NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

You'll need to make the tough decision of Phillips head or straight blade. It's possible though that either will work. It would really be nice if Nissan had put more detail n to their drawings.

-

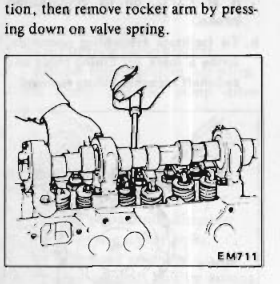

Can't be that hard. The manual says just "replace pivot". After removing the rocker arms.

-

Try your local dealer. Cheap. http://www.carpartsmanual.com/datsuns30/DatsunZIndex/PowerTrain/TransmissionControl/4Speed/FromSep-71/tabid/1717/Default.aspx http://www.courtesyparts.com/pin-p-345015.html

-

Good luck finishing, if you're stuck on this, after four people have told you two different ways to get it done. How are six 6 ohm resistors from the internet different from six 6 ohm resistors from the 280ZX Turbo? One path to follow might be in the answer to that question.

-

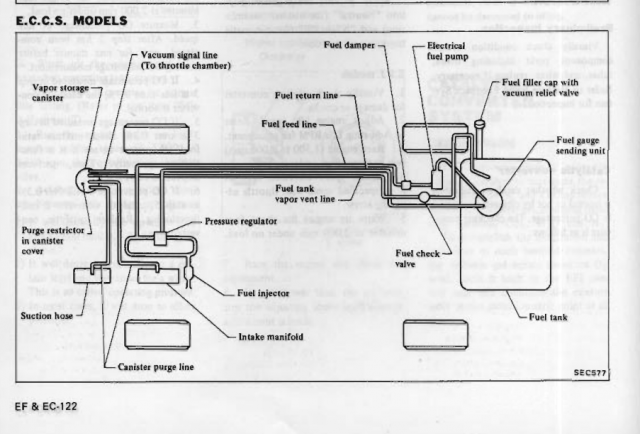

Wrote some stuff then realized that if you had a relay or AFM switch problem the car should still start, run for a few seconds, then die, if the pump runs when the key is turned to Start, as you describe. When the key is at Start the rail should pressurize and things should work as they're supposed to, injectors and cold start valve. Your problem lies somewhere else, not at the pump or AFM. Have you checked for power to the injectors? Continuity to Pin 1 from the coil negative post? You should open the Engine Fuel chapter and Body Electrical and make sure the fusible links are all in good shape and everything is connected correctly in the EFI harness. Download the Fuel Injection Guide also, for the diagrams, and additional advice. Use the 1980 Guide, it has early and late models included. Test from the pins at the ECU connector. You'll waste time and money if you start guessing and swapping. http://www.nicoclub.com/datsun-service-manuals http://www.xenons130.com/reference.html

-

You're welcome? The new link works. The images in your LT1 swap post are broken. Good luck with the venture, looks like work.

-

You are waaaaaaaaaaaaaayyyy ahead of yourself. First impression is disappointment - there's nothing there except a "Coming Soon" sign. Did I just load a virus on to my system? Put some stuff on there and come back when it's worth a click.

-

Check for spark. If you have spark, try starting fluid. If it fires and runs right, then dies, you'll know you have a fueling problem. If you can't hear the pump running, that could be the fuel pump contact switch in the AFM, Easily fixed, if so, no need to replace the complete AFM. Could also be the fuel pump relay, or the fuel pump itself. But, as you've deduced, the pump should run with the key On and the flap open. I have had material get on the the AFM fuel pump switch and stop it from working. If you take the cover off of the side of the AFM you can see the switch arm, that pushes to tiny contact points together. A speck of dust can block contact. You could jump it with a screwdriver if you want to test it, or polish up the contact points.

-

That's a nice looking setup, with the custom supply and return lines. Are you making those or piecing your own package together? Designed for the stock Nissan two port FPR's?

-

The 280Z's were designed for half-shafts with R200's. It would be odd if they were binding and even if they did I think it just pushes the strut outward, and/or causes the suspension to bind. What brand of u-joint did you break? Just for the record. Might be cheaper/easier to find half-shafts like RZ suggested, that have the precision-fitted factory u-joints. Nissan put a lot of effort in to making the u-joint fit perfectly.

- 23 replies

-

- axles

- halfshafts

- (and 4 more)

-

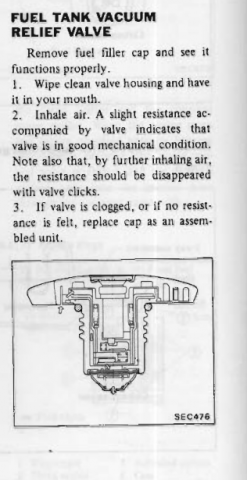

That's different than a 280Z's. But that's what "vacuum relief valve" means on the diagram I attached. If you have a mighty vac you could probably rig something up to see if the valve opens. Or if no one is looking you could suck on it, procedure described in the attached picture. By the way, all of these pictures come from the final few pages of the 1983 EFEC chapter.

-

If it's not just your imagination, it seems like tank venting might be involved. Not through the cap but through the charcoal canister and its vacuum lines and vent hoses. It may be that it's not lack of fuel but overpressure. Just a guess. Maybe you're boosting the fuel tank. The cap should have a little spring-loaded valve on the inside center. Take a look. You can pick it open with your fingernail. It lets air in but none out.

-

Don't forget that the fuse is just a thermal overload device. Heat from other sources can push them over the edge. Maybe your relay board is in a hot spot. The pump motor failing from overheating is not the same as the fuse blowing from excess current and overheating. If the fuse was sitting next to the pump where heat could be conducted through the wire to the fuse that would make some sense but the relay board is probably 12 feet away from the pump. It doesn't see any pump heat. You said that you have the stock tank with stock return lines but the only car in your sig with MS is a 73, which has the small return lines. Probably not the specific issue though, since if you had back pressure at the return line your fuel pressure would be uncontrollably high. Edit - the older 240Z fuses were known to blow and/or melt their surroundings due to poor contact at the fuse, allowing corrosion and a high resistance connection. It's resistance at the fuse area that produces the heat that blows the fuse. Increased resistance at the pump lowers overall current draw and saves the fuse. If pump motor resistance drops when it gets hot that could cause excess current through the fuse. Focusing on heat is right, but the general "heat is bad anywhere" view isn't going to get you there.

-

I'm not sure this logic works. There's a lot of fuel available for cooling, if it's flowing. Why don't you get rid of the pre-filters for a while and see what happens. Or at least confirm that the flow rate of the filter matches the flow rate of the pump. 100 micron particles probably require a pretty large surface area to allow a high flow rate. "100 microns" doesn't tell enough. Also not clear on how a hot pump draws more current, causing the fuse to blow. A non- or slow-spinning DC motor draws more current, I believe from my limited electrical knowledge. But a hot motor, maybe not so much.

-

What could prevent injectors from firing.

NewZed replied to ISPKI's topic in Trouble Shooting / General Engine

Pin 1 at the ECU connector needs to be connected to coil negative, and the tachometer and its resistor need to be in place. The tachometer is also connected to coil negative and has an effect on the Pin 1 signal to the ECU. I don't know exactly what range the ECU works in so a meter reading probably wouldn't tell very much. -

Fairly common. Shouldn't be very hard if you have the EFI harness from the 280Z or ZX. Details returned proportional to details given.

-

What could prevent injectors from firing.

NewZed replied to ISPKI's topic in Trouble Shooting / General Engine

Probably a Pin 1 problem. The ECU needs to know what's going on. -

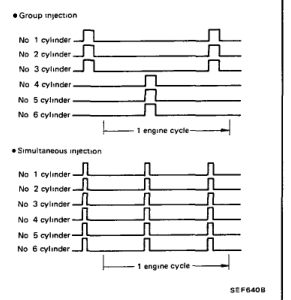

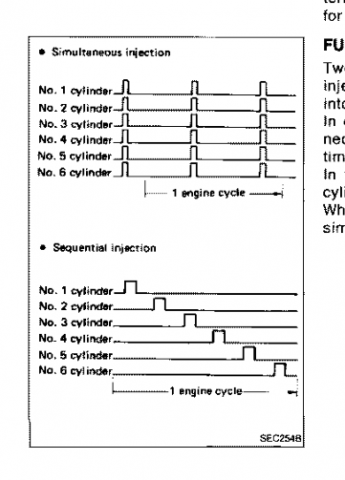

"VG30E" isn't really very specific. For instance, Nissan went to sequential injection in 1990 for the 300ZX, which would be a nice upgrade over batch or semi-batch. I would think a 1990 to 1995 VG30E system might be the way to go. Somewhere in the 90's I think the systems got extra complicated, maybe 96. But pre-1990 might not be the way to go when there are tons of the early 90's VG30E cars out there. Pathfinders and Maximas, for example. cgsheen has done the swaps though so would know better.

-

1976 280z Fuel/voltage gauge, and 3.90+ R200 in pacific NW

NewZed replied to mtnickel's topic in Parts Wanted

Any or all of the three here could have a 3.9. Might be within distance for you. http://row52.com/Search/?Year=&LocationId=0&ZipCode=97225&Distance=250&MakeId=&ModelId=1572&Page=1 -

https://www.diyautotune.com/softwarelinks.htm

-

260z - Rebuilding L26 engine? Drivetrain?

NewZed replied to jezzza's topic in S30 Series - 240z, 260z, 280z

The cams have letters on the back, and the heads have numbers and letters at the bottom front of the head. No need to look for square ports. -

Four year old fuel?

-

This is why you need to just start bolting things together. Then you'd know that the water pump doesn't use the AC idler.

-

Hydro-locking bends connecting rods. Have you had the engine apart yet? You might need more than pistons. How can you collect parts if you don't know what you need? Curious on how that much water got in there. Did you not have an air filter?

-

Automatics use a different bar. You can get a new one for $314 from Courtesy. http://www.carpartsmanual.com/datsuns30/DatsunZIndex/Axle/RearSuspension/tabid/1731/Default.aspx