nissan brand thermostat and starting over. You might improve getting to operating temperature but still have the creeping to 205 problem. They still have cross-reference charts to new thermostats. You can get one at your local Nissan dealer.

-

The coolant gushing out problem just came up in another forum I hang out on. I had the same thing happen with my old clogged radiator. I think that it means that the radiator is not passing enough fluid to supply the pump inlet. The bottom hose has to be collapsing, causing an overall system volume decrease, and the coolant gets pushed to the top side. But the gushing is a sign that the thermostat opened. First though, you might try just closing the manual coolant flow valve through the core completely, and see what effect it has. It should force more fluid through the block and head and thermostat housing. If you see an effect it will be a clue about at least one of your problems.

-

Is your fan on a temperature switch or does it use a controller? Where is its sensor located. The fact that the temperature creeps up to 205 shows that you have a cooling problem. The thermostat is actually a heating device. It stays closed until coolant temperature reaches its set point. But the coolant has to flow past the thermostat in order for the thermostat to equilibrate to the same temperature. So you actually have two odd problems. Do you have your heater core bypassed? Maybe the pump isn't pushing enough coolant to heat up the thermostat, with the bypass, and also not pushing enough to cool the engine.

-

If you're sure that everything is right then the only solution is to replace the pump. Because it went bad, it had to have gone bad. It must be the pump because you are positive that everything was right when you put it together and magic would be required for anything to change. See the logic problem? If you're positive, then the only thing left is a bad pump. Maybe try a different brand of pump.

-

You already had one bad pump. Maybe you got another. Switching carbs won't fix a bad fuel pump. Have you confirmed a good power supply and good grounding? That's a very basic electrical component troubleshooting step. Are you running it deadheaded or using the return lines. Are the return lines open? Are you using a filter before the inlet? Does it flow enough to supply a gravity fed pump? Those inlet filters can cause a lot of problems. Doesn't seem like you've double-checked the basic stuff. It worked for a while you should be able to make it work again. If the pump's not designed to deadhead or if you're cavitating due to inlet restriction you can wear the pump out faster.

-

Ford Super 8.8 irs swap thread. Rear brakes too

NewZed replied to Invincibleextremes's topic in Drivetrain

Isn't this almost exactly how the last 8.8 project started? Deja vu...- 282 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

You know, it didn't work for my email. I see your @ but did not get an email. I think that notifications have to be set to get emails. You might send him a PM by hovering over his avatar.

- 51 replies

-

He was on zcar.com a few days ago. http://www.zcar.com/forum/10-70-83-tech-discussion-forum/412105-brake-issues.html Does the @ function work on Hybridz? @NewZed @AlbatrossCafe Yours looks wrong. @cgsheen

- 51 replies

-

Diff Swap Affecting Brakes?

NewZed replied to nicksoccer22's topic in Brakes, Wheels, Suspension and Chassis

The brakes are completely separate from the differential. You could install a Ford, Chevy, Mopar, Suzuki, Yamaha, Kia, etc. differential and not have to touch the brakes at all. At all, no bleeding, adjusting or anything, not even the parking brake.